Aluminum strips and foil tapes are indispensable materials used across various industries, from HVAC systems and electronics to automotive manufacturing and construction. Their unique blend of lightweight durability, conductivity, and resistance to environmental stress makes them ideal for both industrial and residential applications.

In this guide, we’ll take a deep dive into the most common uses of aluminum strips and foil tapes, explain what makes these materials so versatile, and offer insights into their real-world applications—especially in climates like Las Vegas, where heat resistance and durability are vital.

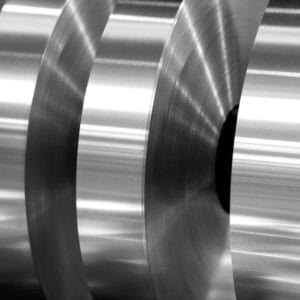

What Exactly Is an Aluminum Strip?

An aluminum strip refers to a long, narrow piece of aluminum that’s produced by slicing larger coils or sheets into slimmer formats. These strips can range widely in both width and thickness, making them suitable for custom applications in different industries. Depending on the alloy used—such as 1050, 3003, or 5052—they may emphasize conductivity, corrosion resistance, or mechanical strength.

How Are Aluminum Strips Commonly Used?

1. Electrical & Electronic Components

Due to their excellent electrical conductivity and affordability, aluminum strips are widely used in:

- Transformer windings and motor components

- EMI shielding for electronic cables

- Printed circuit boards and capacitors

These applications benefit from the strip’s ability to manage current while offering cost-efficiency over copper.

2. HVAC and Energy-Efficient Building Systems

Aluminum strips are integral to HVAC systems:

- Used to seal air ducts and join insulating panels

- Provide radiant heat reflection in insulation layers

- Help minimize energy loss by creating tight seals in ventilation networks

In dry, hot climates like Nevada, foil-coated aluminum strips are often applied to reduce heat penetration and save energy costs.

3. Automotive and Aerospace Engineering

Lightweight and resistant to corrosion, aluminum strips are essential in:

- Radiator fins and thermal management systems

- Decorative trims and bodywork in cars

- Temporary aircraft repairs using “speed tape,” which is pressure-sensitive aluminum tape used to patch non-critical surfaces

The aerospace industry values aluminum for its high performance under extreme temperature and wind conditions.

4. Consumer Appliances and LED Technology

In home appliances and electronics:

