6061 aluminum tubing is one of the most widely used materials in modern manufacturing. Because it is strong, rust-resistant, and easy to shape, it is a popular choice. Engineers, designers, and fabricators in many fields prefer it. Whether you’re building aircraft components, custom vehicles, or industrial machinery, 6061 tubing delivers dependable performance.

In this guide, we will look at 6061 aluminum tubing. We will compare its tempers, like 6061 T6 and 6061 T9. We will also help you understand how people use it in the real world. We’ll also highlight how it differs from standard aluminum pipe, helping you choose the right product for your project.

What Is 6061 Aluminum Tubing?

6061 tubing is made from 6061 aluminum alloy, part of the 6xxx series. This alloy contains magnesium and silicon as the primary alloying elements. Its widespread appeal stems from its balanced mix of features—moderate to high strength, light weight, and superb resistance to corrosion.

Aluminum pipe is often used to transport fluids and gases. In contrast, aluminum tubing is usually used for support, framing, and mechanical systems. It is manufactured in multiple shapes, including round, square, and rectangular profiles.

Key Properties of 6061 Tubing

When selecting materials for structural or mechanical use, 6061 tubing stands out due to its comprehensive performance characteristics:

Strength-to-Weight Ratio

6061 aluminum offers high tensile and yield strength while remaining lightweight. This makes it ideal for aerospace, automotive, and load-bearing applications.

Excellent Corrosion Resistance

6061 resists corrosion from moisture, industrial chemicals, and even saltwater—making it suitable for marine, coastal, or outdoor use.

Weldability and Machinability

6061 tubes are easily machined and welded using standard techniques. They can be joined without significantly compromising structural integrity.

Surface Finishing Compatibility

The material responds well to surface treatments such as anodizing, powder coating, polishing, and painting, enhancing its visual appeal and durability.

Availability in Multiple Forms

6061 tubing is readily accessible in numerous dimensions, wall thicknesses, and configurations, allowing for diverse uses from bespoke fabrication to large-scale manufacturing.

Understanding Tempers: 6061 T6 vs. 6061 T9

The performance of 6061 tubing depends largely on its temper, which refers to the specific heat treatment applied during manufacturing. The most common tempers used in structural applications are T6 and T9.

What is 6061 T6 Aluminum Tube?

6061 T6 aluminum tube is the most commonly used temper. It is a solution heat-treated and then artificially aged to increase strength and hardness.

Typical mechanical properties:

- Tensile Strength: ~290 MPa (42,000 psi)

- Yield Strength: ~240 MPa (35,000 psi)

- Elongation: ~8–12%

Common applications:

- Aircraft and drone frames

- Bicycle frames

- Automotive chassis and roll cages

- Industrial machinery

- Marine railings and structures

The T6 version has a good balance of strength and formability. This makes it great for parts that need machining, bolting, or welding.

What is 6061 T9 Aluminum Tube?

6061 T9 aluminum tube is a more specialized version. It starts similarly to T6, but includes additional cold working (like drawing or rolling) after heat aging. This increases its fatigue resistance and stress tolerance.

Compared to T6, 6061 T9:

- Has higher fatigue strength

- Performs better in cyclic load environments

- It is harder to bend, but holds its shape better

Used in:

- Off-road vehicle suspension systems

- Aircraft landing gear

- High-performance industrial robots

- Vibrating machinery or structural systems exposed to impact

If your application experiences repetitive motion, vibration, or high impact, the 6061 T9 aluminum tube offers longer-lasting performance.

6061 Tubing vs. Aluminum Pipe: What’s the Difference?

While the terms aluminum tubing and aluminum pipe are frequently used synonymously, they have distinct functions and adhere to different sizing standards.

| Feature | Aluminum Tube | Aluminum Pipe |

|---|---|---|

| Use Case | Structural, load-bearing, framing | Transporting fluids or gas |

| Size System | Specified by Outer Diameter (OD) and Wall Thickness | Specified by Nominal Pipe Size (NPS) |

| Shape Options | Round, Square, Rectangular, Custom | Mostly Round |

| Surface Finish | Often finished or anodized | Typically raw or painted |

| Common Alloy | 6061 | 6061, 6063 |

If you’re designing a part that needs mechanical strength, precision, or visual quality, choose 6061 tubing. If your project is plumbing or gas transfer, an aluminum pipe might be more appropriate.

