Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

7020 aluminum tube is a high-strength Al-Zn-Mg alloy with excellent weldability and fatigue resistance. While slightly lower in strength than 7075 aluminum alloy, 7020 offers superior stress corrosion resistance, making it particularly well-suited for applications subject to dynamic loads. Common applications include railway components, motorcycle frames, scaffolding, and military structural components, all of which require exceptional safety and reliability.

👉 ZGGDMETAL offers a full range of 7020 aluminum tubes in stock and custom options. We have comprehensive mold resources, eliminating the need for additional mold costs and reducing procurement costs. Please review the detailed 7020 Aluminum Tube Specifications for more technical specifications and inventory information.

| Alloy | 7020 |

| Temper | T4, T5, T6, T651 |

| Equivalent Name | AA7020, ISO R209, EN AW-7020, AlZn4.5Mg1 |

| OD | 3 mm – 250 mm |

| WT | 0.5 mm – 50 mm |

| Length | 1000 mm – 6000 mm,Up to 12000 mm |

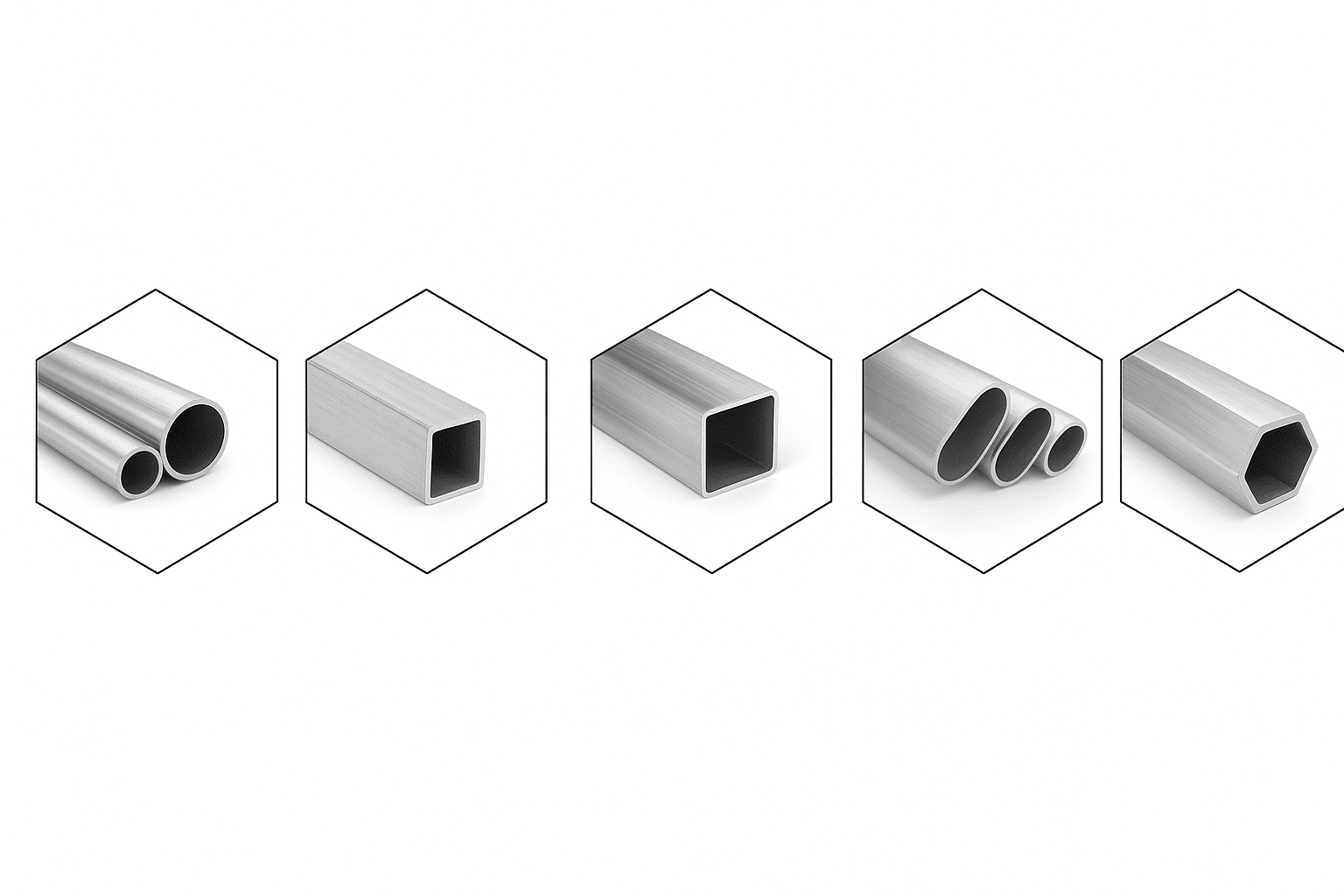

| Shape | Round Tube,Square Tube,Rectangular |

| Surface Finish | Mill Finish、Anodized、Powder Coated |

| Product Process | Extruded、Cold Drawn、Seamless |

| Standard | EN AW-7020, ASTM B210/B241, GB/T 3191, ISO R209(👉Click for details) |

| Payment & Trade Terms | FOB, CIF, EXW; support T/T, L/C |

| Packaging | Standard export packaging: plastic film + moisture-proof paper + wooden box or pallet, customized packaging is available |

