What is Aluminum C Profile?

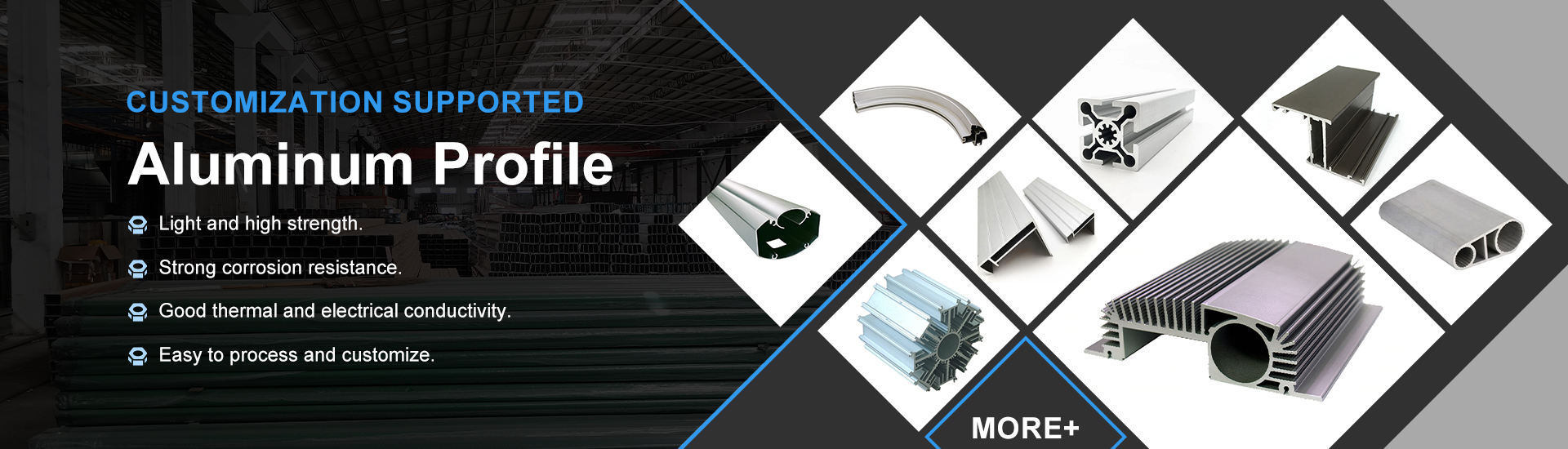

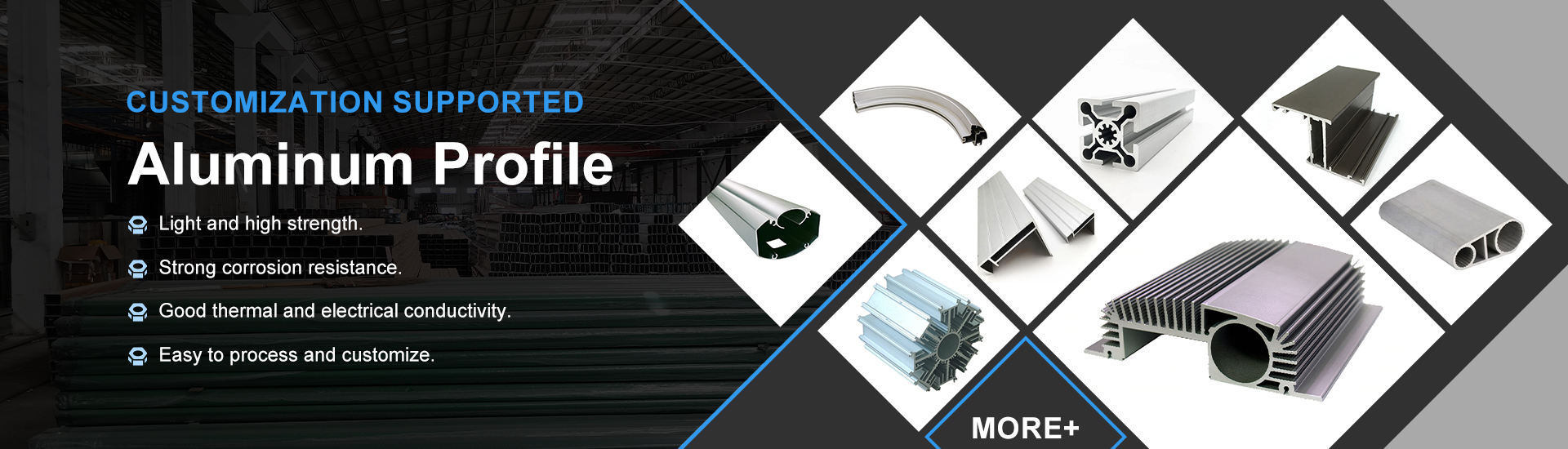

Aluminum C Profile is a type of extruded aluminum section shaped like the letter “C.” It is primarily produced from 6000 series alloys, such as 6063 or 6061, which provide a balance of strength, corrosion resistance, and lightweight performance. This profile is widely used in construction, framing, decoration, ventilation systems, and structural support. Typical wall thickness ranges from 1.0 mm to 3.0 mm, with dimensions customizable to project needs. It is available in various tempers, such as T5 and T6, offering good machinability and stable mechanical properties. Common surface treatments include anodizing, powder coating, polishing, brushing, and electrophoresis, which improve durability and enhance appearance. Aluminum C Profiles comply with standards like GB/T5237, ASTM B221, and EN specifications, ensuring consistent quality. With versatility in function and design, they are ideal for modern architectural and industrial applications.

Specifications of Aluminum C Profile

| Alloy |

6063, 6061, 6060 (6000 series) |

| Temper |

T3, T4, T5, T6 |

| Thickness (T) |

1.0 – 3.0 mm (customizable) |

| Width (W) |

Commonly 15–100 mm (custom sizes available) |

| Length (L) |

Standard 6 m; can be cut to size |

| Flange Size |

Adjustable according to design (e.g., 10–50 mm) |

| Surface Finishing |

Anodizing, Powder Coating, Electrophoresis, Polishing, Brushing, Wood Grain |

| Color Options |

Silver, Black, Bronze, Champagne, Gold, Customized RAL colors |

| Standards |

GB/T5237, ASTM B221, EN 755 |

| Customization |

