What is Aluminum Circle Blanks?

Aluminum circle blanks are flat, circular pieces cut or stamped from aluminum sheets or coils. They serve as raw material for manufacturing products that require deep drawing, spinning, or precise shaping.

Thanks to their light weight, excellent thermal conductivity, and corrosion resistance, aluminum circle blanks are widely used in cookware, lighting fixtures, decorative spinning components, and signage. They are available in different alloys (such as 1060, 3003, 5052, 6061), tempers (O, H14, H24, etc.), and surface finishes (mill finish, anodized, alodized) to meet specific application needs.

In short, aluminum circle blanks are a versatile intermediate product designed for high-precision manufacturing across various industries.

Specifications of Aluminum Circle Blanks

| Alloy |

1060、1070、3003、5052、6061 |

| Temper |

O、H14、H24、H32、T4、T6 |

| Diameter |

0.3mm~4mm(0.118“~0.157”) |

| Thickness |

100mm~980mm(3.9″~38.5″) |

| Surface Finish |

Smooth, oil-free, scratch-free, anodized, |

| Standards |

ASTM B209, AMS‑QQ‑A‑250/11, EN 485, GB/T 3880, ASTM B499, MIL‑A‑8625 |

| Packaging |

Standard export package: wooden pallet + plastic film + protective paper |

| Payment Terms |

T/T , L/C , PayPal |

| Applications |

Cookware, Kitchenware,Lighting, Reflectors, Traffic, Signage, Automotive, Transportation, Electronics, Electrical Applications, Aerospace, Aviation |

Stock of Aluminum Circle Blanks

| Alloy |

Temper |

Thickness(mm/inch) |

Diameter(mm) |

| 1050 / 1060 / 1070 |

O, H14, H24 |

0.8(0.032″) – 4.0(0.157″) |

100 (4″), 152(6″),

203(8″), 254(10″),

305(12″), up to

980(38.5″) |

| 1100 |

O, H14 |

0.8(0.032″) – 3.0(0.118″) |

100(4″)-

800(31.5″) |

| 3003 |

O, H14, H24 |

0.8(0.032″) – 4.0(0.157″) |

100(4″), 152(6″),

203(8″), 254(10″),

305(12″), up to

980(38.5″) |

| 5052 |

O, H32, H34 |

1.0(0.039″)–5.0 (0.197″) |

100(4″)-

980(38.5″) |

| 6061 |

T4, T6 |

1.0(0.039″) – 6.0 (0.236) |

150(6″), 203(8″),

254(10″), up to

600(23.6″) |

Get the latest inventory information if you need to purchase or customize.Quick Quote

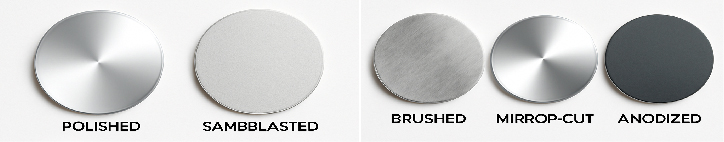

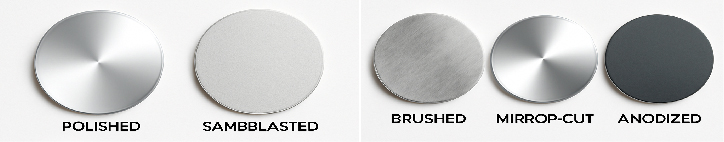

What surface treatments of aluminum circle blanks can ZGGDMETAL provide?

- Anodizing: Improves corrosion and wear resistance and can be dyed or cleared. According to MIL-A-8625, it is classified as follows:

- Type I (chromic acid): Thin films 0.5–18µm, used for pre-coating or decoration;

- Type II (sulfuric acid): Medium-thick films 1.8–25µm;

- Type III (hard anodizing): Thick films >25µm (13–150µm), used in heavy-duty abrasion environments.

- Chemical pretreatment/colloidal coating: For example, treatment according to ASTM B499 (“alodizing”) is commonly used for road sign discs, providing excellent adhesion and durability.

- Smooth and bright finish: Typically used for deep drawing or spinning, the surface is free of oil, dirt, and scratches, making it easy to process or anodize.

What are the characteristics of aluminum circle blanks?

Aluminum circle blanks are flat, circular discs cut or stamped from aluminum sheets or coils. Their key characteristics include:

-

Lightweight yet strong – Aluminum’s low density reduces weight without compromising structural integrity, making handling and transportation easier.

-

Excellent formability – Available in various tempers (O, H14, H24, T4, T6), they can be deep drawn, spun, or stamped into complex shapes without cracking.

-

Smooth and uniform surface – Blanks are supplied with mill finish, brushed, or anodized surfaces, ensuring consistent quality for further processing like painting or anodizing.

-

Outstanding corrosion resistance – Naturally resistant to rust, with enhanced durability when anodized, coated, or chemically treated.

-

Good thermal conductivity – Ideal for cookware, lighting, and heat-dissipating parts due to efficient heat transfer.

-

High reflectivity – Especially when polished or anodized, making them suitable for lighting reflectors and decorative applications.

-

Wide range of specifications – Produced in different alloys (1060, 3003, 5052, 6061, etc.), diameters (100–980 mm / 4″–38.5″), and thicknesses (0.3–6.0 mm) to meet diverse needs.

-

Eco-friendly and recyclable – 100% recyclable without loss of properties, supporting sustainable manufacturing.

What are aluminum circle blanks used for?

Cookware & Kitchenware

Widely used to manufacture frying pans, pots, baking trays, pressure cookers, and lids, thanks to their excellent thermal conductivity, lightweight nature, and corrosion resistance. They support uniform heat distribution and are easy to handle and clean.

Lighting & Reflectors

Employed in producing lamp reflectors, shades, and fixtures. Their smooth surface and high reflectivity, often enhanced via anodizing, make them ideal for directing light efficiently.

Traffic & Signage

Used for road signs, traffic indicators, and commercial signage due to their durability, ability to withstand harsh weather, and ease of printing or coating.

Automotive & Transportation

Applied in manufacturing lightweight automotive parts like decorative trims, hubcaps, rims, engine components, and fuel covers—helping to improve fuel efficiency while maintaining strength.

Electronics & Electrical Applications

Used for heat sinks, capacitor housings, baseplates in refrigeration compressors, and other thermal management or electrical parts thanks to their thermal and electrical conductivity.

Aerospace & Aviation

Suitable for components such as fuselage panels, wing ribs, and structural reinforcement—valued for their high strength-to-weight ratio and anti-corrosive nature.

Packaging, Containers & Consumer Goods

Used in making lids, seals, and parts for food and beverage packaging, pharmaceutical containers, and household items. Aluminum’s non-toxicity and corrosion resistance contribute to long-term use.

Construction, Architectural & Decorative Use

Utilized in architectural panels, decorative cladding, ceiling tiles, access covers, water heater shells, and other design elements that benefit from its durability, lightweight, and aesthetics.

Industrial Machinery & Equipment

Employed as blank material for stamping, machining, and custom tooling; blanks serve for gaskets, seals, and various industrial components.