Table of Contents

- What Is an Aluminum Profile?

- Common Applications of Aluminum Profiles

- Popular Types of Aluminum Profiles

- How to Cut Aluminum Profile – Step-by-Step

- Best Tools for Cutting Aluminum Profiles

- Pro Tips for Cleaner Cuts

- Frequently Asked Questions

- Get Pre-Cut or Custom Aluminum Profiles

What Is an Aluminum Profile?

An aluminum profile (also called an aluminum extrusion) is a shaped aluminum component formed by pushing aluminum through a specially designed die. The result is a continuous cross-sectional shape that’s lightweight, strong, corrosion-resistant, and easy to fabricate.

Popular alloy grades: 6061-T6 (for strength and machining), 6063-T5 (for architectural applications)

Common Applications of Aluminum Profiles

Aluminum profiles are used across industries due to their versatility and modularity:

- Construction: window frames, curtain walls, partitions

- Industrial Automation: machine enclosures, conveyor systems

- Furniture & Displays: shelf brackets, trade show booths

- Transportation: automotive components, rails

- Electronics: LED housings, heat sinks

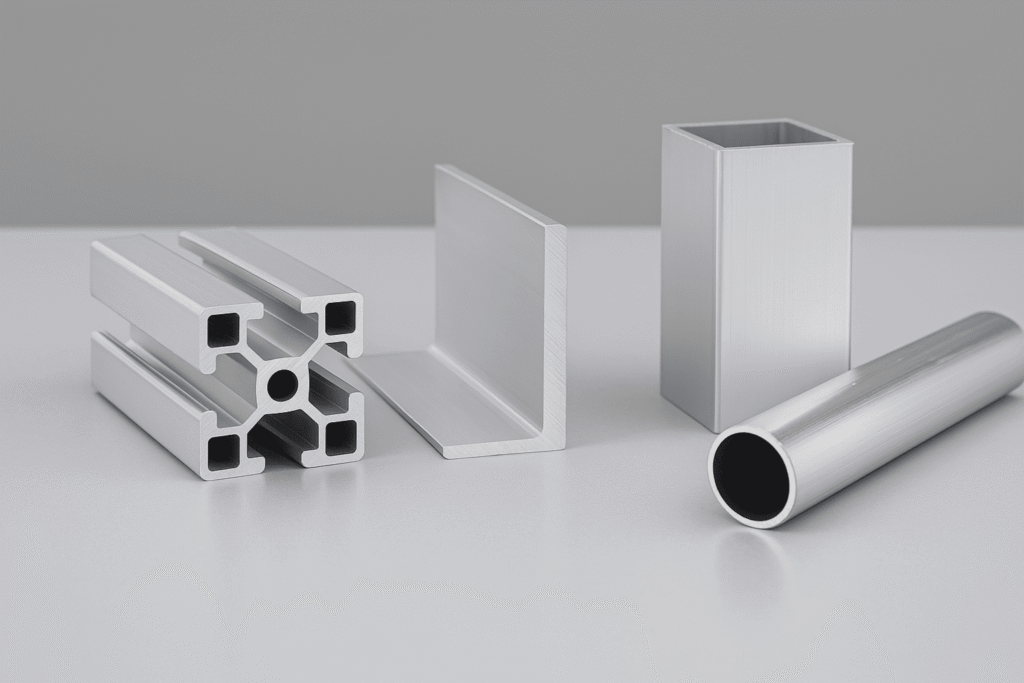

Popular Types of Aluminum Profiles

| Type | Description | Common Uses |

|---|---|---|

| T-slot (2020/4040) | Modular slots for nuts and bolts | Machine frames, 3D printers |

| L-Profile / Angle Bar | 90° angle for bracing | Furniture, framing |

| Round / Square Tubes | Hollow, strong | Structural components |

| Flat / U-Channels | Open grooves | Tracks, guides |

How to Cut Aluminum Profile

Step-by-Step Instructions

- Measure & Mark the Cut

Use a ruler and fine marker or scribe to ensure precision. Always measure twice, cut once. - Secure the Profile Firmly

Clamp it using a vise or corner bracket to avoid slippage. - Select the Right Tool

Use a carbide-tipped blade for clean cuts. For manual work, a fine-tooth hacksaw is acceptable. - Wear Proper PPE

Safety goggles, gloves, and dust mask are a must. - Cut Slowly & Smoothly

Apply steady pressure and let the blade do the work—don’t force it. - Deburr the Edges

File or sand the cut edges to remove sharp burrs for safety and fit.

Best Tools for Cutting Aluminum Profiles

| Tool | Advantages | Notes |

|---|---|---|

| Miter Saw | Fast, accurate | Use 80–100T blade for aluminum |

| Hacksaw | Simple, low-cost | Good for thin cuts |

| CNC Router | Precision cutting | Great for bulk cutting |

| Jigsaw (with metal blade) | Good for curves | Use lubricant to reduce heat |

💡 Apply cutting oil for smoother operation and less wear on the blade.

Pro Tips for Clean & Accurate Cuts

- ✅ Use a sacrificial backing board to avoid bottom edge blowout

- ✅ Clamp both the profile and the saw guide to avoid blade wandering

- ✅ Use sandpaper or a rotary deburring tool for a polished finish

- ✅ Cut in a ventilated area and clean aluminum dust immediately

Frequently Asked Questions

Q1: Can I cut aluminum profiles at home?

A: Absolutely. A miter saw with the proper blade or a hacksaw can do the job. Just follow safety precautions.

Q2: What is the best blade to use?

A: A carbide-tipped blade designed for non-ferrous metals with at least 80 teeth.

Q3: Can I cut aluminum profiles without power tools?

A: Yes, a hacksaw works, but it requires more effort and precision. Be sure to deburr afterward.

Q4: What is the safest way to cut a T-slot aluminum profile?

A: Use a compound miter saw with a clamped-down profile and wear protective gear.

Get Pre-Cut or Custom Aluminum Profiles

Looking for high-precision cuts, bulk orders, or custom anodized aluminum profiles?

👉 Contact our team for a free consultation and quick quote — we offer:

- ✅ Custom extrusion & CNC machining

- ✅ 48-hour cutting service

- ✅ Global shipping with quality assurance