Introduction: More Than Just a Metal Strip

Though it may seem modest in appearance, aluminum strip is an unsung hero in numerous industries. Whether used in electrical windings, automotive parts, or architectural detailing, it offers an ideal combination of strength, conductivity, and corrosion resistance. This guide dives into the wide-ranging capabilities of aluminum strip, spotlighting its key features, industrial uses, and what you should know before sourcing it for your projects.

What Is Aluminum Strip?

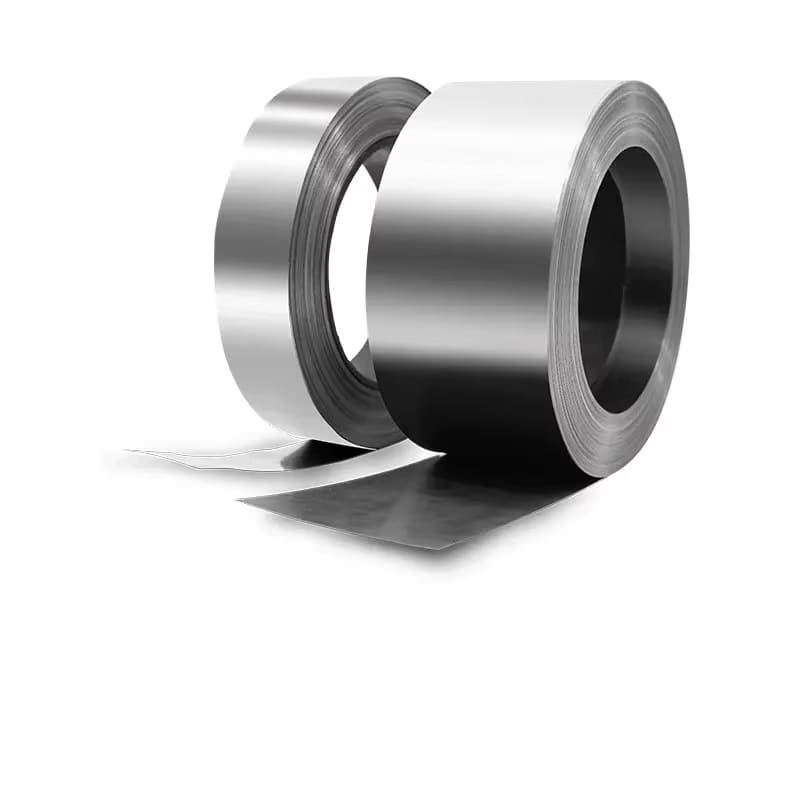

Aluminum strip refers to thin, flat pieces of aluminum cut from larger coils or sheets. These strips vary in width, thickness, and alloy composition, allowing manufacturers to tailor them for specialized applications.

Core Specifications:

- Thickness Range: Typically from 0.1 mm to 3 mm

- Widths: From narrow ribbons to wider bands

- Common Alloys: 1050, 1060, 1100 (for electrical uses); 3003, 5052 (for structural and corrosion-resistant needs); 8011 (for packaging)

- Finishes Available: Mill finish, coated, or anodized, depending on functional and visual requirements

Why Aluminum Strip Is Widely Trusted Across Sectors

The material’s growing relevance is no coincidence. Several standout qualities make aluminum strip a reliable choice across diverse settings:

1.Light but Strong

Aluminum’s impressive strength-to-weight ratio is particularly valuable where load-bearing capacity and weight savings go hand-in-hand—such as in transportation and aerospace.

2.Naturally Resistant to Corrosion

Its self-forming oxide layer shields against environmental damage, making it suitable for long-term outdoor and marine applications.

3.Excellent Electrical and Thermal Conductivity

Especially in electrical systems and heat dissipation components, aluminum strip delivers high performance at a lower cost than copper.

4.Eco-Friendly and Recyclable

It’s fully recyclable, retaining all its properties without quality loss—an advantage that supports sustainability efforts in manufacturing and construction.

Key Applications of Aluminum Strip

Aluminum strip plays a behind-the-scenes role in many familiar and critical products:

1. Power and Electrical Systems

Its conductivity makes it ideal for transformer windings, busbars, and electromagnetic shielding in high-performance circuits.

2. Building and Architectural Elements

Used in ceiling systems, façade trims, window spacers, and rain gutters, aluminum strip supports both function and aesthetics.

3. Automotive and Transport Manufacturing

From fuel tank straps to insulation panels and decorative trims, aluminum strip helps cut vehicle weight while maintaining durability.

4. Packaging Solutions

Aluminum strip is laminated or sealed into caps, bottle closures, and insulation foils in the food, pharmaceutical, and cosmetic sectors.

5. HVAC and Thermal Systems

It is a preferred choice for fins in air conditioning systems and heat exchangers due to its high thermal efficiency.

Choosing the Right Aluminum Strip: What Matters

Not all aluminum strips are created equal. Selecting the right type requires attention to several technical and practical considerations:

1. Alloy and Temper Designation

Different alloys suit different needs. For instance, 1050 and 1060 provide excellent conductivity, while 5052 offers higher strength and resilience. Tempers like H14 or O define hardness and flexibility.

2. Surface Treatment

Choose between raw mill finish, anodizing (for enhanced corrosion resistance), or coating options depending on final use—whether functional or decorative.

3. Dimensional Precision

In automated assembly or cutting applications, tight tolerances are essential to minimize waste and ensure quality.

4. Volume and Customization Requirements

Industrial buyers should consider whether the supplier offers customized slitting widths, coil weights, packaging, or specific treatments suited to their operations.

How It’s Made: Aluminum Strip Production at a Glance

The production process involves:

- Casting and Hot Rolling of aluminum ingots into wide coils

- Cold Rolling to achieve the desired thickness and mechanical properties

- Slitting the coil into precise strip widths

- Annealing/Tempering for strength and ductility adjustments

- Surface Finishing, if required, for appearance or added protection

Market Outlook: Why Demand Keeps Growing

The global market for aluminum strip is experiencing steady expansion, largely due to its use in sustainable technology, electric vehicles (EVs), and lightweight construction materials. As manufacturers seek cost-effective and environmentally sound solutions, aluminum strip is emerging as a key material across both developed and emerging industries.

Conclusion

Aluminum strip is a versatile, performance-driven material that brings together strength, lightness, conductivity, and recyclability. Its role in modern manufacturing continues to grow, offering tailored solutions to evolving industry needs. Whether you’re working on electrical infrastructure, automotive parts, or building components, choosing the right aluminum strip can significantly boost performance and efficiency.

About ZGGDMETAL

ZGGDMETAL is a leading manufacturer and global supplier of high-quality aluminum raw materials, including aluminum strips, aluminum sheets, aluminum coils, aluminum tubes and aluminum bars. Based in China, we focus on providing customized aluminum solutions for industries such as construction, transportation, electrical engineering, HVAC and packaging. ZGGDMETAL is committed to pursuing precision, excellent performance and customer satisfaction, providing standard and customized aluminum products to meet international quality standards. With advanced production equipment and strict quality control, we ensure reliable delivery and satisfactory material quality of aluminum products.