What Is Aluminum Foil Paper?

Aluminum foil paper is a composite material made by laminating thin aluminum foil onto a paper base through heat or adhesive bonding. It combines the flexibility and printability of paper with the excellent barrier and reflective properties of aluminum. The result is a lightweight yet durable packaging material that provides superior protection against light, moisture, air, and contaminants.

Typically, aluminum foil used in lamination ranges from 6 μm to 50 μm thick, while the total thickness of the composite sheet can vary from 0.05 mm to 2.0 mm, depending on the number of layers and application requirements. It can be supplied in rolls or sheets, with common widths up to 1500 mm, and is often available in embossed, coated, or printed surface finishes.

This material is widely used in food, pharmaceutical, and industrial packaging, such as cigarette liners, candy wrapping, airline meal trays, and insulation layers. Aluminum foil paper provides an excellent combination of barrier protection, decorative appeal, and processing flexibility, making it one of the most popular materials for moisture-proof and light-proof packaging.

In addition to standard foil-laminated paper, various surface treatments—such as coating, anodizing, printing, and embossing—can be applied to enhance sealing, corrosion resistance, and visual effects. Most aluminum foil paper products comply with ASTM, DIN, or GB standards for packaging materials and meet food-grade or pharmaceutical-grade safety requirements.

Specifications of Aluminum foil paper

| Alloy |

8011, 1235, 3003 |

| Temper |

O , H14, H18 |

| Thickness |

6 μm – 50 μm (0.006 mm – 0.05 mm) |

| Total Thickness |

0.05 mm – 2.0 mm |

| Width |

100 mm – 1500 mm (customizable up to 1600 mm) |

| Length / Roll Size |

As required by customer (commonly 50 m – 3000 m per roll) |

| Core Size |

76 mm (3 inch paper core or metal core optional) |

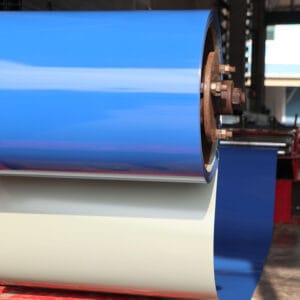

| Surface Treatment |

Plain, Printed, Embossed, Coated, Lacquered, Matt / Gloss finish |

| Lamination Type |

Aluminum + Paper / Aluminum + Paper + Plastic Film |

| Processing Methods |

Heat lamination, dry lamination, solvent-free lamination |

| Standards / Compliance |

ASTM B479, GB/T 3198, FDA Food Contact Safe, ISO 9001 |

| Color |

Silver (standard), Gold, custom printed colors available |

| Moisture Resistance |

Excellent – impermeable to water vapor and oxygen |

| Typical Applications |

Food packaging (chocolates, candies, meats, dairy), airline catering, cigarette wrapping, pharmaceutical packaging, insulation, decorative wrapping |

| Features |

Lightweight, high reflectivity, non-toxic, odor-free, printable, recyclable |

👉If you need customized product specifications, you can contact us directly.Quick Quote

Aluminum Foil Paper Size

| Aluminum Foil (Pure aluminum foil) |

6 μm – 50 μm (0.006 mm – 0.05 mm) |

| Foil + Paper / Film |

0.05 mm – 2.0 mm |

| Foil for Household |

Standard: 0.016 mm (16 μm) |

| Heavy duty foil paper |

0.024 mm (24 μm) |

| Common |

0.008 mm – 0.025 mm (8 μm – 25 μm) |

| Aluminum foil for pharmaceutical |

0.020 mm, 0.025 mm, 0.030 mm, 0.040 mm |

| Available Width |

100 mm – 1500 mm (customizable) |

| Length / Roll Size |

50 m – 3000 m per roll |

| Core Diameter |

76 mm (3-inch paper core) |

The inventory table is updated in real time, please get the latest inventory information.Quick Quote

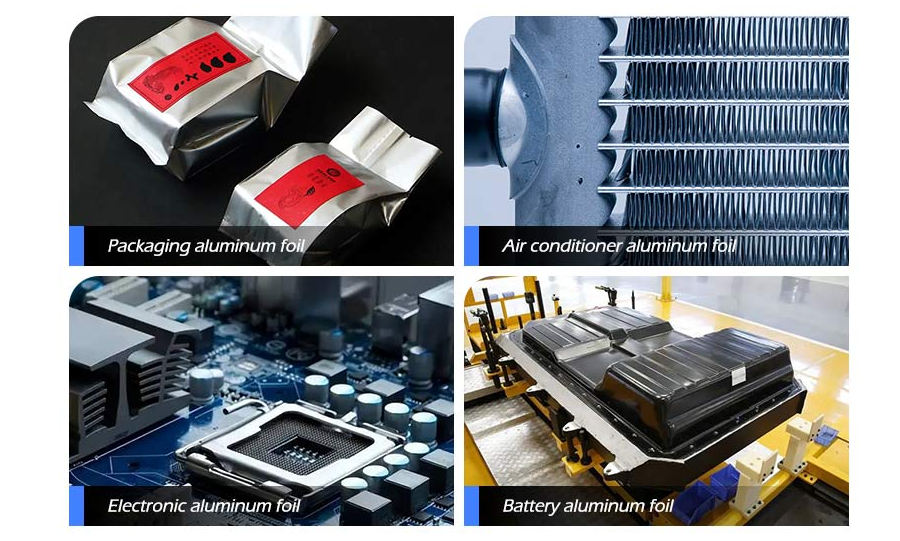

What are the applications of aluminum foil paper?

Aluminum foil paper is widely used across various industries due to its protective and decorative qualities.

-

Airline meal packaging

-

General meat and dairy packaging

-

Cigarette wrapping and inner liners

-

Chocolate and candy wrapping

-

Pharmaceutical and cosmetic packaging

What are the advantages of aluminum foil paper in food packaging

1. Premium Appearance:

The metallic luster provides strong light reflection and excellent printability, enhancing product presentation and brand appeal.

2. Excellent Barrier Performance:

Aluminum foil laminated paper blocks light, moisture, and air, preventing oxidation, bacterial growth, and flavor loss. It ensures that food retains freshness, aroma, and taste for a longer period.

3. High Protection:

It offers strong resistance to heat, water vapor, and gases. This makes it ideal for moisture-proof and hygienic packaging of foods such as fruits, snacks, and baked goods.

4. Eco-Friendly and Cost-Effective:

Aluminum foil paper is non-toxic, recyclable, and affordable compared to fully metallic packaging materials.

What Processing & Customization Services Can ZGGDMEAT Provide?

ZGGDMEAT offers a wide range of processing and customization services for aluminum foil paper to meet diverse packaging requirements. Our capabilities include:

-

Printing and Embossing:

High-quality logo and pattern printing, decorative embossing, and customized branding designs.

-

Surface Coating and Laminating:

Application of protective coatings, heat-seal layers, or barrier films to improve moisture resistance, sealing strength, and surface gloss.

-

Composite Lamination:

Multi-layer lamination with paper, plastic film (PE, PET, OPP), or other substrates to enhance durability and functionality.

-

Cutting and Slitting Services:

Precision cutting, slitting, and roll-to-sheet conversion to match specific product dimensions.

-

Custom Thickness and Width Options:

Available foil thicknesses from 6 μm to 50 μm and composite widths up to 1500 mm, tailored to customer needs.

-

Color and Finish Customization:

Options for silver, gold, matte, or glossy finishes, as well as custom-printed designs.

With flexible processing and strict quality control, ZGGDMEAT ensures every aluminum foil paper product meets international packaging standards and customer specifications.