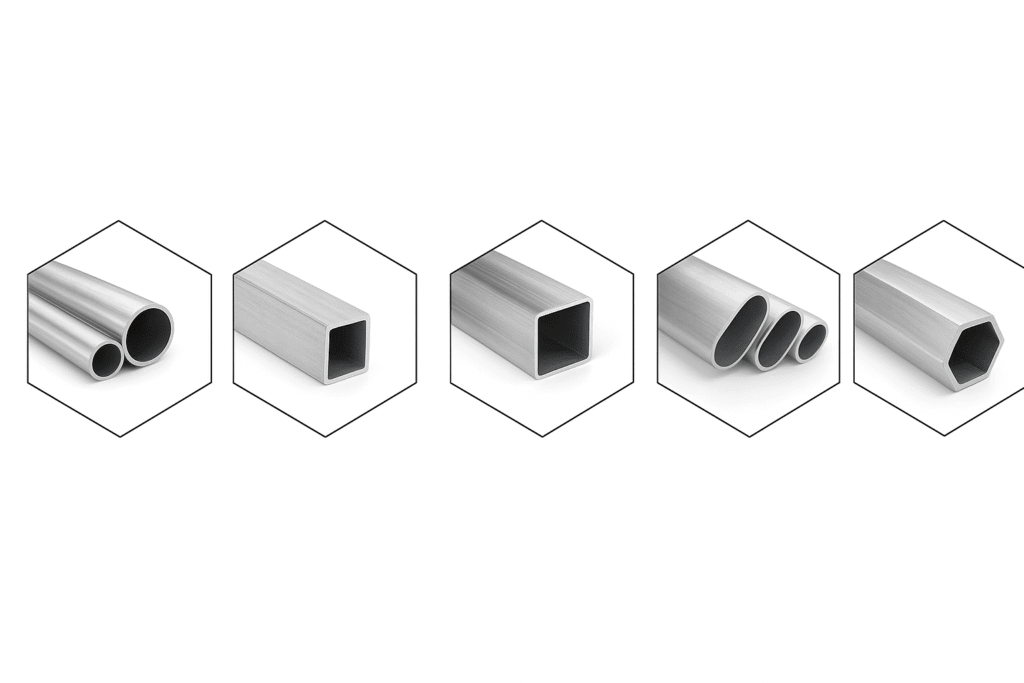

Shapes and Dimensions of 6061 Aluminum Tubes

6061 tubes are available in various forms:

- Round Tubing: Most common, used for general structures, vehicle frames, and pipes

- Square Tubing: Ideal for modular frames, gates, and architectural projects

- Rectangular Tubing: Used for platforms, railings, and surface structures

- Oval and Custom Shapes: For specialized or aesthetic applications

Standard dimensions:

- Outside diameter: 1/8” to 12” (3.18mm to 304.8mm)

- Wall thickness: 0.028” to 0.500” (0.71mm to 12.7mm)

- Custom lengths: Up to 20 ft or as per request

Most suppliers offer both imperial and metric measurements, and many provide cut-to-length or CNC fabrication services.

Common Applications of 6061 Tubing

Aerospace & Aviation

Used for wing spars, fuselage components, brackets, and hydraulic tubes due to its light weight and strength.

Automotive

Applied in performance vehicles, roll cages, chassis, intake manifolds, and lightweight body structures.

Marine

6061 tubing resists saltwater corrosion, making it ideal for boat rails, ladders, trailers, and dock structures.

Construction

Ideal for scaffolding, handrails, guardrails, building facades, and structural support beams.

Industrial & Automation

Used in robotic arms, conveyor frames, support racks, protective housings, and more.

How to Select the Right 6061 Aluminum Tube

Before choosing your 6061 tubing, consider the following:

1. Load-Bearing Needs

Heavier loads or high-stress use? Choose 6061 T9 for better fatigue performance. For general structures, T6 usually suffices.

2. Environment

If used in outdoor or marine settings, 6061’s corrosion resistance is a key advantage over steel.

3. Fabrication Method

Do you need to bend, cut, or weld the tubing? T6 offers easier machinability. Post-weld heat treatment may be required for full strength restoration.

4. Surface Appearance

6061 anodizes well, making it ideal if appearance matters. Powder coating and polishing are also common finishing methods.

Why Choose 6061 Tubing Over Other Alloys?

6061 is not the only aluminum alloy available—but it’s often the most balanced. Here’s how it compares:

| Alloy | Strength | Corrosion Resistance | Machinability | Weldability |

|---|---|---|---|---|

| 6061 | High | Excellent | Excellent | Good |

| 6063 | Moderate | Very High | Excellent | Excellent |

| 7075 | Very High | Low | Moderate | Poor |

| 2024 | High | Low | Moderate | Fair |

If you need maximum strength, 7075 may be better—but it comes with poor corrosion resistance and a higher cost. For decorative or architectural uses, 6063 may be ideal. But for all-around performance, 6061 tubing is a smart and economical choice.

Conclusion: Trust 6061 Tubing for Your Next Project

6061 aluminum tubing continues to be one of the most trusted materials in engineering and fabrication. It offers a unique mix of strength, corrosion resistance, and workability that few other metals can match.

- Need a strong and lightweight solution? Go with 6061 T6 aluminum tube.

- Need better fatigue resistance or durability under vibration? 6061 T9 aluminum tube is the answer.

- Unsure between tube and pipe? Choose tubing for structural and mechanical uses; pipe for fluid or gas transfer.

🔗 Looking for high-quality 6061 aluminum tubing?

We offer a full range of 6061 T6 aluminum tubes, 6061 T9 aluminum tubes, and custom fabrication options. Contact our team for a quote or request a stock list today.