Explore how the wire drawing process transforms aluminum plates into high-performance, visually refined components across electronics, appliances, and architectural industries.

What Is the Wire Drawing Process on Aluminum Plate Surfaces?

The wire drawing process is a surface treatment technique that uses abrasives and mechanical friction to create fine, uniform lines—giving metal products a brushed, satin-like finish. Applied to aluminum plates, it serves both aesthetic and functional purposes, including:

- Concealing surface imperfections such as mold lines or machining marks

- Improving corrosion resistance when combined with anodizing

- Enhancing surface adhesion for coatings or prints

- Creating a premium, tactile finish preferred in consumer and industrial products

This process is widely used in 3C electronics, home appliances, architecture, and automotive components.

Key Benefits of Wire Drawing for Aluminum Plates

✅ Enhanced Surface Texture – Provides a uniform, decorative grain finish

✅ Defect Concealment – Masks minor scratches or manufacturing marks

✅ Improved Visual Appeal – Offers a clean, modern metallic appearance

✅ Wide Applicability – Works well with flat plates, tubes, or shaped profiles

✅ Process Customization – Multiple grain patterns and techniques available

Main Wire Drawing Techniques

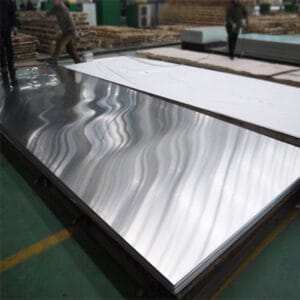

Wire drawing is typically categorized into manual and mechanical processes. For industrial applications, mechanical drawing is dominant due to its efficiency and consistency.

1. Flat Press Wire Drawing

A common method where:

- The aluminum plate is fixed on a mold

- A high-speed abrasive belt, backed by a pneumatically controlled pressure block, presses against the surface

- Produces continuous, even lines ideal for large flat surfaces

2. Roller Brush Wire Drawing

- Uses a non-woven roller brush to rotate and grind the surface

- Available in vibrating and non-vibrating modes

- Enables customization of line length and depth

- Suitable for large surface areas with curves or slight protrusions

3. Freeform (Non-Directional) Grinding

- Applies non-woven abrasive wheels or abrasive belts manually

- Best for tubular or irregular shapes (e.g., handles, decorative rods)

