The Growing Demand for Aluminum in Architecture

As global architecture trends shift towards sustainability, energy efficiency, and modern aesthetics, aluminum has emerged as a leading material in the construction and renovation of windows and doors. For manufacturers, developers, and contractors, understanding the benefits of aluminum in this sector is critical when choosing raw materials for high-performance building projects.

In this article, we explore the key reasons aluminum is the material of choice in the door and window industry, supported by industry trends, performance benefits, and the wide range of aluminum product forms—aluminum pipes, rods, sheets, and coils—that support these applications.

Why Aluminum is Ideal for Windows and Doors

1.1 Lightweight Yet Strong

Aluminum boasts an excellent strength-to-weight ratio. It’s significantly lighter than steel but still provides structural integrity for large window frames and sliding door systems. This makes transportation, installation, and overall handling more efficient—especially important in large-scale commercial or residential projects.

1.2 Excellent Corrosion Resistance

Unlike iron or untreated steel, aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This property is especially valuable in humid or coastal environments where metal degradation is a concern.

1.3 Slim Profiles, Larger Glass Areas

The strength of aluminum allows for slimmer frame designs, which means larger glass panes can be installed without compromising structural support. This is a key aesthetic and functional trend in modern architecture, where maximizing natural light is a top priority.

1.4 Energy Efficiency with Thermal Break Technology

Modern aluminum window and door systems can include thermal breaks—polyamide strips that reduce heat transfer through the frame. This helps meet increasingly strict building codes and energy efficiency standards across global markets.

Common Aluminum Products Used in the Door and Window Industry

To meet diverse design and performance requirements, manufacturers use several forms of aluminum raw materials:

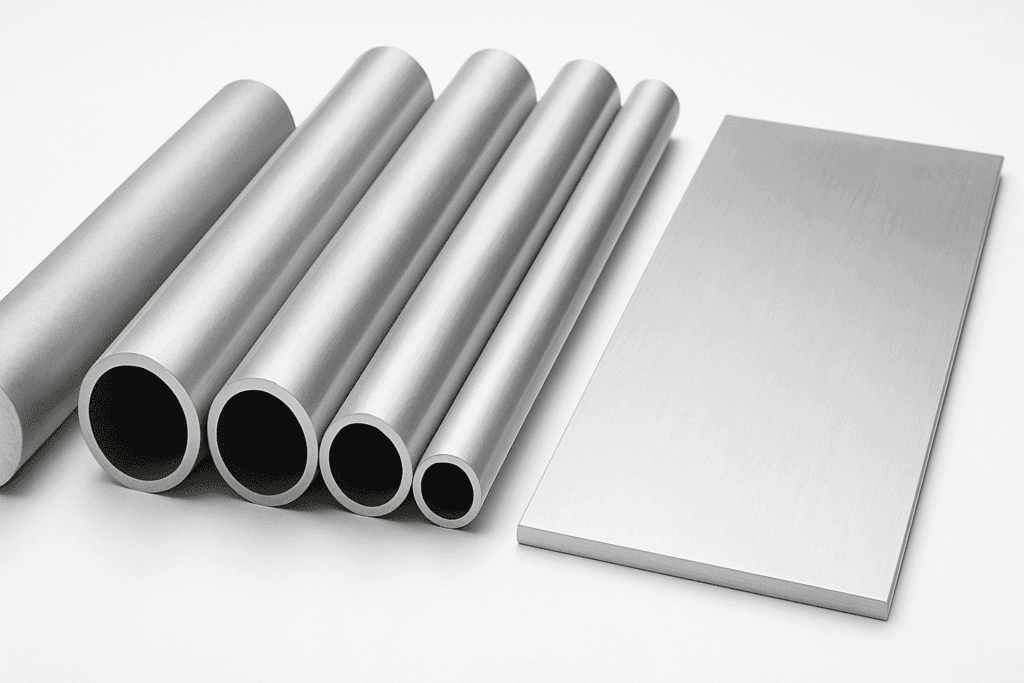

2.1 Aluminum Profiles (Extruded Rods and Tubes)

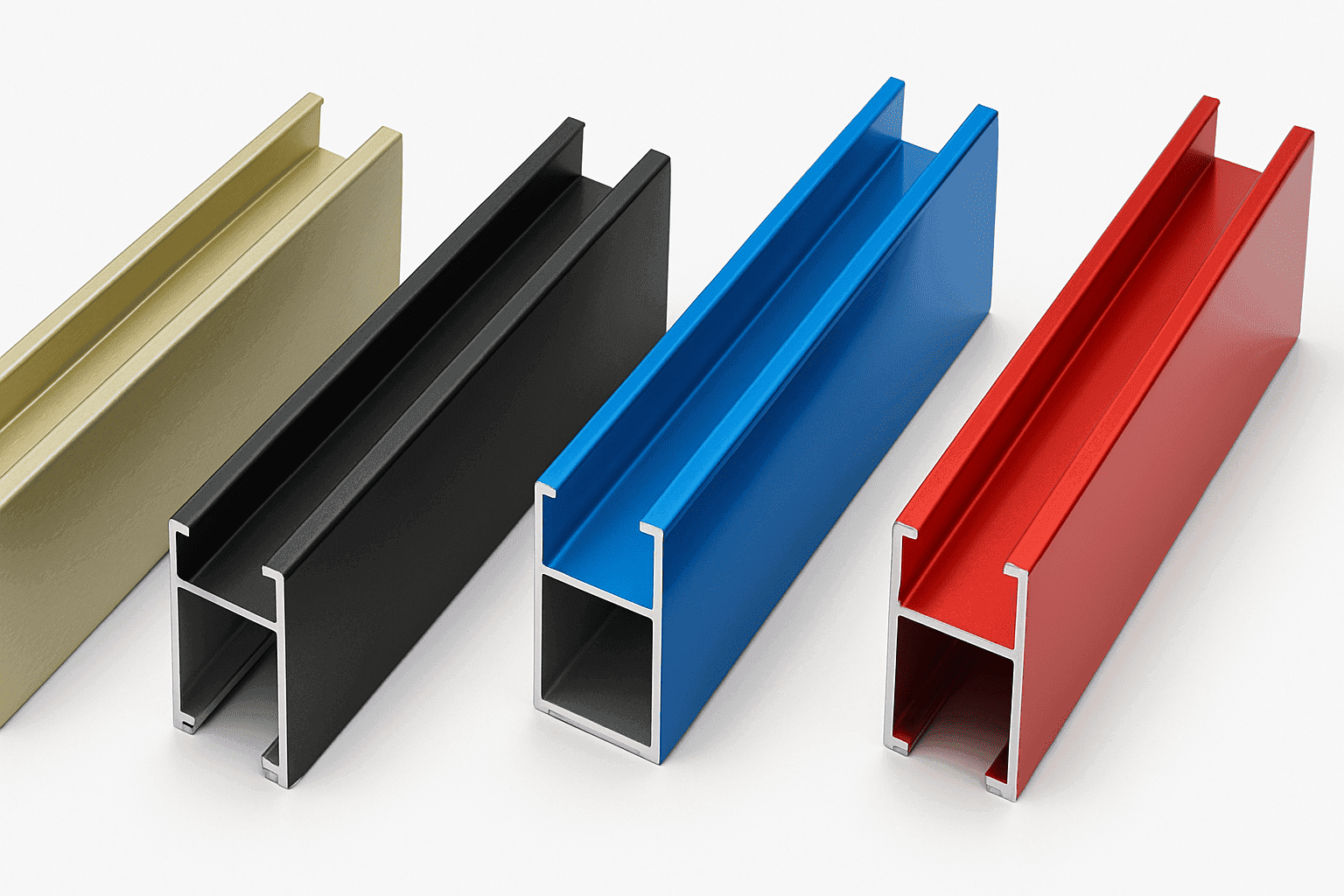

Used to create custom frames, tracks, and support structures. These profiles can be anodized or powder coated in various colors to match design specifications.

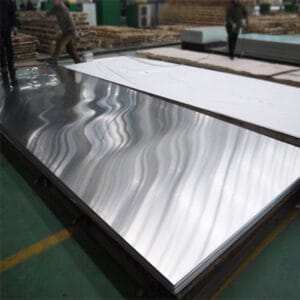

2.2 Aluminum Sheets and Plates

Ideal for panel components, cladding, and decorative trims. Sheets can be easily cut, bent, and fabricated to meet specific dimensions.

2.3 Aluminum Coils

Primarily used in rolling shutter doors or for continuous sheet production, aluminum coils offer flexibility in large-scale manufacturing.

3.Surface Finishing: Aesthetic & Functional Enhancement

Aluminum’s versatility is enhanced through various surface finishes, such as:

- Anodizing: Adds durability and color while retaining a metallic appearance.

- Powder Coating: Offers a broader color range and improved scratch resistance.

- PVDF Coating: Suitable for high-end architectural applications due to its weather and UV resistance.

These finishing processes not only enhance the appearance of aluminum but also increase longevity and reduce maintenance requirements.

4.Sustainability and Environmental Benefits

Aluminum is 100% recyclable without any loss in quality. Its reuse requires only 5% of the energy used in primary production, making it one of the most sustainable building materials available. Many green building certifications (such as LEED or BREEAM) favor materials with a strong recycling profile—boosting aluminum’s attractiveness to environmentally conscious developers.

5. Global Market Trends and Opportunities

According to industry reports, the global market for aluminum windows and doors is projected to grow steadily due to:

- Urbanization and demand for high-rise buildings

- Government initiatives on energy-efficient construction

- Rising demand for low-maintenance and long-lasting materials

Exporters of aluminum raw materials—Zhonggong offering custom profiles, coils, and treated sheets—are well-positioned to meet the growing needs of door and window manufacturers worldwide.

Conclusion: Investing in Aluminum is Investing in the Future of Construction

For businesses operating in the aluminum supply chain, understanding the role of aluminum in the door and window sector is essential for market positioning and client education. As architects and builders continue to prioritize durability, design flexibility, and sustainability, aluminum will remain a cornerstone material in the industry.