Extrusion tooling, CNC machining, drilling, punching, cutting, assembly |

| Applications |

Building facades, doors & windows, curtain walls, frames, ventilation systems, industrial supports, decorative trims |

Stock list of Aluminum C Profile

| Size (Width × Flange) |

Thickness (T) |

Temper (State) |

Length (Standard Stock) |

| ½″ × ½″ (12.7 mm × 12.7 mm) |

1/16″ (≈ 1.6 mm) |

6063-T5 |

12 ft (≈ 3.66 m) |

| ½″ × ¾″ (12.7 mm × 19 mm) |

3/32″ (≈ 2.4 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| ½″ × ¾″ (12.7 mm × 19 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| ¾″ × ⅜″ (19 mm × 9.5 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| ¾″ × ¾″ (19 mm × 19 mm) |

1/16″ (≈ 1.6 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| ¾″ × ¾″ (19 mm × 19 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| ¾″ × 1 ½″ (19 mm × 38 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| 1″ × 1 ½″ (25 mm × 38 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

24 ft (≈ 7.3 m) |

| 1″ × 2″ (25 mm × 50 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| 1¼″ × ¾″ (32 mm × 19 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| 1¼″ × 1¼″ (32 mm × 32 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| 1½″ × ½″ (38 mm × 12.7 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| 1½″ × ¾″ (38 mm × 19 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| 1½″ × 1½″ (38 mm × 38 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

| 1¾″ × ¾″ (44 mm × 19 mm) |

1/8″ (≈ 3.2 mm) |

6063-T5 |

16 ft (≈ 4.9 m) |

If the standard specifications listed above do not meet your requirements, you can contact us directly to obtain customized product information.

