ZGGDMETAL Aluminum Tube Procurement Guide

- All listed specifications are in stock and can be customized and ordered in bulk. Standard delivery time for export (including customs clearance and transportation) is about 7 working days after order confirmation.

- As an aluminum tube manufacturer with large-scale extrusion and finishing capabilities, ZGGDMETAL offers factory direct prices, which can reduce your procurement costs by up to 10% without compromising quality.

- Each aluminum tube undergoes strict quality inspection to ensure product quality that meets international standards such as AMS, ASTM and EN.

👉 If you need to purchase in bulk or customize, ZGGDMETAL’s standard sizes are equipped with molds, without additional mold costs. For specific details, please refer to the 2024 t3 aluminum alloy tube

Zggdmetal 2024 t3 aluminum tube specifications

| 2024 Aluminum Tube |

| Tempers |

O, T3, T3511, T4 |

| Equivalent Designations |

2024, EN AW-2024, AW-AlCu4Mg1, AU4G1, 3.1355, A92024, AlCu4Mg1, AlCuMg2 |

| Product Types & Dimensions |

Seamless,Extruded |

| 2024 Extruded Round Tube |

OD: 0.314″–16.54″ (8–420mm)Wall Thickness: 0.197″–1.97″ (5–50mm) |

| 2024 Cold Drawn Round Tube |

OD: 0.2″–8.66″ (5–220mm)Wall Thickness: 0.02″–0.39″ (0.5–10mm) |

| A92024 Seamless Round Tube |

OD: 3.54″–11.81″ (90–300mm)Wall Thickness: 0.2″–0.79″ (5–20mm) |

| 2024 Forged Round Tube |

OD: 7.87″–39.37″ (200–1000mm)Wall Thickness: 0.79″–3.94″ (20–100mm) |

| 2024 Thin Wall Round Tube |

OD: 3.54″–11.81″ (90–300mm)Wall Thickness: 0.01″–2″ (0.25–50mm) |

| Length |

Max. 30 metersFixed Length / Cut-to-Length / Custom |

| Color Options |

Silver, Gold, Natural, Bronze, Champagne, Red, Grey, Black, Customized |

| Surface Treatments |

Anodizing, Powder Coating, Plating, etc. [👉Click to view surface treatment details] |

| Secondary Processing |

CNC Cutting, Drilling, Etching, Bending, Welding, etc. [👉Click to view processing services] |

| Production Processes |

Extrusion, Cold Drawing, Forging |

| Packaging |

Standard Export Packaging or Customized per Customer Requirements |

| Applicable Standards |

AMS WW-T-700/3, AMS 4086, AMS 4087, AMS 4088, ASTM B210, ASTM B221, ASTM B241, AMS QQ-A-200/3, AMS 4152, AMS 4165, ASME SB241 |

👉 If the standard sizes listed above do not meet your requirements, you can contact us directly for custom product specifications. Quick quote

