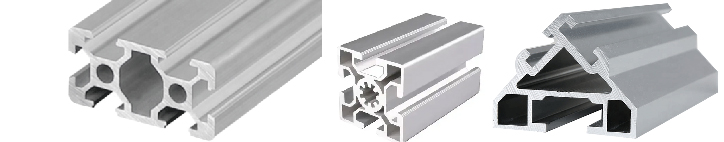

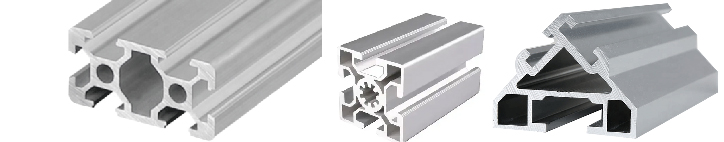

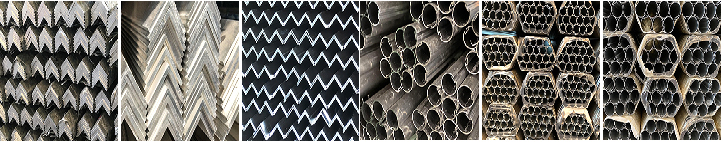

What is Aluminum L Profile?

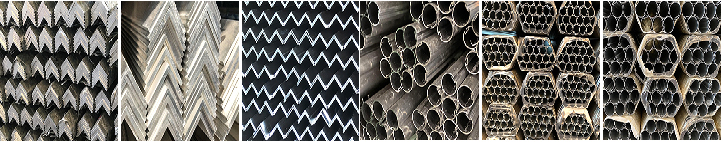

Aluminum L Profile is a type of L-shaped aluminum extrusion featuring a 90° angle, available in equal or unequal leg designs. It is widely used as a structural and decorative component in industrial, architectural, furniture, and electronic applications. Made from alloys such as 1050, 1070, 3103, 6060, and 6061, it offers excellent strength, corrosion resistance, and ease of machining. Aluminum L Profiles come in various states (O, T5, T6/T651) and sizes, typically with wing lengths from 20 mm to 130 mm, thicknesses from 0.8 mm to 5 mm, and customizable lengths. Surface treatments include anodizing (Type II/III), powder coating, and natural oxidation. They are ideal for frames, supports, edge protectors, and decorative edges, combining lightweight design with durability and versatility for multiple industrial and architectural uses.

Specifications of Aluminum L Profile

| Alloy |

1050, 1070, 3103, 6060, 6061 |

| Temper |

O , T5 , T6/T651 |

| Thickness (T) |

0.8 – 5 mm (customizable) |

| Width / Wing Length (A/B) |

20 – 130 mm |

| Length (L) |

3 – 6 m (customizable) |

| Surface Treatment |

Anodizing (Type II / III), Powder Coating, Natural Oxidation |

| Color |

Natural silver, black, white, or custom colors |

| Standard |

ASTM, JIS, GB/T standards for aluminum alloys |

| Processing & Customization |

Cutting, drilling, CNC machining, bending, welding, custom dimensions and shapes |

| Applications |

Structural supports, frames, edge protectors, decorative trims, furniture, electronics, automotive, HVAC, signage |

Stock list of Aluminum L Profile

| Alloy |

Temper |

Thickness (mm) |

Width (mm) |

Length (mm) |

Standard |

| 1050 |

O |

0.8 |

20 |

3000 |

ASTM B209 |

| 1050 |

O |

0.8 |

20 |

3000 |

GB/T 3880 |

| 1050 |

O |

0.8 |

20 |

3000 |

ASTM B209 |

| 1050 |

O |

0.8 |

20 |

3000 |

JIS H4000 |

| 1050 |

O |

0.8 |

20 |

3000 |

GB/T 3880 |

| 1050 |

O |

0.8 |

20 |

3000 |

ASTM B209 |

| 1050 |

O |

0.8 |

20 |

3000 |

JIS H4000 |

| 1050 |

O |

0.8 |

20 |

3000 |

GB/T 3880 |

| 1050 |

O |

0.8 |

20 |

3000 |

ASTM B209 |

| 1050 |

O |

0.8 |

20 |

3000 |

JIS H4000 |

👉If the standard specifications listed above do not meet your requirements, you can contact us directly to obtain customized product information. Quick Quote.

Mechanical Properties of Aluminum L Profile

| Property |

1050 Alloy (O Temper) |

| Density |

2.71g/cm³ |

| Tensile Strength (Ultimate) |

90 – 110MPa |

| Yield Strength |

35 – 50MPa |

| Elongation at Break |

28 – 35% |

| Hardness (Brinell) |

25 – 40HB |

| Modulus of Elasticity |

69GPa |

| Poisson’s Ratio |

0.33 |

| Thermal Conductivity |

217 W/m·K |

| Electrical Conductivity |

61 – 62 |

| Melting Point |

650 – 655°C |

What are Aluminum L Profile used for?

