When it comes to lightweight yet durable materials used across manufacturing, aluminium strip stands out as a vital industrial component. Whether you’re designing electrical transformers, HVAC systems, or automotive parts, this versatile material offers the strength, flexibility, and performance industries demand.

This comprehensive guide walks you through what aluminium strip is, the common grades and tempers, its processing methods, and where it’s most effectively used. Let’s explore everything you need to know—in just six minutes.

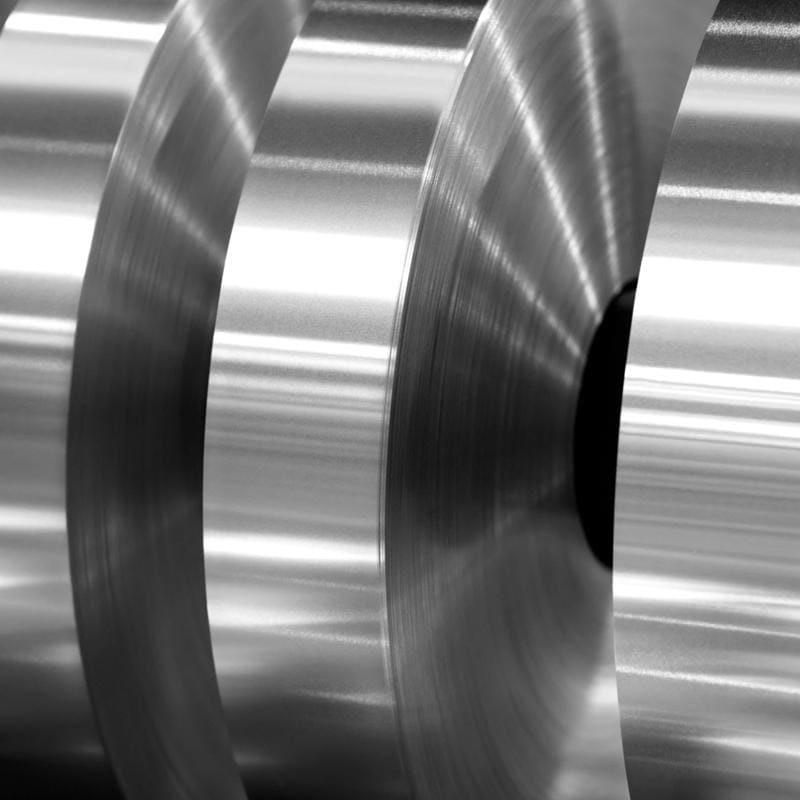

What Is Aluminium Strip?

Aluminium strip, sometimes called aluminum slitting coil or narrow coil, is a flattened piece of aluminium that is slit from wider coils. It is typically produced from cast-rolled or hot-rolled aluminium coils, then processed through cold rolling and slitting to reach specific dimensions.

Available in thicknesses ranging from 0.12mm to 6.0mm, and widths up to 2000mm, aluminium strip is often custom-sized to fit application needs. Depending on how it is annealed, it can be soft and formable or strong and rigid:

- O-temper: Fully annealed, very soft—ideal for deep drawing and bending

- H-temper: Strain-hardened—available in various hardness levels like H18 (full-hard), H24 (semi-hard)

Common Alloy Grades and Their Properties

Aluminium strip is manufactured using a wide range of aluminium alloys. Each grade delivers unique benefits suited for specific industrial tasks:

| Grade | Performance Features | Typical Uses |

|---|---|---|

| 1050 / 1060 / 1100 | Excellent corrosion resistance, great formability, low strength | Storage tanks, cookware, chemical vessels |

| 3003 / 3004 | Good weldability and moderate strength, better than 1xxx | Heat exchangers, building panels, battery casings |

| 5052 | Strong fatigue resistance, marine-grade corrosion resistance | Fuel tanks, auto body panels, boat components |

| 8011 | Superior barrier and sealing properties | Cable shielding, food packaging, HVAC ducts |

Types of Aluminium Strip by Function

Aluminium strip isn’t a one-size-fits-all material. It’s tailored for specific uses depending on the alloy type, surface finish, and thickness. Here are a few specialized categories:

- Transformer Strip: Used in windings thanks to excellent conductivity and thermal performance

- Cable Sheath Strip: Provides EMI protection in electrical cables

- Heat Fin Strip: Maximizes heat dissipation in air conditioners and radiators

- Composite Pipe Strip: Key material in PEX-AL-PEX plumbing

- Decorative Trim Strip: Enhances interiors and building aesthetics

Production Process: How Aluminium Strip Is Made

Manufacturing aluminium strip involves several stages:

- Starting Coil: Hot-rolled or cast-rolled coil

- Cold Rolling: Reduces thickness to precise levels

- Slitting: Coil is slit into narrow strips of desired width

- Annealing: Defines temper (O, H24, H18, etc.)

The slitting process ensures exact dimensions for a wide range of applications. And because aluminium’s conductivity is second only to copper, aluminium strips are increasingly replacing copper strips in electronic components—offering similar performance at a significantly lower cost.

Why Aluminium Strip Is Gaining Popularity Over Copper

With growing demand for cost-efficient and lightweight alternatives, aluminium strip is becoming a mainstream choice in:

- Consumer electronics

- Battery tabs in EVs

- Power transmission components

Its lower density and price, paired with good conductivity, make it an ideal substitute in many applications once dominated by copper.

Industrial Applications of Aluminium Strip

From infrastructure to energy systems, aluminium strip continues to expand its industrial footprint. Some common applications include:

- Electrical Transformers

- Automobile Fuel Tanks and Panels

- Air Conditioner Radiators and Heat Exchangers

- Aluminum-Plastic Composite Pipes (PPR-AL-PPR)

- Curtains, Blinds, and Decorative Paneling

Certain grades such as 1060 and 1100 are chosen for their superior corrosion resistance, while 5052 is ideal for parts requiring both strength and fatigue resistance.

Conclusion

Whether you’re sourcing materials for electronics, transportation, packaging, or construction, aluminium strip is a reliable, cost-effective, and high-performance option. With its diversity in alloy types, processing methods, and applications, it remains a cornerstone material in modern industrial manufacturing.

Looking for a reliable aluminum strip supplier?

zggdmetal, your trusted professional aluminum strip manufacturer in China, provides precision engineering products, custom processing and efficient global shipping services. Let us power your next project.