ZGGDMETAL 2024 Aluminum tube -Physical Properties by Temper

|

2024-O |

2024-T3 |

2024-T4 |

2024-T351 |

| Tensile Strength |

100–200 MPa |

320–480 MPa |

310–480 MPa |

330–460 MPa |

| Shear Strength |

130 MPa |

290 MPa |

290 MPa |

290 MPa |

| Fatigue Strength |

90 MPa |

140 MPa |

140 MPa |

140 MPa |

| Elastic Modulus |

71 GPa |

71 GPa |

71 GPa |

71 GPa |

| Brinell Hardness |

49 |

120 |

120 |

120 |

| Elongation at Break |

15% |

15% |

16% |

13% |

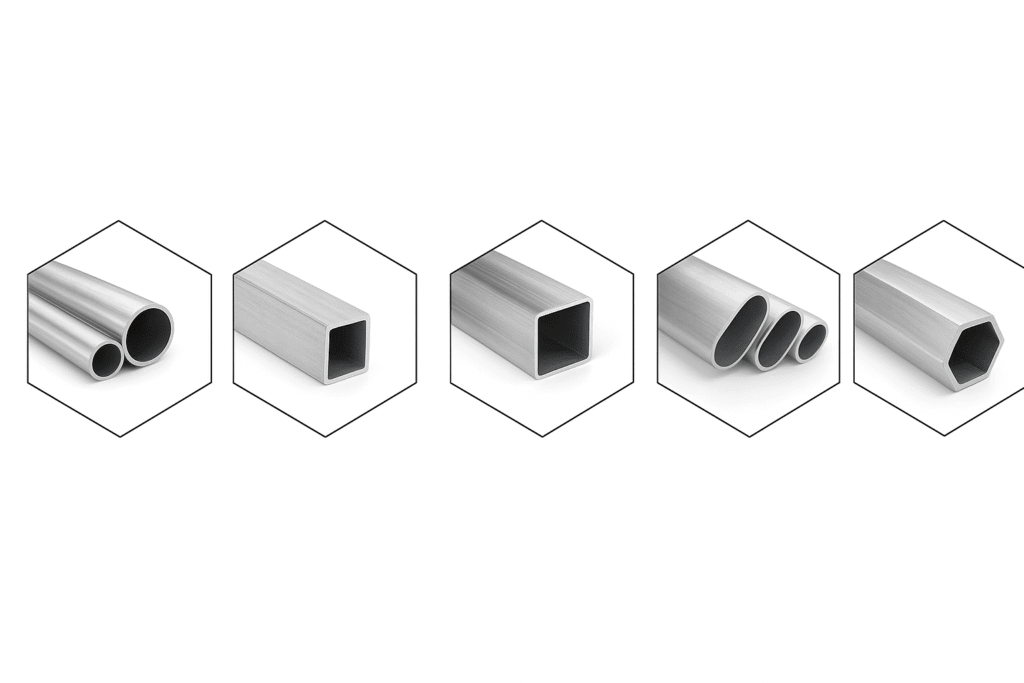

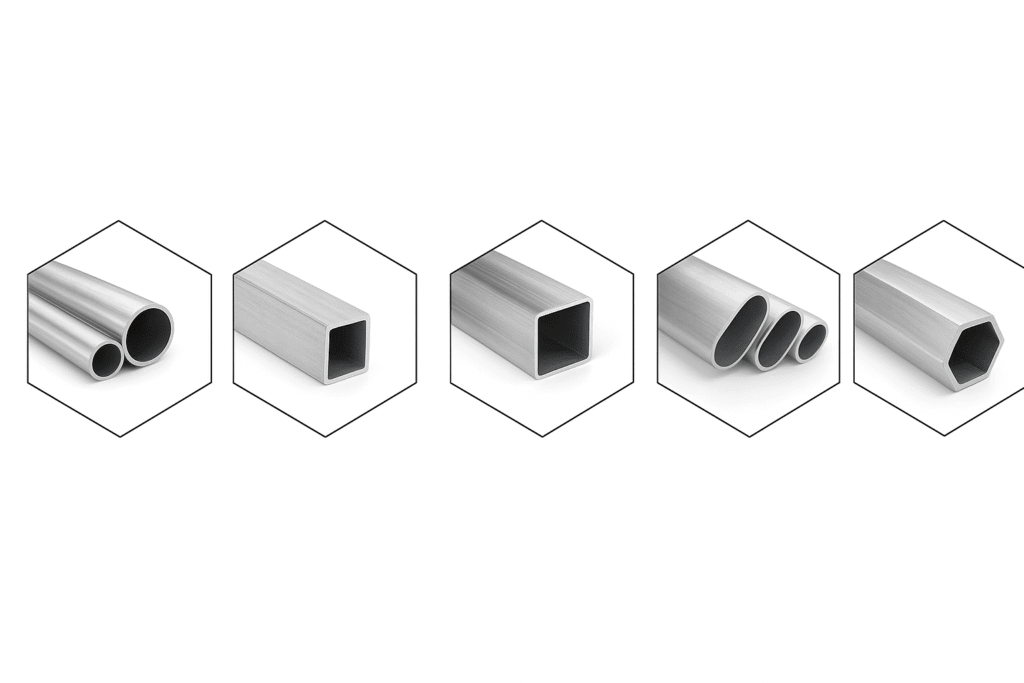

What shapes of 2024 aluminum tubes can ZGGDMETAL produce?

ZGGDMETAL can produce various shapes of 2024 aluminum tubes, including 2024 aluminum round tubes, 2024 aluminum square tubes, 2024 aluminum rectangular tubes, 2024 aluminum oval tubes, 2024 aluminum hexagonal tubes, 2024 aluminum special-shaped tubes and 2024 aluminum semi-circular tubes.

What surface treatments can ZGGDMETAL provide for 2024 aluminum tubes?

ZGGDMETAL offers a wide range of surface treatment options for 2024 aluminum tubes to meet diverse application needs. Available finishes include anodizing, powder coating, electroplating, mechanical polishing, ceramic coatings, and chemical treatments, among others. Each process is tailored to enhance corrosion resistance, surface hardness, or aesthetic appearance according to customer specifications.

What CNC machining services does ZGGDMETAL provide for 2024 aluminum tubes?

ZGGDMETAL provides comprehensive CNC and secondary processing services to support custom manufacturing needs. These services include:

- Precision cutting & drilling

- CNC milling & turning

- Gradual wall thinning

- Laser cutting & etching

- Welding & heat treatment

- Mechanical processing & forming

- Tube bending, shaping, and slotting

With advanced equipment and experienced technicians, we ensure high precision, high quality and fast delivery time.

What production equipment does ZGGDMETAL use as a 2024 aluminum pipe supplier?

As a professional manufacturer of 2024 aluminum pipes, ZGGDMETAL is equipped with advanced double-action reverse extrusion lines, featuring:

- Gas-injection rapid heating furnaces

- Thermal stripping units

- Infrared continuous temperature monitoring systems

- Water vapor quenching systems for precise extrusion control

- Horizontal 14-roller straightening machines

- Precision cutting and bounce inspection systems

With advanced production lines and processes, strict pressure pipeline component quality control system ensures the quality and performance of each pipe, providing higher safety and reliability for your application projects.Quick quote

What are the advantages of 2024 aluminum tubes?

- Aviation grade aluminum alloy, high strength, light weight

- Excellent fatigue strength and creep resistance, suitable for load-bearing structures

- Precise size control to meet the needs of high-precision machinery

- Strict factory quality inspection, with material report and mechanical properties test

- Support international export, rich experience, free samples

What are the Appliacation of 2024 aluminum tubes?

- Aviation structural parts: wing frames, skin brackets, landing gear parts

- Precision machinery and molds: sports robot arms, engineering machinery frames

- Military/defense products: structural supports, sheath components

- Racing/karting: lightweight, high-strength chassis brackets

- High-voltage equipment structural parts: support pipes, load-bearing frame systems

What are the advantages of ZGGDMETAL?

ZGGDMETAL, as one of China’s leading aluminum manufacturers, offers an extensive range of extrusion molds to support the full series production of 2024 aluminum tubes in various sizes and shapes. With highly competitive pricing and a streamlined one-stop supply chain, we help simplify your sourcing process and reduce procurement costs.

All products are manufactured under strict quality management systems, including ISO 9001, GJB 9001, AS9100, and IATF 16949, and are supported by Nadcap certifications for non-destructive testing, heat treatment, and materials testing.

Customized production is available to meet Japanese, European, American, and other international standards, as well as specific customer requirements upon request.Quick quote