What is PVDF Color Coated Aluminum Coil?

PVDF Colour Coated Aluminium Coil is an aluminum sheet or strip that has been surface-coated with a high-performance Polyvinylidene Fluoride (PVDF) resin-based paint. Known for its exceptional weather resistance, UV durability, and long-lasting color retention, this material is widely used in architectural applications, such as curtain walls, roofing, cladding, and aluminum composite panels (ACP).

The coating system typically includes a primer and a PVDF topcoat, with a total thickness of ≥25μm, providing strong resistance to corrosion, pollution, and environmental aging. It is available in various alloys (e.g., 1100, 3003, 5052), tempers (e.g., H24, H26), and thicknesses (commonly 0.2mm to 1.5mm), with customizable colors according to RAL or Pantone systems.

PVDF-coated aluminum coils comply with international standards like AAMA 2605, GB/T 17748, and ISO, ensuring high-quality surface performance, flexibility, and durability in harsh outdoor environments.

Specifications of PVDF Color Coated Aluminum Coil

| Alloy |

1050, 1060, 1100, 3003, 3004, 5005, 5052, 5754, 8011 |

| Temper |

O, H12, H14, H16, H18, H24, H26, H32, H34 |

| Thickness |

0.06 mm – 1.5 mm (standard); up to 4.0 mm available on request |

| Width |

500 mm – 1600 mm (custom sizes available) |

| Length |

Coil form (continuous); Sheet length up to 6500 mm |

| Coating Type |

PVDF (Polyvinylidene Fluoride), 2 or 3-layer coating system |

| Coating Thickness |

≥25 μm (standard PVDF); up to ≥30 μm for 3-layer |

| Coating Hardness |

≥2H (Pencil hardness) |

| Weather Resistance |

≥15–20 years color durability; Salt spray resistance ≥4000 hours |

| Surface Finish |

Glossy, Matte, Embossed, Stone/Marble/Wood Grain, Brushed, Anodized look |

| Color |

RAL / Pantone custom colors available |

| Standards |

AAMA 2605, GB/T 17748, ISO, ASTM |

| Applications |

Building Facades, Curtain Walls, Roofing, Cladding, ACP Panels, Ceilings |

Stock list of PVDF Color Coated Aluminum Coil

| Coating Type |

Thickness (mm) |

Width (mm) |

Coil ID |

Alloy / Grade |

Temper (State) |

| PE |

0.10 |

1000 |

PVDF-CC001 |

1060 |

O |

| PVDF |

0.10 |

1000 |

PVDF-CC002 |

1060 |

O |

| PE |

0.10 |

1000 |

PVDF-CC003 |

1060 |

O |

| PVDF |

0.10 |

1000 |

PVDF-CC004 |

1060 |

O |

| PE |

0.10 |

1000 |

PVDF-CC005 |

1060 |

O |

| PVDF |

0.10 |

1000 |

PVDF-CC006 |

1060 |

O |

| PE |

0.10 |

1000 |

PVDF-CC007 |

1060 |

O |

| PVDF |

0.10 |

1000 |

PVDF-CC008 |

1060 |

O |

| PE |

0.10 |

1000 |

PVDF-CC009 |

1060 |

O |

| PVDF |

0.10 |

1000 |

PVDF-CC010 |

1060 |

O |

Mechanical Properties of PVDF Color Coated Aluminum Coil

Inventory information is updated in real time. Please contact us to get the latest inventory information and quotation. Quick Quote.

| Property |

Typical Value |

| Tensile Strength |

70 – 215MPa |

| Yield Strength |

30 – 160MPa |

| Elongation (A50mm) |

12% – 35% |

| Elastic Modulus |

~69,000MPa |

| Hardness (Pencil) |

≥2H (PVDF coating) |

| Coating Adhesion |

No peeling or cracking (100% adhesion) |

| Impact Resistance |

≥50kg·cm |

| T-bend Flexibility |

≤2T (no cracking on coating) |

| Salt Spray Resistance |

≥1,000 – 4,000 |

| Weather Resistance |

≥15 – 20 |

| Gloss (60°) |

10% – 90% |

👉If the standard specifications listed above do not meet your requirements, you can contact us directly to obtain customized product information. Quick Quote.

What are PVDF Color Coated Aluminum Coil used for?

What are the characteristics of PVDF Color Coated Aluminum Coil?

PVDF Colour Coated Aluminium Coil is known for its exceptional durability, superior weather resistance, and long-lasting color stability, making it ideal for demanding exterior and architectural applications.

Key Characteristics:

-

Excellent Weather Resistance

– Resists UV radiation, moisture, acid rain, and extreme temperatures for 15–20 years or more without significant fading or chalking.

-

Superior Corrosion Resistance

– The PVDF coating forms a strong barrier against salt spray, chemicals, and pollutants, making it ideal for coastal and industrial environments.

-

High Color Retention

– Maintains color vibrancy over time, with customizable shades available in RAL or Pantone systems.

-

Strong Mechanical Properties

– Good tensile strength, flexibility, and impact resistance; suitable for bending, rolling, and fabrication.

-

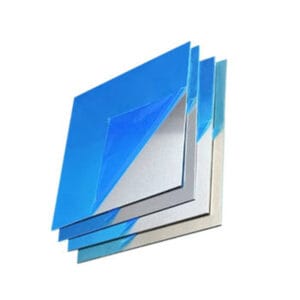

Smooth Surface & Aesthetic Appeal

– Available in glossy, matte, embossed, or textured finishes, including woodgrain and stone patterns.

-

Coating Hardness and Adhesion

– Typically ≥2H pencil hardness, with excellent adhesion (no peeling or cracking in cross-cut tests).

-

Environmentally Friendly & Low Maintenance

– Non-toxic, recyclable, and easy to clean, reducing long-term maintenance costs.

-

Standards Compliant

– Meets international quality standards such as AAMA 2605, GB/T 17748, and ISO.

These features make PVDF-coated aluminium coils a reliable and premium choice for both functional and decorative applications in architecture and industry.

Why Choose ZGGDMETAL as Your Color Coated Aluminum Coils supplier?

ZGGDMetal offers a wide range of advanced surface treatments for aluminium coils and sheets to meet diverse architectural and industrial needs. These treatments enhance corrosion resistance, aesthetic appearance, and coating durability.

Available Surface Treatments:

-

PVDF Coating (Polyvinylidene Fluoride)

– High-performance fluorocarbon finish with outstanding UV resistance, color stability, and long-term weather durability. Ideal for exterior applications.

-

PE Coating (Polyester)

– Economical coating with good gloss and color range, suitable for interior or light exterior use.

-

Embossed Finish

– Adds texture for decorative effects or anti-slip functions; commonly used in panels, ceilings, and packaging.

-

Wood Grain / Stone Grain Transfer Coating

– Simulates natural textures while maintaining aluminium’s lightweight and corrosion resistance; widely used in cladding and decoration.

-

Brushed / Anodized Appearance

– Provides a modern, metallic matte effect; available as part of coated finishes to mimic brushed aluminium.

-

High Gloss / Matte Finish

– Gloss level customizable from 10%–90%, depending on design needs.

-

Customized Color Coating

– Full RAL and Pantone color matching available for branding and architectural integration.

ZGGDMetal’s surface treatments combine technical performance with design flexibility, making them suitable for facades, roofing, signage, ceilings, and composite panels.