Aluminum pipe is widely used in everything from home DIY projects and greenhouse frames to industrial structures and marine components. Its lightweight, corrosion resistance, and high workability make it a go-to choice for professionals and hobbyists alike.

In this guide, we answer three of the most frequently asked questions about aluminum pipe:

- ✅ How to bend aluminum pipe without cracking it

- ✅ How to cut aluminum pipe cleanly and accurately

- ✅ Where to buy high-quality aluminum pipe at competitive prices

1. How to Bend Aluminum Pipe Without Cracking or Flattening

Bending aluminum pipe is simple—but only if done correctly. Aluminum, especially in thinner walls or harder tempers like 6061-T6, can crack or collapse when bent improperly.

Tools You’ll Need:

- Manual or hydraulic pipe bender

- Pipe bending springs or internal mandrel

- Dry sand (optional for thin-walled pipes)

- Propane torch (for mild heating if necessary)

Step-by-Step Bending Guide:

- Choose a bendable alloy: 6063 is easier to bend than 6061-T6.

- Use a proper pipe bender: Match the bender size to your pipe diameter.

- Fill with sand or insert spring: Prevents flattening during bending.

- Apply steady force: Slow, even pressure helps avoid kinks.

- Heat (optional): For thick or hard temper pipes, lightly heat the bend area (~200–300°F) to improve ductility.

Pro Tip: For commercial projects, use mandrel bending machines for precision and repeatability.

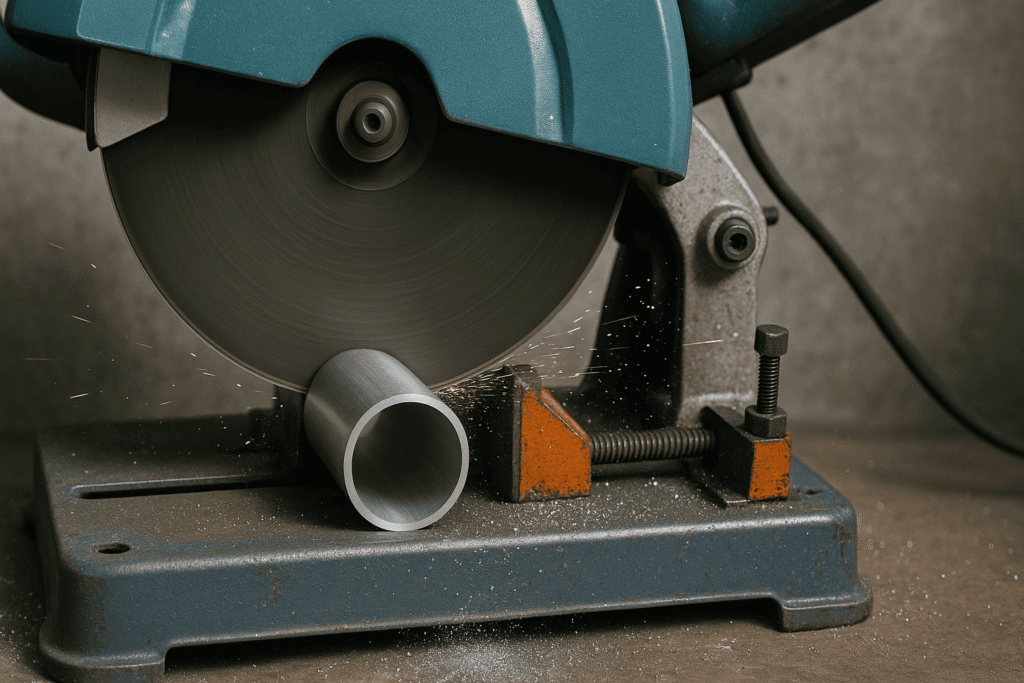

2. How to Cut Aluminum Pipe Cleanly and Safely

Aluminum’s soft nature means it’s easy to cut—but also easy to damage without the right blade or setup.

Recommended Cutting Tools:

| Tool | Best For | Benefits |

|---|---|---|

| Pipe cutter | Thin-wall tubing | Fast, clean edges |

| Miter saw (non-ferrous blade) | Precision cuts | Ideal for multiple pieces |

| Hacksaw | Small DIY jobs | Cheap and easy to control |

| Band saw | Industrial shops | Efficient bulk cutting |

Cutting Tips:

- Always secure the pipe using a clamp or vice.

- Use WD-40 or light oil as a lubricant.

- After cutting, deburr both inner and outer edges to prevent sharpness or fitment issues.

Don’t forget: A clean cut improves the strength and appearance of welded or fitted aluminum joints.

3. Where to Buy Aluminum Pipe (Retail & Wholesale Options)

If you’re wondering where to buy aluminum pipe, here’s how different options compare:

Retail Hardware Stores:

- Pros: Good for immediate needs and small quantities

- Cons: Limited sizes, higher cost, fewer alloy options

Online Marketplaces (Amazon, Home Depot, Alibaba):

- Pros: Convenience and delivery

- Cons: Limited QC, hard to verify material grade

Professional Aluminum Pipe Suppliers:

Best for bulk orders, custom sizes, or guaranteed alloy quality.

Recommended Supplier: ZhongGong Aluminum Co., Ltd.

We supply industrial-grade aluminum pipes in 6061, 6063, 5083 and other alloys, suitable for:

- Marine and structural applications

- Custom tube fabrication

- Heat exchanger or automotive systems

✔️ Mill finish, anodized, or powder-coated

✔️ Customized cutting and bending services

✔️ Global export service with quality certifications

👉 Contact Us Today for a fast quote.