What is Aluminum Round Plate?

Aluminum round plates are cut into round shapes using lasers or molds. They have a smooth, flat surface, free of oil stains, scratches, and other defects.The thickness range of aluminum round plate is ≥1/4″ (about 6mm), and thinner ones are named aluminum round circle.They are suitable for deep drawing, spinning, and other processing techniques and are widely used in cookware manufacturing, lighting, and other fields. Commonly used standards include:ASTM B209, AMS-QQ-A-250/11, EN 485, and GB/T 3880.

Specifications of ZGGDMETAL aluminum round plate

| Alloy & Temper |

1060 (O/H14/H18/H24), 1100, 3003-H14, 5052-H32, 6061-T6/T651 |

| Diameter |

100 mm – 600 mm (4″–24″), custom sizes available |

| Thickness |

0.3 mm – 6.0 mm (coil-based), 0.8 mm – 9.5 mm (circle blanks), up to several inches available |

| Surface Finish |

Mill finish, anodized, brushed, PVC-coated, polished, painted, or powder-coated |

| Standards |

ASTM B209, AMS-QQ-A-250/11, EN 485-2 / EN 573-3, GB/T 3880-2006 |

| Processing Types |

Laser cutting, CNC blanking, stamping, spinning, deep drawing, anodizing |

| Packaging |

Standard export package: wooden pallet + plastic film + protective paper; optional custom boxes |

| Payment Terms |

T/T (30% deposit, 70% balance before shipment), L/C at sight, PayPal |

| Applications |

Cookware, lighting housings, traffic signs, pressure cookers, electronic casings, nameplates |

Stock of ZGGDMETAL Aluminum Round Plate

| Diameter (mm) |

Diameter (inch) |

Available Thickness (mm) |

Available Thickness (inch) |

| 100 – 150 |

4″ – 6″ |

0.3 / 0.5 / 1.0 / 1.5 / 2.0 / 3.0 |

0.012″ / 0.02″ / 0.04″ – 0.12″ |

| 200 – 300 |

8″ – 12″ |

1.0 / 1.5 / 2.0 / 3.0 / 4.0 / 5.0 |

0.04″ – 0.2″ |

| 350 – 400 |

14″ – 16″ |

2.0 / 3.0 / 4.0 / 5.0 / 6.0 |

0.08″ – 0.24″ |

| 450 – 500 |

18″ – 20″ |

3.0 / 4.0 / 5.0 / 6.0 / 8.0 |

0.12″ – 0.31″ |

| 550 – 600 |

22″ – 24″ |

4.0 / 5.0 / 6.0 / 8.0 / 10.0 |

0.16″ – 0.39″ |

| Custom sizes |

Any |

Up to 100 mm (4″) or by request |

Up to 4″ |

Inventory information is updated in real time. Please contact us to get the latest inventory information and quotation.

Quick Quote.

Standard of ZGGDMETAL aluminum round plate

| Standard Code |

Issuing Body |

Applicable Scope |

| ASTM B209 |

ASTM International |

Standard specification for aluminum and aluminum-alloy sheet and plate |

| AMS-QQ-A-250/11 |

SAE (Aerospace Material Specification) |

Covers aluminum alloy plate and sheet for aerospace and general use |

| EN 485-2 / EN 573-3 |

European Committee for Standardization (CEN) |

Specifies mechanical properties and chemical composition for wrought aluminum sheets and plates |

| GB/T 3880-2006 |

Standardization Administration of China (SAC) |

National standard for aluminum and aluminum alloy plates, sheets, and strips |

What states and alloy types of aluminum round plates can ZGGDMETAL provide?

- Common alloys: 1100, 3003-H14, 5052-H32, 6061-T6/T651, etc.

- Common tempers include:

- 3003-H14 (cold work-hardened state, offering good machinability)

- 1060 tempers such as O, H14, H18, and H24, each with varying plasticity and strength

- 6061-T6 or T651 (heat-treated hardened state, providing high strength and stability)

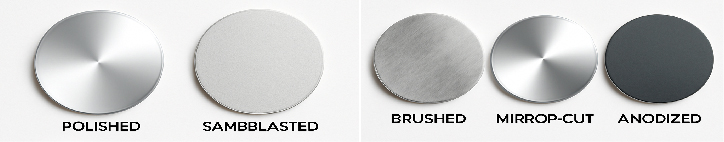

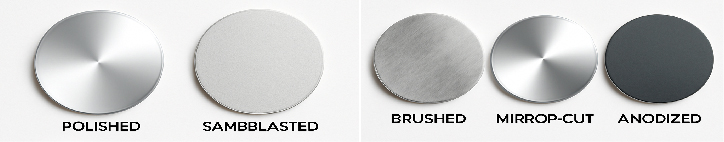

What surface treatments can ZGGDMETAL provide?

