In the world of modern manufacturing, where innovation meets efficiency, materials play a central role. Among the wide variety of metals available today, aluminum plate stands out as a remarkably versatile and high-performing option. From aerospace engineering to consumer electronics, aluminum is transforming the way products are designed and built. But what makes it such a preferred choice?

Let’s explore the reasons behind its widespread adoption — from its physical properties to its economic and environmental advantages.

1. Light Yet Strong: The Ideal Structural Balance

One of aluminum’s most significant advantages is its impressive strength-to-weight ratio. With a density roughly one-third that of steel (2.7 g/cm³), aluminum alloys like 6061-T6 and 7075-T6 offer mechanical strength that rivals or even surpasses traditional structural materials.

This lightweight durability is precisely why aluminum is indispensable in sectors like aerospace and electric vehicles. For example, aircraft manufacturers have successfully reduced weight and improved fuel efficiency by using aluminum-lithium alloys in their frames — contributing to lighter, faster, and greener aircraft.

2. Built to Last: Natural Corrosion Resistance

Another reason aluminum plate is favored in manufacturing is its innate resistance to corrosion. When exposed to air, aluminum naturally forms a thin oxide layer that acts as a shield against moisture, chemicals, and harsh environments.

This makes aluminum especially valuable in coastal or marine applications, where materials are constantly exposed to salt-laden air. Alloys like 5052 and 6061 are commonly used in shipbuilding, highway infrastructure, and outdoor structural components due to their long-lasting protection and minimal upkeep.

Real-world example: Florida’s coastal guardrails, constructed with anodized aluminum, require far less maintenance than steel equivalents — often lasting over a decade without repainting.

3. Engineered for Efficiency: Easy to Work With

Aluminum plate is highly adaptable during the fabrication process. It can be:

- Welded (TIG or MIG),

- Cut, bent, or machined with precision,

- Treated with finishes like anodizing or powder coating.

This flexibility allows manufacturers to produce complex components with ease — whether they’re crafting architectural panels or custom automotive parts. Compared to harder-to-machine metals like stainless steel, aluminum is easier and more cost-effective to manipulate.

Industry Insight: Tesla’s Model S features a full aluminum body structure, relying on aluminum plates for both strength and ease of assembly.

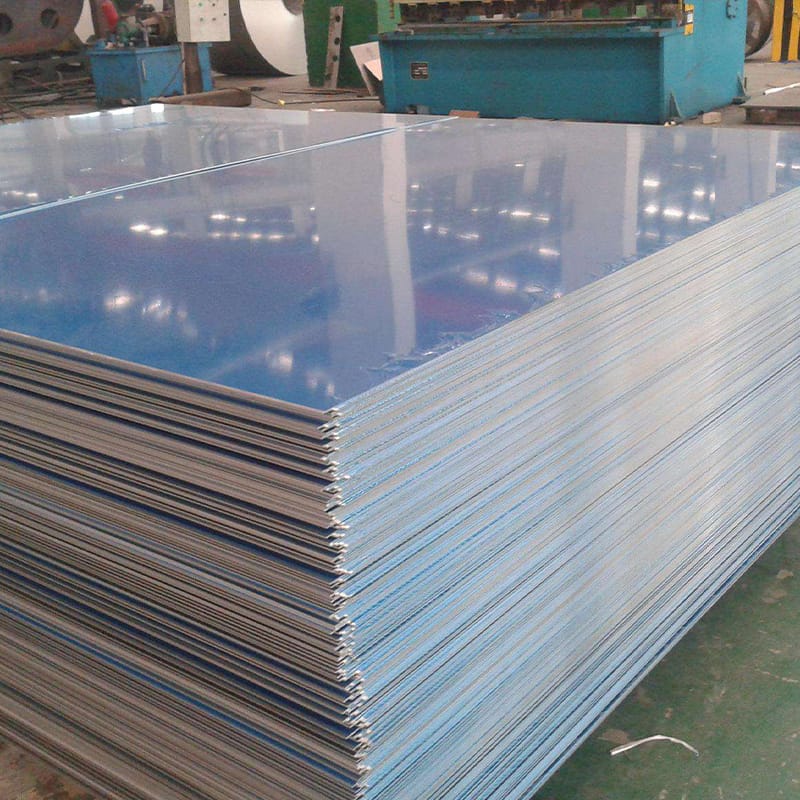

4. Tailored Alloys for Every Purpose

No two projects are the same — and that’s where aluminum’s alloy diversity shines. With a wide range of grades available, manufacturers can select the precise balance of strength, ductility, corrosion resistance, and formability they need.