- Produces short, randomized lines, ideal for anti-fingerprint surfaces

Wire Drawing Texture Types

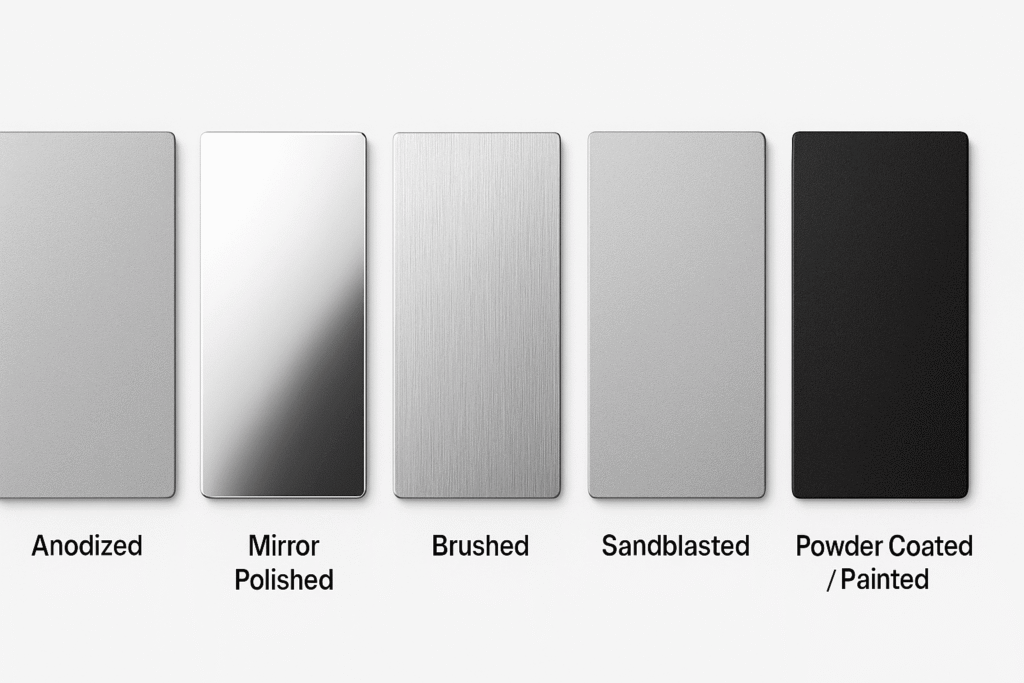

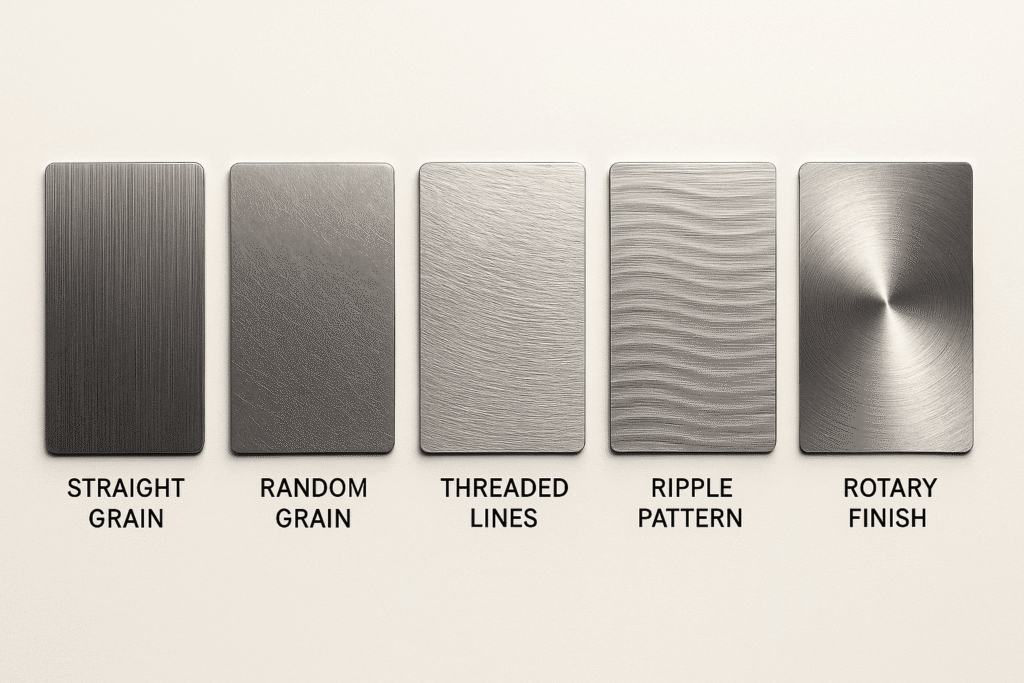

The aluminum plate’s final appearance depends on the wire drawing method and directionality. Common texture finishes include:

| Texture Type | Description |

|---|---|

| Straight Grain | Parallel lines along one direction; can be continuous or intermittent |

| Random Grain | Matte texture with non-uniform, cloudy finish |

| Threaded Lines | Fine spiral lines, often used for branding |

| Ripple Pattern | Wavy, water-like texture |

| Rotary Finish | Circular brushed pattern created by rotating felt or nylon wheels |

Typical Process Flow

- Surface Cleaning – Degreasing and removing oxide layers

- Abrasive Setup – Choose belt, brush, or wheel based on grain type

- Wire Drawing Execution – Apply mechanical brushing or rotary polishing

- Optional Coating – Anodizing or sealing for durability and corrosion resistance

- Final Inspection – Check grain uniformity, depth, and surface quality

Industrial Applications of Wire-Drawn Aluminum

Wire-drawn aluminum surfaces are widely used in:

🖥 Consumer Electronics

- Smartphone and laptop shells

- Audio equipment faceplates

- Power bank casings

🏠 Home Appliances

- Brushed aluminum panels for ovens, refrigerators

- Washing machine control panels

- Decorative appliance covers

🏢 Architectural Panels

- Interior wall claddings

- Elevator panels

- Window frames and handles

🚗 Automotive Trim

- Interior dashboard elements

- Door trims

- Gear knobs and handles

Common Questions (FAQ)

Q1: Is wire drawing the same as polishing?

A: No. Polishing creates a mirror-like finish, while wire drawing produces a textured, satin-like surface.

Q2: Can wire drawing be combined with anodizing?

A: Yes. It’s common to anodize brushed aluminum to enhance corrosion resistance and deepen the metallic look.

Q3: Will wire drawing affect aluminum thickness?

A: Minimal. The process only removes a tiny surface layer and doesn’t significantly impact dimensions.

✅ Summary: Why Choose Wire Drawing for Your Aluminum Components?

Wire drawing not only elevates the visual and tactile quality of aluminum products but also offers process flexibility for various applications and shapes. Whether for aesthetic refinement or technical preparation, it remains a critical surface treatment in modern aluminum manufacturing.

💬 Looking for high-quality wire-drawn aluminum plates?

Contact us today for technical consultation or custom surface finishing solutions.