When it comes to lightweight and corrosion-resistant tubing solutions, 3003 aluminum pipe stands out as one of the most reliable and versatile options. Whether you’re working on an HVAC system, a marine project, or general fabrication, 3003 aluminum tube offers the performance and flexibility that many industries need.

In this guide, we’ll cover everything you need to know about 3003 aluminum pipe — from its basic properties and manufacturing standards to its typical applications and available sizes.

What is 3003 Aluminum Pipe?

3003 aluminum pipe is made from an aluminum-manganese alloy that contains about 1.2% manganese. This composition gives the pipe excellent corrosion resistance, good workability, and moderate strength. Compared to pure aluminum, 3003 alloy has improved mechanical properties, making it suitable for both indoor and outdoor use.

This material is not heat-treatable but can be strengthened by cold working. It is often supplied in various tempers such as H14 (strain-hardened) or O (annealed), depending on the desired balance of strength and formability.

Key Features of 3003 Aluminum Tube

Here are some important features that make 3003 aluminum tube a preferred choice in many industries:

- Excellent corrosion resistance: Ideal for use in environments exposed to moisture, chemicals, and outdoor conditions.

- Good formability: Easily bent, shaped, or deep drawn without cracking.

- Lightweight: Offers weight savings without sacrificing performance.

- Weldable: Suitable for common welding methods such as TIG and MIG welding.

- Non-heat treatable: Strength can be improved through cold working instead.

Applications of 3003 Aluminum Pipe

Thanks to its balanced properties, 3003 aluminum pipe is widely used in a variety of fields:

- HVAC systems: Ideal for air ducts, condensers, and evaporator coils due to its thermal conductivity and corrosion resistance.

- Automotive: Used in fuel lines and radiators where lightweight and durability are important.

- Marine industry: Resists corrosion in wet and salty environments, making it suitable for boat fittings and railings.

- Architecture and decoration: Applied in curtain walls, trims, handrails, and decorative tubes.

- Food and chemical equipment: Safe and stable for contact with various substances, often used in brewing and kitchen facilities.

Available Specifications and Standards

At ZGGDMETAL, we supply 3003 aluminum tubes that meet various industry standards to ensure quality and performance:

- Standards: ASTM B210, EN 573, EN 755

- Tempers: O, H12, H14, H18, H22

- Outer Diameter (OD): 6 mm – 150 mm

- Wall Thickness: 0.5 mm – 10 mm

- Length: Standard lengths of 1 m to 6 m, with custom lengths available

- Tolerances: Produced according to international dimensional standards or custom specs

We also offer cutting, deburring, and surface treatment services to meet your exact requirements.

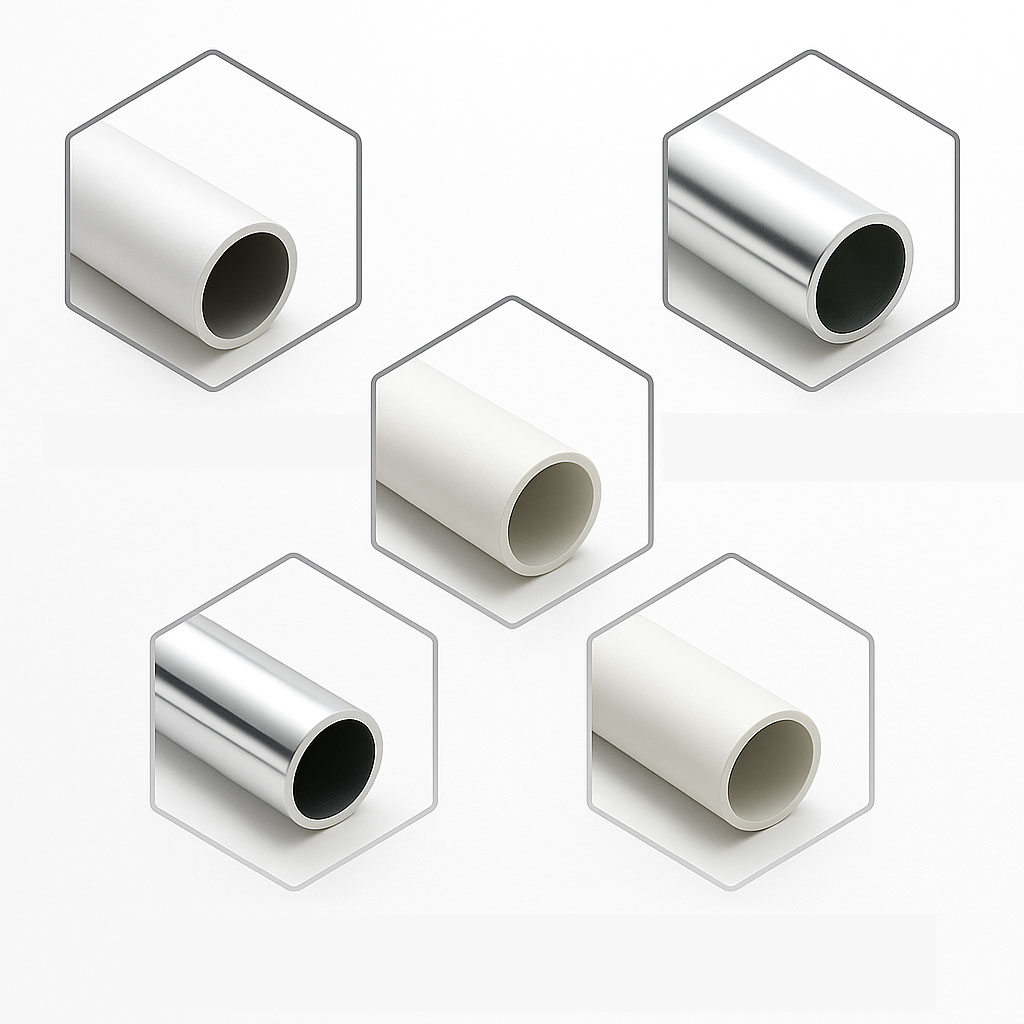

Surface Treatment Options

To improve appearance and durability, 3003 aluminum pipes can be treated in various ways:

- Anodizing: Adds a corrosion-resistant and decorative oxide layer.

- Powder coating: Provides a uniform, colorful, and weather-resistant finish.

- Mechanical polishing: Smooths the surface for aesthetic and functional purposes.

- Brushed or mirror finish: Adds visual appeal in decorative applications.

Why Choose ZGGDMETAL?

ZGGDMETAL has years of experience supplying 3003 aluminum tubes to customers worldwide. Here’s why clients trust us:

- Reliable inventory: We maintain a wide range of sizes in stock for fast delivery.

- Custom services: Need special diameters, finishes, or cutting? We can help.

- Technical support: Our engineers assist in material selection and provide design advice.

- Flexible shipping: We support bulk orders and small-batch customized solutions.

No matter your project size or complexity, ZGGDMETAL is ready to support your needs.

Conclusion

If you’re looking for a cost-effective, corrosion-resistant, and easily workable aluminum tube, 3003 aluminum pipe is a great option. It performs well across different applications and environments, and it’s widely available in various sizes and finishes.

Choosing a trusted supplier like ZGGDMETAL ensures you receive not only top-quality products but also expert service and fast turnaround. Whether you need standard 3003 aluminum tubes or custom solutions, we’re here to help.