Aluminum L Profiles are versatile structural and decorative components used across a wide range of industries. They serve as supports, frames, and edge protectors in industrial equipment, machinery, and furniture. In architecture and construction, they are applied for corner trims, window and door frames, and decorative edges. They are also used in electronics for enclosures, heat sinks, and mounting structures. Due to their lightweight, corrosion resistance, and ease of machining, Aluminum L Profiles are ideal for applications in automotive parts, HVAC systems, signage, lighting fixtures, and general fabrication projects where both strength and aesthetic appeal are required.

What are the characteristics of Aluminum L Profile?

What are the characteristics of Aluminum L Profile?

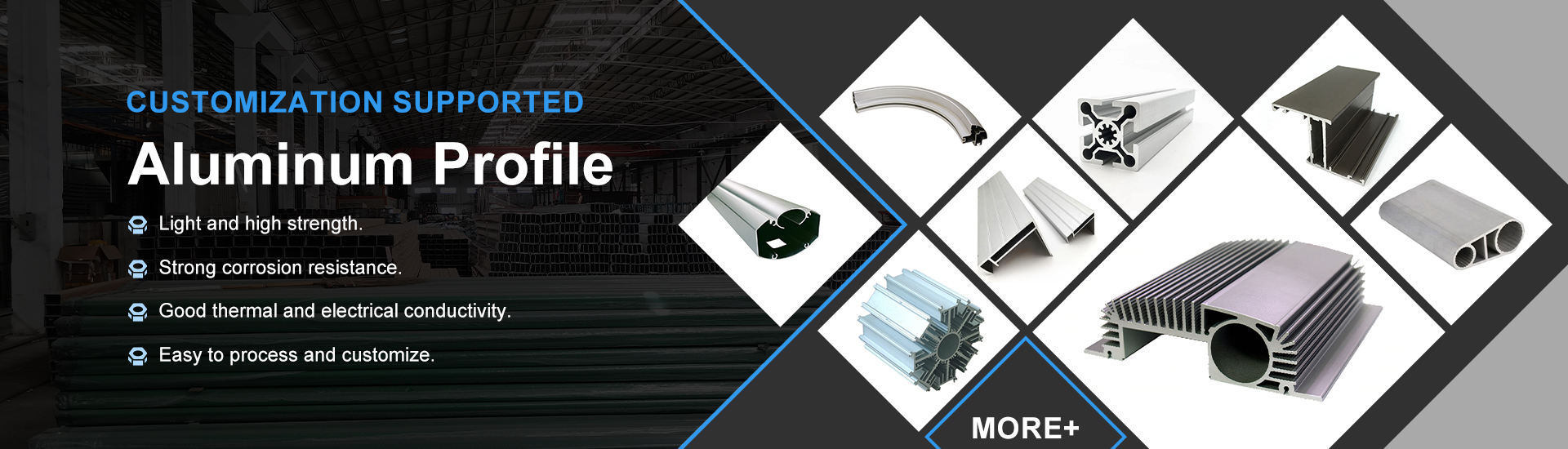

Why Choose ZGGDMETAL as Your Aluminum Profile supplier?

ZGGDMETAL is a professional manufacturer and supplier of high-quality aluminum profiles, offering extensive experience in producing L-shaped and other custom aluminum extrusions. Here’s why ZGGDMETAL stands out:

-

Premium Material Selection – We use high-grade aluminum alloys such as 1050, 1070, 3103, 6060, and 6061, ensuring excellent strength, corrosion resistance, and durability.

-

Wide Range of Profiles – From L-shaped profiles to T, U, C, Z, and H profiles, we provide a versatile selection to meet diverse industrial, architectural, and decorative needs.

-

Customizable Sizes and Finishes – We offer flexible wing lengths, thicknesses, and lengths, along with surface treatments including anodizing (Type II/III), powder coating, and natural oxidation. Colors and coatings can also be customized according to client requirements.

-

Advanced Processing Capabilities – ZGGDMETAL supports cutting, drilling, CNC machining, bending, and welding, allowing precise, ready-to-install aluminum components.

-

Compliance with Standards – All products meet international and domestic standards such as ASTM, JIS, and GB, ensuring reliable performance and quality assurance.

-

Expert Technical Support – Our experienced team provides professional guidance on alloy selection, temper, surface finish, and structural applications to help clients achieve optimal results.

Choosing ZGGDMETAL means partnering with a reliable, experienced, and customer-focused supplier dedicated to delivering high-quality aluminum profiles tailored to your project needs.