- Aluminum strips are used for decorative accents and housing frames

- Act as heat spreaders in LED lighting systems

- Offer a sleek, modern look while aiding in thermal control

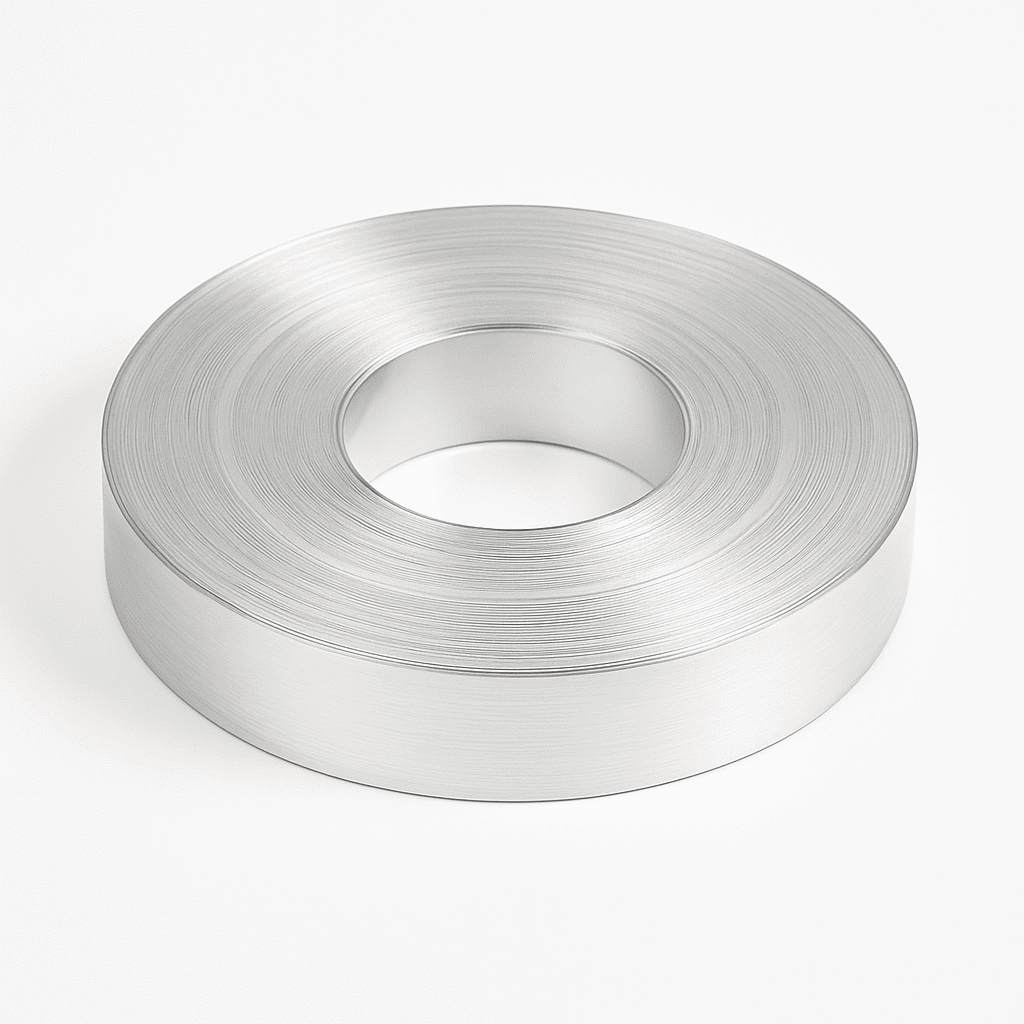

5. Packaging and Protective Sealing

When rolled into thin foil and combined with adhesives, aluminum strips become vital in:

- Food and beverage packaging

- Blister packs in the pharmaceutical industry

- Tamper-proof seals for containers and bottles

These uses depend on aluminum’s barrier properties against moisture, light, and oxygen.

What Is Aluminum Foil Tape Used For?

Aluminum foil tape is made by bonding aluminum with a high-strength adhesive backing, enabling it to stick securely to surfaces for sealing, shielding, and insulating.

Most Common Use Cases:

- Duct sealing in HVAC systems: Prevents leaks and improves airflow efficiency

- Insulation joints and seams: Reflects heat and provides moisture protection

- Cold chain logistics: Used in refrigerators and cold storage for secure seals

- Aircraft body repairs: Temporary high-speed fixes with pressure-sensitive foil tape

- Electronic shielding: Prevents electromagnetic interference in sensitive components

- DIY and home improvement: Ideal for patching gaps, reinforcing insulation, or securing ventilation hoses

Because of its resistance to UV rays, heat, and moisture, foil tape is particularly useful in long-term outdoor or industrial setups.

Local Use Tips: Aluminum Tape in Las Vegas

In places like Las Vegas, where extreme summer temperatures challenge the integrity of HVAC systems and outdoor construction materials, aluminum tape offers a reliable solution:

- Seals ventilation leaks to reduce energy loss

- Provides heat reflection to lower indoor temperatures

- Resists UV degradation, ensuring long-lasting performance on rooftops and exteriors

Local suppliers such as Home Depot (Henderson), Lowe’s, and specialty outlets like AlcoA Supply typically stock various aluminum tape grades for both residential and commercial applications.

Why Choose Aluminum Strips or Tape?

- Lightweight but durable: Perfect for transportation and aerospace

- Highly conductive: Efficient in electrical systems

- Corrosion-resistant: Holds up well in humid or outdoor conditions

- Thermally stable: Excellent in both hot and cold environments

- Recyclable: Environmentally friendly with reduced material waste

- Versatile: Customizable to fit everything from fine electronics to large-scale building projects

These benefits make aluminum one of the most adaptable metals across both heavy industry and household use.

Conclusion

Aluminum strips and foil tape serve as fundamental materials in modern manufacturing, energy efficiency, and household maintenance. Their combination of performance, affordability, and adaptability ensures they will remain indispensable in the years to come.

Whether you’re an engineer designing a transformer, a contractor sealing HVAC ducts, or a homeowner insulating your attic—aluminum tape and strip products are reliable tools that deliver results.