- Introduction

- What Is an Aluminium Z Section?

- What Does the “Z of Aluminum” Refer To?

- Which Aluminium Profile Is the Strongest?

- What Grade Is Used in Aluminium Box Sections?

- conclusion

Introduction

Aluminium profiles come in various shapes and strengths, each designed for specific structural roles. Among them, the aluminium Z section stands out for its versatility in construction and framing. But what exactly is an aluminium Z section? What makes a profile strong? And which grade suits a box section application best? Let’s explore.

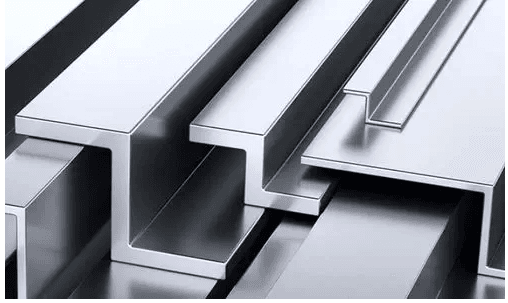

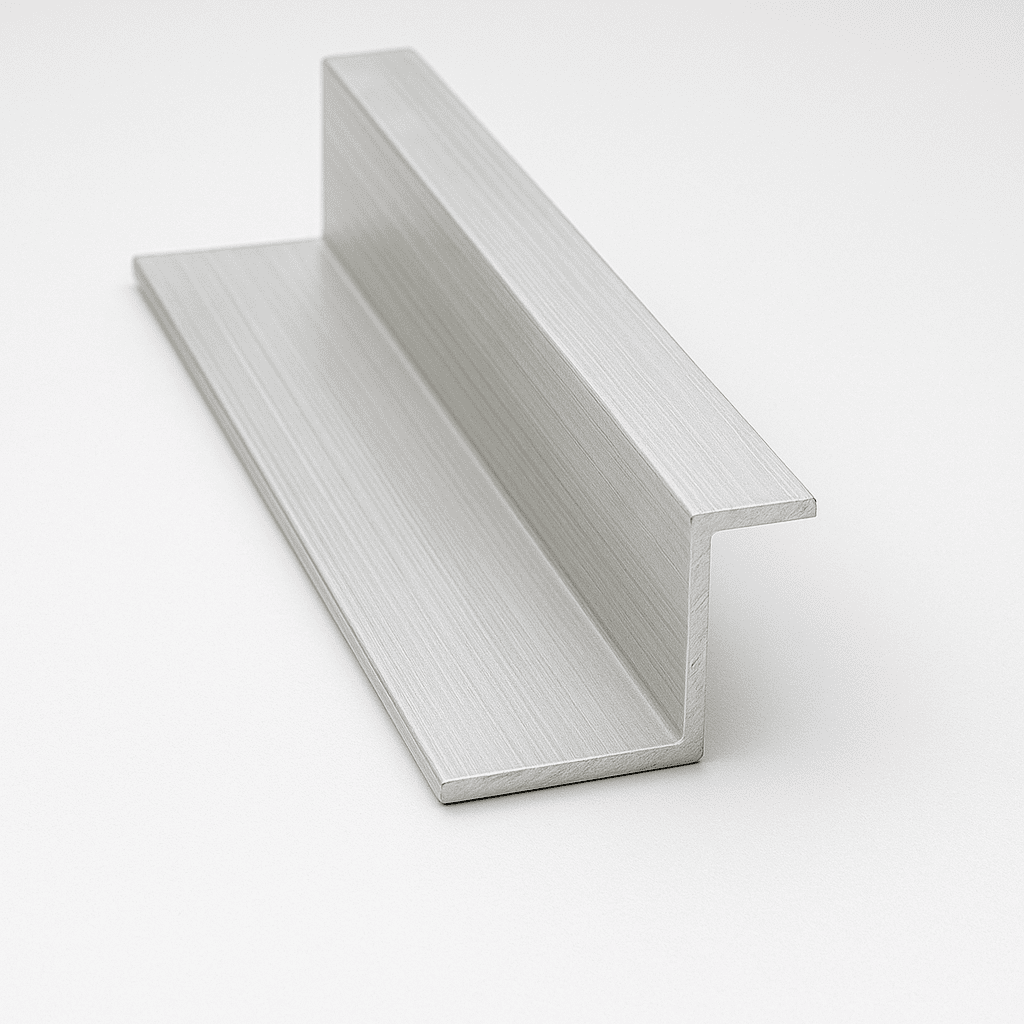

What Is an Aluminium Z Section?