| 1100 | High purity, ductile | Chemical equipment, conductors |

| 5052 | Marine-grade, bendable | Fuel tanks, signage |

| 6061 | Versatile, weldable | Frames, fixtures, aerospace |

| 7075 | High-strength, hard | Defense, aircraft structures |

5. Exceptional Thermal and Electrical Conductivity

Aluminum’s thermal conductivity is among the highest of all metals, making it ideal for use in:

- Electronic housings,

- Heat sinks,

- EV battery platforms,

- HVAC components.

It also conducts electricity efficiently — not as much as copper, but enough for many industrial applications at a lower cost and weight.

Fun Fact: Apple’s MacBook chassis is CNC-machined from a solid aluminum slab, maximizing heat dissipation and structural integrity while achieving a sleek finish.

6. A Sustainable Material for a Circular Economy

In today’s eco-conscious market, aluminum earns top marks for sustainability. It’s 100% recyclable without degradation in quality, and recycling it uses just a fraction (around 5–10%) of the energy required to produce new aluminum.

This makes aluminum an ideal choice for manufacturers looking to reduce their carbon footprint — not only is it efficient in use, but it’s also easy on the planet.

Data Point: Over 75% of aluminum ever produced is still in use today, making it one of the most efficiently recycled industrial materials.

7. Long-Term Value: Cost-Effective Over Its Lifecycle

Although aluminum may have a higher initial cost compared to standard steel, the long-term return on investment is substantial. Factors contributing to its cost-efficiency include:

- Lower maintenance needs,

- Extended service life (often over 30 years),

- No requirement for corrosion-resistant coatings,

- High residual value due to recyclability.

For industries focused on total cost of ownership (TCO), aluminum plate offers a compelling long-term advantage.

8. Widespread Applications Across Modern Industries

Aluminum plates are integral to a wide array of industries, thanks to their adaptability and performance:

| Aerospace | Wings, fuselage, internal structures | Lightweight, fatigue-resistant |

| Automotive | Body panels, battery trays | Reduces vehicle weight, boosts efficiency |

| Architecture | Cladding, framing, ceilings | Aesthetic, weatherproof, durable |

| Electronics | Housings, thermal plates | Excellent heat management |

| Packaging | Food & pharmaceutical containers | Non-toxic, moisture barrier |

Conclusion

Aluminum plate is more than just a material — it’s a strategic asset for forward-thinking manufacturers. Its unique combination of strength, light weight, corrosion resistance, machinability, and environmental benefits make it one of the most intelligent choices for both performance and sustainability.

Whether you’re developing the next generation of electric vehicles or constructing long-lasting infrastructure, aluminum offers the flexibility and reliability to get the job done — better, faster, and greener.

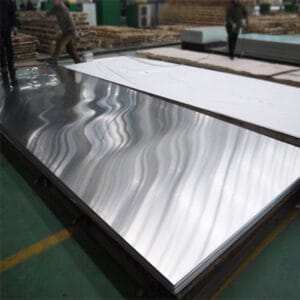

About Zggdmetal

At Zggdmetal Aluminum, we specialize in the production and global supply of high-performance aluminum plates, sheets, and custom alloy solutions. With years of experience serving industries such as aerospace, automotive, construction, and electronics, we understand the diverse and demanding requirements of modern manufacturing.

Our product range includes a wide selection of aluminum alloys—such as 1050, 5052, 6061, and 7075—available in various tempers, surface finishes, and processing options. Whether you need corrosion-resistant marine plates or high-strength structural panels, our factory is here to provide material selection guidance and customized fabrication services.

Partner with Zggdmetal Aluminum to achieve lighter, stronger, and more sustainable manufacturing results.

Contact us today to learn more about our products, get a custom quote, or request technical consultation.