Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

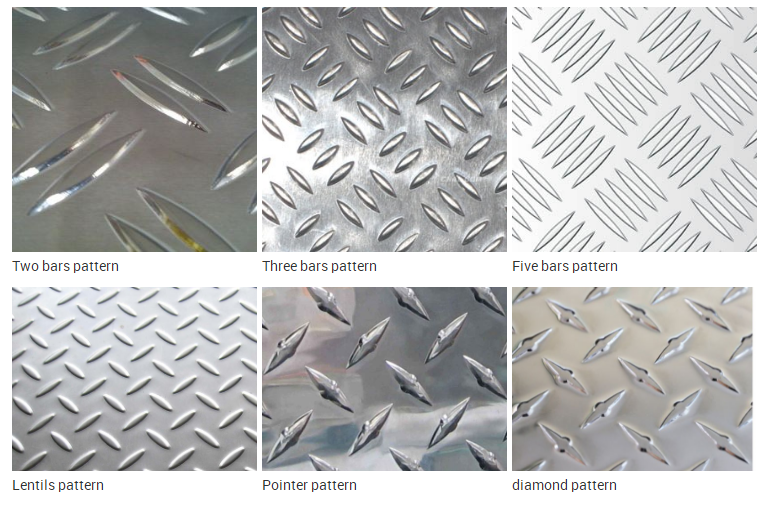

3003 Aluminum Checkered Plate is a medium-strength, manganese-alloyed aluminum sheet widely used for both functional and decorative purposes. With an aluminum content of about 96.8% and 1.0–1.5% manganese, it provides excellent corrosion resistance, good weldability, and reliable forming properties. The surface features raised patterns such as diamond, 5-bar, or 3-bar designs, which enhance slip resistance while also delivering an attractive appearance.

3003 Aluminum checkered plate is a type of aluminum sheet made from the 3003 alloy, which contains about 96.8% aluminum with 1.0–1.5% manganese for added strength and corrosion resistance. Unlike flat sheets, its surface is embossed with raised patterns such as diamond, 5-bar, or 3-bar designs. These patterns not only improve slip resistance but also provide decorative appeal.It is available in various thicknesses, typically from 1.0 mm to 8.0 mm, with standard tempers like O, H14, H22, and H24. The plate can be supplied in mill finish, polished, anodized, or color-coated surfaces, and it meets international standards such as ASTM B209 and GB/T 3880.

Due to its lightweight, durability, and excellent corrosion resistance, 3003 aluminum checkered plate is widely used for flooring, stair treads, vehicle decks, building facades, and industrial platforms. It is especially popular in transportation, construction, and decorative applications where both strength and appearance are important.

| Alloy | 3003 (Al-Mn alloy) |

| Temper | O, H12, H14, H16, H18, H22, H24, H26, H114, H194, H234 |

| Thickness | 1.0 mm – 8.0 mm (sheet 0.2–6 mm; plate up to 250 mm, customizable) |

| Width | 900 mm – 2650 mm (common: 1000 / 1250 / 1500 / 1600 mm) |

| Length | 2000 mm – 6000 mm (custom cut; common sizes: 48×96″, 48×120″, 60×144″) |

| Surface Finish | Mill finish, Polished, Bright, Anodized, Color Coated, Brushed, Sand Blasted |

| Pattern (Embossing) | Diamond, 5-bar, 3-bar, 2-bar, Single-rib |

| Standards | ASTM B209 / B632, AMS 4006 / 4008, GB/T 3880, ISO 6361 |

| Applications | Flooring, Stair treads, Vehicle decks, Building facades, Oil tanker platforms, Industrial platforms, Decorative walls |

| Alloy | Temper | Thickness | Width |

|---|---|---|---|

| 3003 | H22 | 0.063″ | 48″, 96″, 120″ |

| 3003 | H22 | 0.125″ | 48″ |

| 3003 | H22 | 0.10″ | 60″ |

| 3003 | H22 | 0.188″ | 48″ or 60″ |

| 3003 | H22 | 0.25″ | 48″ |

| 3003 | H22 | 0.25″ | 12″ |

| 3003 | H14 / H22 | 0.045″ – 0.500″ | unspecified |

| 3003 | – | 0.125″ (1/8″) | 48″ or 96″ |

| 3003 | – | 0.190″ (3/16″) | multiple |

3003 Aluminum Checkered Plate is widely used in applications that require both durability and slip resistance. With its raised patterns such as diamond, 5-bar, or 3-bar, it provides excellent anti-slip performance, making it suitable for flooring, stair treads, vehicle decks, and industrial walkways. Its corrosion resistance and lightweight properties also make it ideal for marine platforms, oil tanker steps, and construction scaffolding.

In addition, 3003 tread plate is often used for decorative and protective purposes in building facades, interior wall panels, ceilings, and architectural trims. It is also popular in the transportation industry, including truck beds, trailer ramps, and bus flooring. The combination of strength, formability, and aesthetic appeal allows it to serve both functional and decorative roles across construction, transportation, and industrial projects.

3003 Aluminum Checkered Plate is characterized by its excellent corrosion resistance, moderate strength, and good workability. As an aluminum-manganese alloy, it offers better mechanical strength than pure aluminum while maintaining lightweight properties. The surface is embossed with raised patterns such as diamond, 5-bar, or 3-bar, which provide strong slip resistance and a decorative appearance.

It is easy to weld, bend, and form, making it suitable for a wide range of applications in construction, transportation, and industrial platforms. Available in tempers like O, H14, and H22, and thicknesses from 1 mm to 8 mm, it can be supplied in various finishes including mill finish, polished, anodized, or color coated. Conforming to standards such as ASTM B209 and GB/T 3880, it combines durability, aesthetics, and versatility, making it one of the most practical choices for anti-slip and decorative surfaces.

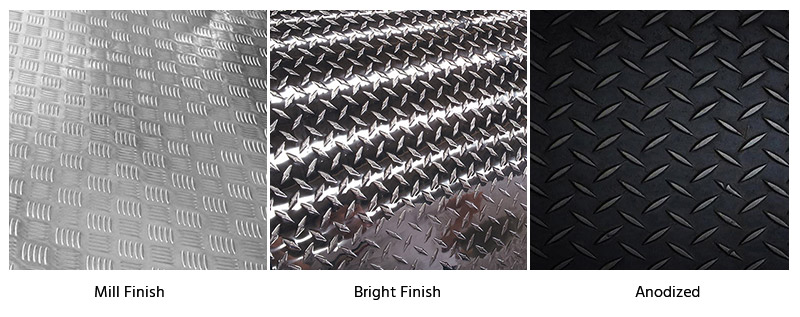

ZGGDMetal can provide a wide range of surface treatments for 3003 Aluminum Checkered Plate, including:

Mill finish – standard smooth finish straight from rolling

Polished / Bright finish – enhanced reflectivity and decorative appeal

Brushed / Hairline finish – uniform linear texture for architectural use

Sand blasted – matte and anti-glare surface

Embossed / Checkered – raised patterns such as diamond or 5-bar for anti-slip

Anodized – improved corrosion resistance and surface hardness

Color coated / Painted – protective and decorative coating in different colors

Film laminated (PVC / Blue film) – protective surface layer during handling and installation

These options ensure that ZGGDMetal can meet diverse requirements in construction, transportation, and decorative applications.