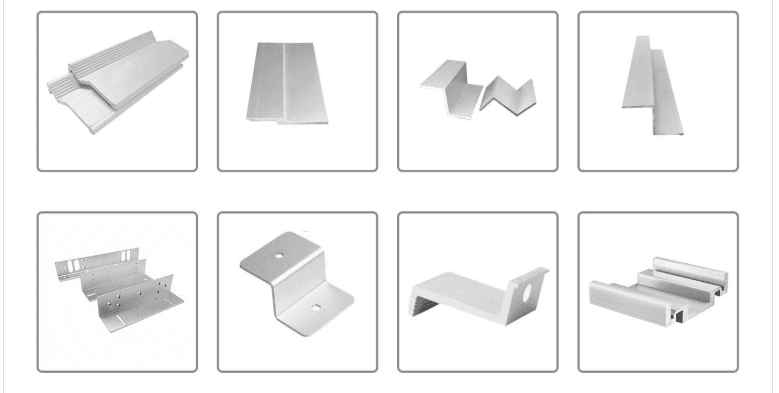

An aluminium Z section is a structural profile characterized by a Z-shaped cross-section. It’s produced through extrusion and often used where a balance between strength and weight is required. The unique Z configuration adds rigidity, making it ideal for bracing, edge framing, and support applications in both indoor and outdoor settings.

Key Benefits:

- Enhanced strength with minimal weight

- Excellent corrosion resistance in harsh environments

- Ease of fabrication: suitable for cutting, welding, and drilling

Applications Include:

- Roofing structures and wall framing

- Window and door frame reinforcements

- Transport equipment, shelving systems, and modular architecture

The geometry allows the profile to resist bending and torsion effectively, especially when used as part of larger frame systems.

What Does the “Z of Aluminum” Refer To?

In engineering contexts, when someone mentions the “Z of aluminum,” they typically refer to the Z-shaped structural profile. It’s not a material property, but rather a geometric reference. These Z-shaped profiles are engineered to optimize stiffness and directional strength, providing lateral support while keeping the structure lightweight.

Their functional design makes them especially useful in modular construction, industrial frames, and mechanical supports, where alignment and distributed load-bearing are key.

Which Aluminium Profile Is the Strongest?

The strength of an aluminium profile is influenced by two primary factors:

- Alloy Composition and Temper

- Cross-Section Design

Strongest Aluminium Alloys:

- 7075-T6 is often regarded as the strongest commercially available aluminium alloy. Commonly used in aerospace and military applications, it delivers superior tensile strength, often exceeding 500 MPa.

- 6061-T6 is another high-strength alloy with excellent machinability and weldability, widely used in structural and mechanical parts.

Strongest Profile Shapes:

Profiles following the 8020 series design, when combined with high-performance alloys like 6061 or 7075, are considered some of the most robust extrusions available.

- 8020 profiles are commonly used in industrial automation and machinery frames.

- 4040 and 2020 profiles provide lighter, less load-intensive options.

Conclusion: For maximum load capacity and structural integrity, combining a 7075-T6 alloy with an 8020-style extrusion offers the best performance.

What Grade Is Used in Aluminium Box Sections?

Aluminium box sections (square or rectangular hollow tubes) are available in a range of alloy grades depending on the intended application.

Common Grades for Box Sections:

| 6063-T6 | Smooth finish, corrosion-resistant, easy to anodize | Window frames, trims, furniture |

| 6082-T6 | High strength, good machinability | Load-bearing frames, transport systems |

| 6061-T6 | Balanced strength and weldability | Mechanical supports, frames |

| 7075-T6 | Very high strength, less weldable | Aerospace, critical mechanical parts |

For decorative or light structural uses, 6063-T6 is widely used. Where higher loads are expected, 6082-T6 is often preferred. 7075-T6 is chosen for applications that demand maximum tensile strength and fatigue resistance.

conclusion

- The aluminium Z section is a practical profile used where rigidity and lightweight construction are needed.

- The “Z of aluminum” typically refers to this structural profile, not a material property.

- The strongest aluminium profile depends on both alloy and profile design, with 7075-T6 paired with industrial profiles like 8020 being top-tier.

- For box sections, 6063, 6061, 6082, and 7075 alloys offer a range of options from decorative use to heavy-duty engineering.