Introduction

Aluminum foil is one of the most versatile materials used in packaging, cooking, insulation, and industrial manufacturing. In this aluminum foil specifications and uses guide, we’ll explore the material’s properties, common applications, available types such as heavy duty aluminum foil, thick aluminum foil, and coloured aluminium foil, as well as key maintenance tips.

By the end of this guide, you’ll understand how to select the right foil thickness and finish for your specific needs — whether you are a manufacturer, distributor, or end-user.

What Is Aluminum Foil?

Aluminum foil is a thin sheet made primarily from pure aluminum, typically ranging from 0.005 mm to 0.2 mm in thickness. Despite its light weight, it provides an excellent barrier against light, oxygen, moisture, and bacteria — making it indispensable in many industries.

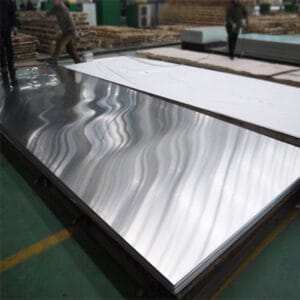

Most aluminum foil is produced from alloy series 1xxx, 3xxx, or 8xxx, each offering a balance between strength, ductility, and corrosion resistance. The manufacturing process includes rolling aluminum ingots into thin sheets, followed by annealing and surface treatment to enhance shine and flexibility.

Key Properties of Aluminum Foil

High-quality aluminum foil is defined by several physical and chemical properties that make it uniquely useful:

- Barrier performance: Blocks moisture, air, and odor effectively.

- Thermal resistance: Reflects up to 95% of radiant heat, making it perfect for insulation and baking.

- Non-toxic and food-safe: Complies with FDA and EU food contact standards.

- Lightweight yet strong: Delivers excellent packaging performance without adding bulk.

- Malleable: Can be easily shaped or laminated with other materials such as paper or plastic.

These properties vary slightly depending on the aluminum foil specifications and the alloy or temper chosen.

Aluminum Foil Specifications Explained

When sourcing aluminum foil, several technical specifications determine performance and suitability:

| Specification | Description |

|---|---|

| Alloy | Common alloys include 8011, 3003, 1235, and 1100. |

| Temper | O (soft), H18 (hard), or H22 (semi-hard) depending on use. |

| Thickness | Ranges from 0.005mm (light) to 0.2mm (heavy duty). |

| Width | Standard widths are 300mm–1600mm. |

| Surface Finish | Mill finish, embossed, or colored coatings. |

| Core Material | Aluminum, steel, or cardboard cores for industrial rolls. |

Understanding these aluminum foil specifications ensures that your chosen material meets the functional and aesthetic demands of your project.

Common Types of Aluminum Foil

1. Heavy Duty Aluminum Foil

Heavy duty aluminum foil typically has a thickness between 0.08 mm and 0.2 mm. It is designed for industrial packaging, insulation, and cooking applications requiring superior tear resistance and strength.

Applications include:

- Commercial kitchen wrapping and grilling

- HVAC duct and thermal insulation

- Cable and transformer shielding

It’s durable enough to be reused multiple times, making it a sustainable choice for both household and professional use.

2. Thick Aluminum Foil

Thick aluminum foil provides excellent rigidity and formability for heavy packaging, especially in pharmaceutical and chemical industries. It maintains its shape under stress and is ideal for forming trays, seals, and lids.

Advantages:

- Excellent puncture resistance

- High reflectivity for insulation purposes

- Compatible with embossing or lamination

3. Coloured Aluminium Foil

Coloured aluminium foil combines aesthetic appeal with functionality. It is coated with a heat-resistant, non-toxic pigment layer that enhances branding and visibility.

Common color options: gold, silver, red, blue, and black.

Typical uses:

- Decorative packaging for chocolates and confectionery

- Gift wrapping and craft materials

- Insulated bottle caps or lids

Color coatings can also offer extra UV protection, making them suitable for outdoor and display applications.

Applications of Aluminum Foil

Aluminum foil is used across multiple sectors thanks to its adaptability:

Food Packaging and Cooking

Protects freshness and flavor by preventing moisture and bacterial contamination. Common in takeaway containers, foil wraps, and baking trays.

Pharmaceutical Packaging

Used in blister packs and cold-form foils to protect tablets and capsules from light and oxygen.

Industrial Insulation

Reflective foil layers reduce heat transfer in HVAC ducts and building insulation systems.

Electronics and Energy

Applied as shielding in cables, capacitors, and battery packs to prevent electromagnetic interference (EMI).

Decorative and Printing Applications

Embossed or colored foils are ideal for product labeling, luxury packaging, and art applications.

Maintenance and Storage Tips

To preserve foil performance and appearance:

- Store rolls in a dry, dust-free area.

- Avoid direct contact with acidic or alkaline substances.

- Keep away from high humidity to prevent oxidation.

- Use soft gloves when handling colored aluminum foil to avoid fingerprints or scratches.

- Always recycle aluminum foil where facilities exist — it is 100% recyclable without loss of quality.

How to Choose the Right Aluminum Foil

- Define the application — packaging, insulation, cooking, or decoration.

- Select thickness — light, standard, or heavy duty depending on required strength.

- Choose surface finish — plain, embossed, or colored for visual impact.

- Verify specifications — confirm alloy, temper, and standards compliance (ASTM, ISO).

- Consult your supplier — reliable suppliers provide custom width, length, and surface coating options.

If you need a custom aluminum foil specification sheet, reputable manufacturers can offer tailored solutions for industrial, household, or commercial use.

Why Choose a Reliable Supplier?

Partnering with an experienced aluminum foil supplier ensures consistent quality, fast delivery, and technical support. Trusted suppliers maintain certifications such as ISO 9001, provide mill test reports, and offer export-standard packaging.

For example, manufacturers like ZGgdmetal metal provide detailed alloy designation standards and fabrication guidelines, helping buyers ensure authenticity and traceability.

Conclusion

Aluminum foil is far more than just a kitchen essential — it’s an engineering material with exceptional versatility. Understanding aluminum foil specifications and uses helps you choose the right type for each application, from heavy duty aluminum foil for industrial packaging to coloured aluminium foil for premium branding.

Whether you are designing a packaging line or selecting material for insulation systems, always verify the technical data and supplier credentials. With proper maintenance and correct specification, aluminum foil delivers outstanding performance, durability, and sustainability.