Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

Aluminum disk is a precision blanking material made from aluminum coils by stamping or deep drawing. It is widely used in cookware manufacturing, lighting, traffic signs, and industrial parts due to its excellent formability, lightweight, and corrosion resistance.

Aluminum disks are ideal for applications requiring deep drawing or spinning. The product features smooth surfaces, burr-free edges, uniform thickness, and high thermal conductivity, making it the preferred raw material in multiple manufacturing fields.

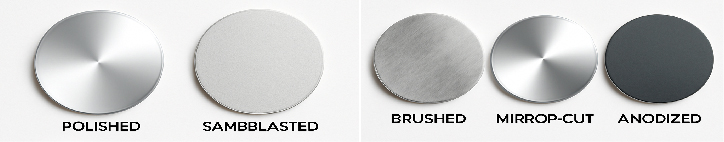

An aluminum disk is a flat, round alloy raw material produced by cutting or punching aluminum alloy plates. Due to its excellent formability, lightweight, corrosion resistance, and thermal conductivity, it is commonly used in industries such as cookware, lighting, road signs, and automotive parts. Common aluminum disk alloy grades include 1050, 1060, 3003, and 5052, and tempers include O, H14, and H24. Its smooth surface and uniform thickness make it ideal for deep drawing, spinning, and surface treatments such as polishing, anodizing, or coating. Aluminum disk is a key raw material for the manufacture of frying pans, pressure cookers, lampshade reflectors, traffic signs, and other shaped aluminum products.

| Alloy | 1050,1060,1070,1100,3003,5052 |

| Temper | O,H12, H14, H18, H24,H32,H34 |

| Diameter | 100mm-1200mm (customizable up to 1500 mm) |

| Thickness | 0.4mm-6.0mm |

| Surface | Mill finish, anodized,polished |

| Standards | ASTM B209 ,EN 573 / EN 485 ,GB/T 3880 ,ISO 9001 / ISO 14001 |

| Processing Types | Blanking,Stamping,Deep Drawing,Spinning,CNC Cutting |

| Packaging | Export-worthy wooden pallets or wooden cases with plastic film and corner protection |

| Payment Terms | T/T,L/C, Western Union, PayPal |

| Applications | Cookware (pans, pots, kettles), Lighting Fixtures, Road Signs, Pressure Vessels, Decorative Parts, Electrical Appliances |

| Diameter (mm) | Diameter (in) | Thickness (mm) | Thickness (in) | |

|---|---|---|---|---|

| Ø 100 mm × 0.8 mm | 100 mm | 3.94″ | 0.6 / 0.8 / 1.0 | 0.024 / 0.031 / 0.039″ |

| Ø 150 mm × 1.2 mm | 150 mm | 5.91″ | 0.8 / 1.0 / 1.2 / 1.5 | 0.031 / 0.039 / 0.047 / 0.059″ |

| Ø 200 mm x1.0 mm | 200 mm | 7.87″ | 1.0 / 1.2 / 1.5 / 2.0 | 0.039 / 0.047 / 0.059 / 0.079″ |

| Ø250 mm x1.5mm | 250 mm | 9.84″ | 1.2 / 1.5 / 2.0 / 2.5 | 0.047 / 0.059 / 0.079 / 0.098″ |

| Ø300 mm x2.0mm | 300 mm | 11.81″ | 1.5 / 2.0 / 2.5 / 3.0 | 0.059 / 0.079 / 0.098 / 0.118″ |

| Ø350 mm x2.0mm | 350 mm | 13.78″ | 1.5 / 2.0 / 2.5 / 3.0 | 0.059 / 0.079 / 0.098 / 0.118″ |

| Ø400 mm x1.5mm | 400 mm | 15.75″ | 2.0 / 2.5 / 3.0 / 4.0 | 0.079 / 0.098 / 0.118 / 0.157″ |

| Ø450 mm x3.0mm | 450 mm | 17.72″ | 2.0 / 2.5 / 3.0 / 4.0 | 0.079 / 0.098 / 0.118 / 0.157″ |

| Ø500 mm x3.0mm | 500 mm | 19.69″ | 2.0 / 2.5 / 3.0 / 5.0 | 0.079 / 0.098 / 0.118 / 0.197″ |

| Ø600 mm x4.0mm | 600 mm | 23.62″ | 2.5 / 3.0 / 4.0 / 5.0 | 0.098 / 0.118 / 0.157 / 0.197″ |

| Ø800 mm x5.0mm | 800 mm | 31.50″ | 3.0 / 4.0 / 5.0 / 6.0 | 0.118 / 0.157 / 0.197 / 0.236″ |

| Ø1000 mm x5.0mm | 1000 mm | 39.37″ | 3.0 / 4.0 / 5.0 / 6.0 | 0.118 / 0.157 / 0.197 / 0.236″ |

| Ø1200 mm x6.0mm | 1200 mm | 47.24″ | 4.0 / 5.0 / 6.0 | 0.157 / 0.197 / 0.236″ |

| Standard Code | Region | Description |

|---|---|---|

| ASTM B209 | USA | Aluminum and Aluminum-Alloy Sheet and Plate Standard |

| EN 573 / EN 485 | Europe | Chemical composition and mechanical properties |

| GB/T 3880 | China | National standards for aluminum rolled products |

| ISO 9001 / 14001 | International | Quality and environmental management systems |

| RoHS / REACH | EU | Compliance for environmental safety regulations |

| Surface Type | Description |

|---|---|

| Mill Finish | Natural aluminum surface, smooth, silver-white |

| Polished | Mechanically or chemically brightened for aesthetic use (cookware, lighting) |

| Anodized | Electrochemical oxidation for corrosion resistance and color enhancement |

| Brushed | Fine directional grain for decorative uses |

| Coated / Painted | For specific industrial applications or branding needs |

| Oil-coated | To prevent oxidation during storage and transit |