| Applications | High-speed train bodies, motorcycle frames, aviation structural parts, welded frames, ground equipment, military vehicles, etc. |

| Outer Diameter (OD) | Wall Thickness (WT) | Metric (OD × WT) | Imperial (OD × WT) | Length |

|---|---|---|---|---|

| 3 mm | 0.8 mm | 3 mm × 0.8 mm | 0.118″ × 0.032″ | ≤ 12 m (custom) |

| 20 mm | 2 mm | 20 mm × 2 mm | 0.787″ × 0.079″ | ≤ 12 m |

| 50 mm | 3 mm | 50 mm × 3 mm | 1.97″ × 0.118″ | ≤ 12 m |

| 100 mm | 5 mm | 100 mm × 5 mm | 3.94″ × 0.197″ | ≤ 12 m |

| 300 mm | 12.7 mm | 300 mm × 12.7 mm | 11.81″ × 0.5″ | ≤ 12 m |

| Outer Diameter (OD) | Wall Thickness (WT) | Metric (OD × WT) | Imperial (OD × WT) | Length |

|---|---|---|---|---|

| 5 mm | 0.5 mm | 5 mm × 0.5 mm | 0.197″ × 0.020″ | ≤ 12 m |

| 25 mm | 1 mm | 25 mm × 1 mm | 0.984″ × 0.039″ | ≤ 12 m |

| 80 mm | 2 mm | 80 mm × 2 mm | 3.15″ × 0.079″ | ≤ 12 m |

| 150 mm | 6 mm | 150 mm × 6 mm | 5.91″ × 0.236″ | ≤ 12 m |

| 220 mm | 10 mm | 220 mm × 10 mm | 8.66″ × 0.394″ | ≤ 12 m |

| Tensile Strength | ≥ 350 MPa |

| Yield Strength | ≥ 280–290 MPa |

| Elongation | ≥ 10% |

| Brinell Hardness (HBW) | ≈ 110 |

| Fe | ≤ 0.4% |

| Si | ≤ 0.35% |

| Mn | 0.05~0.5% |

| Cr | 0.1~0.35% |

| Cu | ≤0.2% |

| Zr | 0.08%~0.2% |

| Zn | 4~5% |

| other | Others 0.5% / Others total 0.15% |

| AL | Balance |

| AA (USA) | AA7020 |

| EN (Europe) | EN AW-7020 |

| ISO | ISO R209 / AlZn4.5Mg1 |

| DIN (Germany) | DIN 3.4335 |

| ASTM (USA) | ASTM B210 / B221 / B241 |

| GB (China) | GB/T 3191 |

| BS (UK) | BS H17 |