What is 2124 Aluminum ?

2124 aluminum is well known for its exceptional strength-to-weight ratio and reliable structural stability. When heat-treated, it delivers outstanding tensile strength, excellent fatigue resistance, and strong fracture toughness—especially in medium and heavy gauge sections.

The 2124 T851 aluminum plate offers even higher strength than many common aluminum alloys and is considered a true aerospace-grade material. It is widely used in aircraft structures and other high-load components that require superior mechanical performance.

Compared with the 2024 alloy, 2124 aluminum provides better strength retention and improved creep resistance at elevated temperatures, making it a preferred choice for critical aerospace and high-performance engineering applications.

Advantages of 2124 t851 Aluminum Plate

- High Strength

In the T851 temper, 2124 aluminum delivers notably higher tensile and yield strength, making it ideal for components exposed to heavy loads and demanding service conditions.

- Excellent Fatigue Resistance

This alloy maintains strong fracture toughness and impressive fatigue performance, even in thicker gauges, which is critical for aerospace and high-stress structural applications.

- Good Machinability

Both T351 and T851 tempers offer reliable machinability and favorable forming characteristics, allowing precise shaping and efficient production.

- Corrosion Protection

While the alloy itself offers moderate corrosion resistance, surface treatments such as anodizing or protective coatings are recommended to enhance durability based on specific application needs.

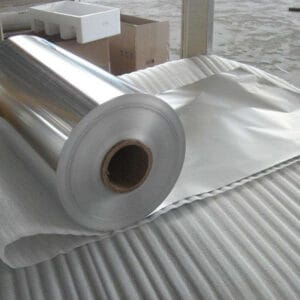

Specification of 2124 t851 Aluminum Plate

| Product Name |

2124 T851 Aluminum Sheet |

| Thickness |

38 mm – 152 mm |

| Width |

800 mm – 2,000 mm |

| Length |

2,000 mm – 6,000 mm; cut-to-size service available |

| Standards |

AMS 4101, ASTM B209, EN standards; MTC EN 10204-3.1 / 3.2 |

| MOQ |

2 ton |

| Services |

Thin/medium thickness plates can be custom-produced according to requirements. |

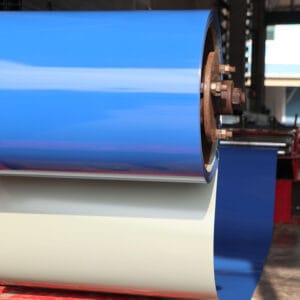

| Surface Finish |

anodizing&Aclad |

We also offer 2124 aluminum plates in other tempers, such as T351, O, and other custom sizes. We will provide you with the latest aluminum plate specifications.

2124 Aluminum composition

| Cu |

4.0 – 4.9 |

| Mg |

1.2 – 1.8 |

| Mn |

0.3 – 0.6 |

| Fe |

≤ 0.50 |

| Si |

≤ 0.50 |

| Zn |

≤ 0.30 |

| Ti |

≤ 0.15 |

| Others |

Trace amounts |

| Al |

Balance |

2124 T851 Aluminum Plate Properties

| Ultimate Tensile Strength (UTS) |

480–490 MPa |

| Yield Strength (0.2% Rp0.2) |

430–445 MPa |

| Elongation at Break |

5–8% |

| Elastic Modulus (E) |

71–73 GPa |

| Fatigue Strength |

120–130 MPa |

| Hardness (Brinell HB) |

~120–140 HB |

| Density |

2.78 g/cm³ |

Application of 2124 t851 Aluminum

2124 T851 aluminum plates are heat-treated to achieve higher strength while maintaining controlled stress levels and excellent fatigue resistance. This combination of properties makes the alloy especially suitable for critical load-bearing structures.

1.Aerospace Structural Components:

Widely used in wing panels, fuselage skins, interior cabin panels, and other high-strength aircraft parts where durability and performance are essential.

2.Spacecraft and Rocket Structures:

Commonly applied in rocket body skins, outer shells of energy modules, fuel tank wall panels, and load-bearing wing or fin assemblies. Its stability and strength retention at elevated temperatures make it well suited for advanced aerospace systems.