Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

Double-sided smooth aluminum foil is produced through single-rolled technology, ensuring both sides have a uniform, bright, and flat surface. Made from high-purity aluminum alloys such as 1060, 1235, 8011, or 8021, it offers excellent barrier properties against moisture, light, and gases, along with superior thermal conductivity and corrosion resistance.

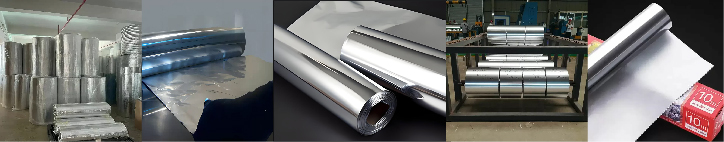

Double-sided smooth aluminum foil is a type of aluminum foil produced by a single-rolling process, which allows both sides to have an equally smooth, bright, and flat surface. Unlike standard foil made by double-rolling, which has one shiny side and one matte side, this foil offers uniform appearance and performance on both faces. It is typically made from high-purity aluminum alloys such as 1060, 1235, 8011, or 8021 and is available in thicknesses from about 0.005 mm to 0.2 mm and widths up to 1800 mm. It can be supplied in soft (O), semi-hard (H14–H28), or hard tempers to meet different processing needs. Common surface treatments include lubrication, coating, and lamination to enhance formability, heat sealing, or decorative appeal. Perfect for uses in food packaging, protecting pharmaceuticals, insulation, and industrial processes, double-sided smooth aluminum foil meets global and food safety standards, guaranteeing reliable quality, accurate thickness, and great flexibility for converting, printing, or shaping.

| Alloy | 1050 1060 2017 2024 3004 3A21 4043 5050 5050 6060 7050 8006, 8021 |

| Temper | O (Soft), H14, H16, H18, H22, H24, H26, H28 |

| Thickness | Light gauge (double zero foil): 0.005 – 0.009 mm; Medium gauge: 0.01 – 0.1 mm; Heavy gauge: 0.1 – 0.2 mm. |

| Width | 50 mm – 1800 mm(customizable); typical stock for food-grade: 200 – 1600 mm. |

| Length | 2000mm-6000mm |

| Inner Core Diameter | 76 mm (3″), 150 mm (6″) or as required |

| Roll Diameter | Typically 300 mm – 800 mm (customizable) |

| Surface Treatment | Bright on both sides; optional finishes: lubricated, coated (paint/resin), laminated with paper/plastic, embossed, anodized, printed. |

| Shape | Roll |

| Tolerances | Thickness < 0.01 mm: ± 25%; 0.01 – 0.05 mm: ± 15%; > 0.05 mm: ± 10%. |

| Standards | ASTM B479, EN 546, GB/T 3198-2010 (for food-grade 8011); ISO 9001 for quality management. |

| Payment Methods | T/T, L/C |

| Packaging | Standard export seaworthy packing: kraft paper + plastic film + wooden case or pallet |

| Applications | Food packaging, pharmaceutical blister packs, insulation materials, decorative laminates, industrial processing |

| Alloy | Thickness (µm) | Width (mm) | Tempers Available |

|---|---|---|---|

| 8011 | 11–15 (food-grade) | Up to 1600 | O (soft) |

| 3003/1060 | 5–30 | Custom | O, H14–H28 |

| Custom composite (foil + fiberglass mat) | Single-zero (~10 µm) to thicker | Up to 2000 | Soft |

| Radiant barrier rolls (insulation) | N/A (bulk material) | Consumer sizes (e.g. 48″ × 25 ft) | N/A |

👉If the standard specifications listed above do not meet your requirements, you can contact us directly to obtain customized product information. Quick Quote.

| Alloy | Temper | Tensile Strength (MPa) | Elongation (%) | Typical Thickness Range (mm) | Hardness (HV) | Notes |

|---|---|---|---|---|---|---|

| 1060 | O | 60–100 | ≥ 20 | 0.005–0.2 | 18–28 | High ductility, excellent corrosion resistance |

| 1235 | O | 60–100 | ≥ 20 | 0.005–0.2 | 18–28 | Similar to 1060, mainly for packaging foil |

| 8011 | O | 60–110 | ≥ 18 | 0.006–0.2 | 20–30 | Good formability, widely used in food/pharma |

| 8011 | H14–H18 | 110–150 | ≥ 2–5 | 0.006–0.05 | 30–50 | Higher strength, lower ductility |

| 8021 | O | 80–130 | ≥ 10 | 0.006–0.2 | 25–35 | Excellent barrier properties, used in pharma packaging |

Bright, Mirror-Like Finish on Both Sides

Excellent Barrier to Moisture, Oxygen, Light, and Contaminants

Superior Thermal and Electrical Conductivity

Food Grade, Non-Toxic, Odorless, and Recyclable

Compatible with Laminating, Coating, and Embossing Processes

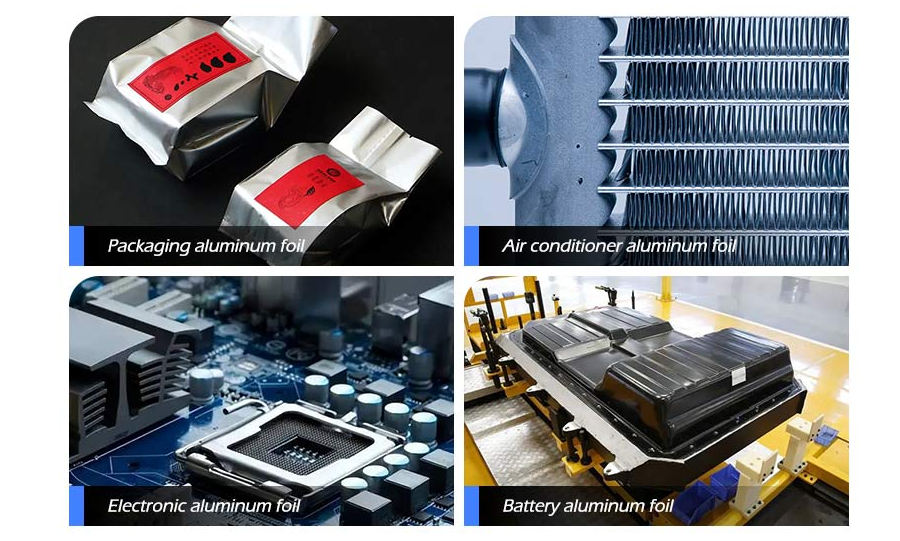

Thermal Insulation Foil – Building insulation, reflective films, HVAC

Food & Pharma Packaging – Blister foil, pouch laminates, lid stock

Decorative Use – Gift wrap, ribbon foil, label lamination

Cable & Battery Shielding – EMI shielding, lithium battery foil

Industrial Usage – Aluminum tape, composite membranes, reflective barriers

ZGGDMETAL as the largest aluminum foil supplier in china,as we have more than 15 years of experience in high-purity foil production, backed by SGS, ISO, and RoHS certifications for quality and compliance. Our full in-house processing capabilities — including slitting, annealing, coating, and printing — ensure complete control over product quality and customization. With exports to more than 60 countries and long-term OEM partnerships, we have a proven global track record. We also offer custom slitting and embossing to meet specific application needs, making us a reliable partner for tailored, high-performance aluminum foil solutions.