| Surface Treatment |

Description |

Typical Applications |

| Mill Finish |

Smooth surface in its natural state, unpolished and untreated |

General machining, forming, industrial applications |

| Anodized |

Electrochemical process that enhances corrosion resistance and allows for coloring |

Architectural panels, electronics, consumer goods |

| Brushed Finish |

Mechanical surface treatment that creates a linear texture |

Decorative trims, appliances, lighting |

| Polished |

Surface is buffed to a mirror-like finish |

Reflectors, signage, high-end cookware |

| PVC Film Coated |

Protective film applied to prevent scratches during handling and shipping |

Export packaging, surface-sensitive components |

| Coated / Painted |

Organic or metallic coating applied via spray or roll coating |

Traffic signs, decorative parts, outdoor panels |

| Custom Surface Treatment |

Includes powder coating, plating, etching, laser marking, etc., upon request |

OEM parts, branded products, high-spec applications |

ZGGDMETAL Aluminum Round Plate Applications

- Cookware & Bakeware

Widely used for pots, pans, pizza trays, pie plates, lids, and electric cookware — prized for high thermal conductivity and excellent formability.

- Lighting & Signage

Used in lampshades, reflectors, traffic signs, and architectural lighting fixtures. Alloys like 1100 offer deep drawing quality and high reflectivity (≥ 65%).

- Machinery, Tooling & Structural Components

6061 alloy circles serve in machinery parts, tooling plates, structural components, bridge railings, and industrial assemblies. Formed via cutting and machining for precision tools and fixtures.

- Industrial & Pressure Vessels

Used as end caps or cover plates in pressure vessels and tanks (8011). Also as mount plates, spacer blanks, and assembly jigs in various industrial applications.

- Precision Machining, Fixtures & Accessories

Machinists employ discs as backer plates, fixture adapters, bearing spacers, jigs, and tooling aids due to lightweight and machinability.

- Electronics, Appliance & Consumer Goods

6061 aluminum round circle are used in electronic housings, heating elements, automotive parts, daily chemical containers, and medical device components — known for strength, weldability, and corrosion resistance.

What should I consider when purchasing aluminum round plates?

In industrial manufacturing, precision machining, or deep-processing, selecting the right aluminum round plates is crucial for ensuring product quality and process stability. The following are key technical considerations during the procurement process:

1. Clarify the end-use application and processing requirements.

Different applications have different requirements for the physical properties, dimensional accuracy, and surface quality of aluminum round plates:

- For deep drawing or spinning: Prioritize alloys with excellent ductility, such as 1100-O and 3003-H14.

- For structural and machined parts: Choose alloys with high strength and stability, such as 6061-T6/T651.

- For decorative applications: Surface treatment and corrosion resistance are more important, and anodizing or brushing is recommended.

2. Alloy Grade Selection Criteria

- 1100 Series: Pure aluminum with strong conductivity and corrosion resistance, suitable for deep drawing and lightweight structural parts.

- 3003 Series: With the addition of manganese, the strength is slightly higher than 1100, and it combines good ductility and corrosion resistance, making it suitable for kitchenware, lamp chassis, pressure vessels, etc.

- 6061 Series: A typical heat-treatable alloy, offering high strength, good weldability, and corrosion resistance, making it suitable for load-bearing structures and precision machining.

3. Heat Treatment Condition (Temper) Selection

The strength, workability, and residual stress control of aluminum round plates are closely related to their heat treatment condition:

- O Temper (Annealed Temper): Soft, suitable for high-deformation spinning and deep drawing.

- H14/H24: Medium strength, suitable for some plastic working.

- T6/T651: Artificially aged, providing higher strength and dimensional stability, suitable for structural parts and precision machining.

4. Dimensional Specifications and Processing Tolerances

Confirm the required outer diameter (OD), thickness, and flatness requirements, and discuss these with the supplier:

- Is fine grinding, leveling, or deburring required?

- Does the tolerance meet standards such as ASTM B209 and EN 485?

- Is custom-made molds or custom molds supported?

5. Surface Treatment and Cleanliness Level

Consider the need for surface treatment based on the intended use:

- Anodizing: Improves corrosion resistance and surface hardness;

- Brushed/mirror polish: Used for decorative purposes, lighting, kitchen appliances, etc.;

- Laminating or painting: Enhances scratch resistance and is suitable for products with high aesthetic requirements.

6. Stock Availability and Customization Capabilities

For large-volume or non-standard specifications, we recommend prioritizing the following information:

- Availability of standard diameters (e.g., ∅100mm–∅1000mm) and thicknesses (0.5–6mm);

- Whether the supplier has mold development, batch cutting, and secondary processing capabilities;

- Whether third-party quality inspection reports (e.g., SGS, BV) and material certification (MTC) are available.