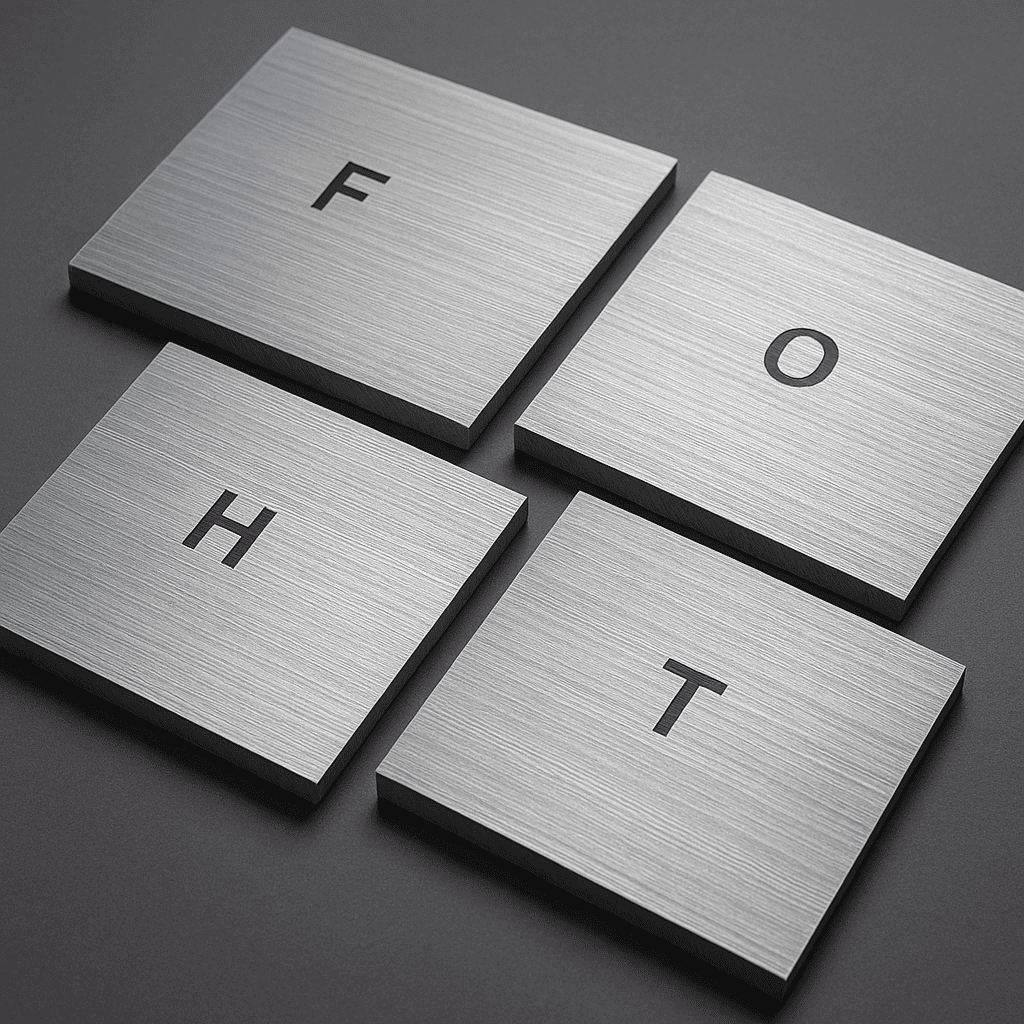

Aluminum plates are classified into five main temper states—F, O, H, T, and W—each representing a unique processing method. Choosing the correct aluminum plate temper can significantly impact mechanical strength, formability, heat resistance, and cost-efficiency.

What Are Aluminum Plate Tempers?

Tempering refers to the mechanical or thermal treatment process applied to aluminum plates to achieve specific material characteristics. Below is a detailed breakdown of each temper and how it affects performance.

1. F State — As-Fabricated Condition

Definition:

The F state (Fabricated) indicates that the aluminum plate is produced without any specific mechanical or thermal treatment. It’s typically used when post-processing is expected by the customer.

Key Characteristics:

- No defined mechanical properties

- Ideal for custom post-treatment (e.g., heat treatment or work hardening)

Use Cases:

- CNC machining parts

- Specialized engineering components

2. O State — Annealed (Soft) Condition

Definition:

The O state is fully annealed, meaning the aluminum is softened through a controlled thermal process to maximize ductility and minimize strength.

Key Benefits:

- Excellent formability

- Easy to bend, roll, and shape

- No subcategories (unlike other states)

Common Applications:

- Kitchenware

- Automotive body panels

- Aerospace forming parts

3. H State — Strain-Hardened (Cold Worked)

Definition:

The H state refers to aluminum that has undergone strain-hardening (cold working) to increase its strength without additional heat treatment.

Sub-Temper Codes:

- H1x – Strain-hardened only

- H2x – Strain-hardened, partially annealed

- H3x – Strain-hardened and stabilized

Strength Indicator:

The second digit (e.g., in H14 or H18) represents strength level, ranging from 1 (low strength) to 8 (full hard).

Ideal For:

- Roofing and facade panels

- Electrical enclosures

- Marine fittings

4. T State — Thermally Treated and Stable

Definition:

The T state indicates that the aluminum has been heat-treated to reach a stable condition after fabrication, typically to achieve maximum strength and dimensional stability.

Common Sub-Tempers:

- T5 – Cooled from shaping process and artificially aged

- T6 – Solution heat-treated and artificially aged

- T651 – T6 + stress-relief through stretching

Applications:

- Aerospace frames

- Structural components

- Heavy-duty machinery

5. W State — Solution Heat-Treated (Unstable)

Definition:

The W state is a transitional temper, meaning the aluminum plate has been solution heat-treated but is still undergoing natural aging at room temperature. It is unstable and temporary.

Important Notes:

- Rarely sold in this condition

- Mostly used internally in manufacturing processes

- Eventually transitions to T-temper if artificially aged

How to Choose the Right Aluminum Plate Temper?

| Temper | Strength | Ductility | Process | Typical Use |

|---|---|---|---|---|

| F | Varies | Varies | As-Fabricated | Custom processing |

| O | Low | High | Fully annealed | Forming, bending |

| H | Medium–High | Medium | Strain-hardened | Construction, cladding |

| T | High | Medium | Heat-treated | Aerospace, machinery |

| W | Unstable | — | Natural aging | Transition only |

🧠 Expert Tip:

If your application involves precision parts, aerospace performance, or marine corrosion resistance, always consult material engineers or certified suppliers to match the correct temper.

FAQ: Aluminum Tempering Explained

Q1: Is T6 aluminum stronger than H18?

A: Yes. T6 is heat-treated for high strength, while H18 is strain-hardened. T6 usually offers better balance between strength and machinability.

Q2: Can O-temper aluminum be anodized?

A: Yes, but since O-state is soft, the surface may be less resistant to mechanical damage compared to H or T tempers.

Q3: What is the difference between T5 and T6 aluminum?

A: T5 is cooled from a shaping process and artificially aged, while T6 undergoes full solution heat treatment and aging, resulting in higher strength.

Ready to Find the Right Aluminum Plate?

Need help choosing the best aluminum plate for your project?

👉 [Contact our materials expert now] or explore our [full aluminum product catalog].