Quick Quote.

Mechanical Properties of Aluminum C Profile

| Property |

6063-T5 |

6063-T6 |

Notes |

| Tensile Strength (Ultimate) |

≥ 145 MPa (21 ksi) |

≥ 230 MPa (33 ksi) |

Strength increases with artificial aging (T6 > T5) |

| Yield Strength (0.2% Offset) |

≥ 110 MPa (16 ksi) |

≥ 190 MPa (28 ksi) |

Higher in T6, suitable for structural load-bearing |

| Elongation at Break (%) |

≥ 8% |

≥ 8–10% |

Indicates ductility and formability |

| Hardness (Brinell HB) |

~ 60 HB |

~ 70 HB |

T6 temper is harder and more wear-resistant |

| Modulus of Elasticity (E) |

~ 69 GPa (10,000 ksi) |

~ 69 GPa (10,000 ksi) |

Independent of temper; standard for aluminum alloys |

| Shear Strength |

~ 95 MPa (14 ksi) |

~ 150 MPa (22 ksi) |

Important for joint and fastener design |

| Density |

2.70 g/cm³ |

2.70 g/cm³ |

Constant for aluminum alloys |

| Thermal Conductivity |

~ 201 W/m·K |

~ 201 W/m·K |

Good heat dissipation; useful in architectural and framing systems |

| Corrosion Resistance |

Excellent |

Excellent |

Well suited for anodizing and outdoor applications |

| Machinability |

Fair to Good |

Fair |

Easier in T5 due to lower hardness |

| Weldability |

Excellent |

Excellent |

Widely used in construction and fabrication |

What are Aluminum C Profile used for?

Aluminum C Profiles are widely used as structural and decorative components in both architectural and industrial fields. Their “C-shaped” cross-section provides strength, rigidity, and versatility, making them suitable for framing, edge protection, and support applications. In construction, they are commonly applied in doors, windows, curtain walls, partitions, ceilings, and façade systems, where they combine durability with an attractive appearance. They are also used in ventilation systems, cable management, and mounting frameworks due to their lightweight and corrosion-resistant properties. In industrial settings, Aluminum C Profiles serve as structural supports, machine frames, and protective trims. With a variety of surface finishes such as anodizing, powder coating, and brushing, they are suitable for both functional and decorative purposes, offering excellent adaptability in modern architectural design and engineering projects.

What are the characteristics of Aluminum C Profile?

What are the characteristics of Aluminum C Profile?

Aluminum C Profiles have several key characteristics that make them highly versatile in construction and industrial applications. They are lightweight yet strong, offering good load-bearing capacity while reducing overall structural weight. Made primarily from 6000 series alloys such as 6063 or 6061, they provide excellent corrosion resistance, making them suitable for indoor and outdoor use. Their mechanical properties vary with temper, with T5 and T6 offering good strength, dimensional stability, and machinability. Aluminum C Profiles also feature high formability and weldability, allowing easy fabrication, cutting, and assembly. Surface finishes such as anodizing, powder coating, brushing, and electrophoresis enhance both durability and appearance, with a wide range of color options available. They comply with international standards like ASTM B221, EN 755, and GB/T5237, ensuring consistent quality. Overall, Aluminum C Profiles combine strength, corrosion resistance, aesthetic flexibility, and ease of processing, making them ideal for modern architectural and industrial solutions.

Why Choose ZGGDMETAL as Your Aluminum C Profile supplier?

ZGGDMETAL stands out as a trusted manufacturer of aluminum profiles, offering a complete range of extrusion products tailored to architectural, industrial, and decorative applications. With advanced production lines and strict quality control, we ensure that every profile meets international standards such as GB/T5237, ASTM B221, and EN 755. Our factory specializes in 6000 series alloys like 6063 and 6061, available in tempers T3–T6, delivering the right balance of strength, formability, and corrosion resistance.

What are the characteristics of Aluminum C Profile?

What are the characteristics of Aluminum C Profile?