Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

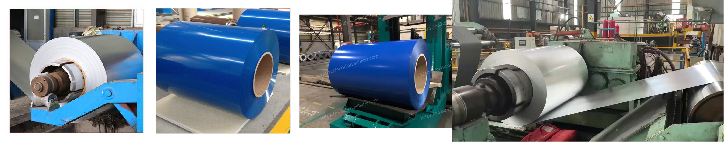

3003 color coated aluminum coil and sheet is made from a rust-resistant aluminum-manganese alloy base (3003) with a PE or PVDF coating. It offers excellent corrosion resistance, vibrant color adhesion, and good formability. Ideal for roofing, wall cladding, ceilings, signage, and composite panels.

3003 color coated aluminum is a widely used aluminum-manganese alloy with excellent anti-corrosion properties, especially ideal for environments exposed to moisture or chemicals. After applying PE or PVDF coating, it offers enhanced durability, UV protection, and decorative aesthetics.

The material is light, formable, and highly resistant to oxidation, making it the perfect choice for both architectural cladding and indoor applications.

| Alloy | 3003 |

| Temper | O, H12, H14, H16, H18, H22, H24, H26, H28, H112 |

| Thickness | 0.2 mm – 6.0 mm (customizable) |

| Width | 900 mm – 2650 mm (coil up to 2200 mm) |

| Length | Standard 6000 mm (sheet), coil length as required |

| Coating Thickness | PE: 18–25 μm, PVDF: 25–30 μm (one side); 5–10 μm (back side) |

| Coating Hardness | Pencil hardness ≥ 2H |

| Weather Resistance | PE coating: 7–10 years; PVDF coating: 20–25 years (outdoor durability) |

| Surface Treatment | Brushed, Mirror, Embossed, Stucco, Sand-blasted, Wood/Marble Grain |

| Color | RAL color system, customized solid colors, metallic, wood & marble patterns |

| Standards | ASTM B209, EN 485, EN 573, GB/T 3880, AMS 4006/4008, QQ-A-250/2 |

| Applications | Building facades, roofing, ceilings, curtain walls, decorative panels, signage, refrigeration equipment, interior & exterior decoration |

| Alloy | Temper | Thickness | Width | Coating Type |

|---|---|---|---|---|

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| 3003 | O | 0.10 mm | 1000 mm | PE |

| Property | Typical Value (O Temper) | Typical Value (H14 Temper) | Standard Reference |

|---|---|---|---|

| Tensile Strength (MPa) | 95 – 130 | 130 – 180 | ASTM B209 / EN 485-2 |

| Yield Strength (MPa) | ≥ 35 | ≥ 115 | ASTM B209 / EN 485-2 |

| Elongation (%) | ≥ 20 | ≥ 5 | ASTM B209 / EN 485-2 |

| Hardness (HB) | 28 – 35 | 40 – 65 | Brinell Hardness |

| Elastic Modulus (GPa) | ~69 | ~69 | Typical Aluminum Alloy Value |

| Density (g/cm³) | 2.73 | 2.73 | Standard for Al-Mn Alloy |

3003 Colour Coated Aluminum Sheet is widely used in both architectural and industrial applications due to its lightweight, corrosion resistance, and excellent decorative finish. Its polyester (PE) or PVDF coating provides weather durability and long-lasting color performance, making it suitable for outdoor and indoor projects.

Typical uses include:

Building facades and curtain walls – offering strong durability, UV resistance, and aesthetic appeal.

Roofing and ceiling panels – lightweight and corrosion-resistant for long service life.

Decorative wall cladding and interior panels – available in multiple surface finishes such as wood grain, marble, brushed, or embossed patterns.

Signage and advertising boards – providing smooth surfaces with bright, lasting colors.

Refrigeration and HVAC equipment – excellent thermal conductivity and corrosion resistance.

Furniture and household appliances – combining formability with stylish surface designs.

With its combination of strength, versatility, and decorative options, 3003 colour coated aluminum sheet is a preferred material in modern construction, decoration, and industrial manufacturing.

3003 Colour Coated Aluminum Sheet combines the advantages of the 3003 aluminum alloy with protective and decorative surface coatings. Its main characteristics include:

Excellent Corrosion Resistance – The manganese in 3003 alloy provides strong resistance to atmospheric and chemical corrosion, making it suitable for outdoor applications.

Lightweight with Good Strength – Lower density than steel while maintaining reliable strength; tensile strength ranges from 95–180 MPa depending on temper.

Superior Workability – Easy to bend, cut, weld, and form, making it adaptable for complex architectural and industrial designs.

High Surface Durability – Coatings such as PE or PVDF offer long-lasting color stability, UV resistance, and weather durability (up to 25 years for PVDF).

Versatile Surface Options – Available in brushed, embossed, mirror, stucco, wood grain, and marble finishes for both decorative and functional purposes.

Wide Range of Tempers and Sizes – Supplied in O, H14, H16, H18, H22, H24, and other tempers, with thicknesses from 0.2 mm to 6 mm and widths up to 2650 mm.

International Standards Compliance – Meets ASTM B209, EN 485, GB/T 3880, and other industry standards.

Overall, 3003 colour coated aluminum sheet offers an ideal balance of durability, formability, and aesthetic appeal, making it a preferred material for building facades, roofing, ceilings, decorative panels, and refrigeration equipment.

ZGGDMetal can provide a wide range of surface treatments for 3003 Colour Coated Aluminum Sheet to meet both decorative and functional needs. The available options include:

Brushed finish – delivering a modern metallic texture with linear patterns.

Mirror finish – highly reflective surface for decorative and high-end applications.

Embossed / Stucco finish – enhancing strength and appearance with textured patterns.

Sand-blasted finish – matte effect with uniform roughness.

Wood grain and marble patterns – realistic decorative coatings for architectural use.

Color-coated finishes (PE, PVDF, etc.) – providing smooth, durable surfaces with excellent weather resistance and long-lasting colors.

With these treatments, ZGGDMetal can offer products that combine corrosion resistance, durability, and aesthetic versatility, suitable for construction, decoration, and industrial applications.