Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

1050 aluminum checkered plate is a high-purity aluminum product with an aluminum content of 99.5%. It features raised patterns such as diamond, five-bar, or lentil designs that provide excellent anti-slip performance. With outstanding corrosion resistance, good formability, and easy weldability, it is widely used in flooring, stair treads, vehicle interiors, decorative panels, and industrial platforms.

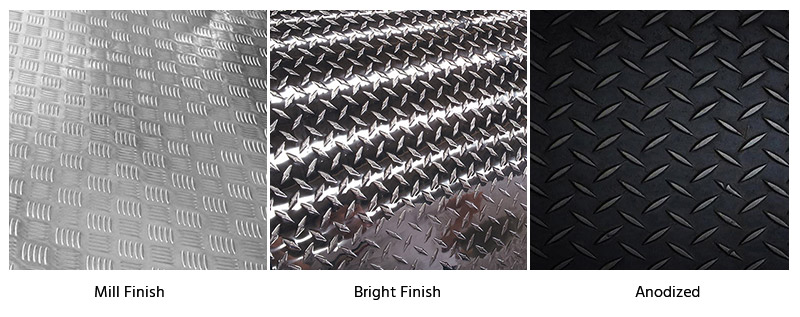

1050 aluminum checkered plate is a type of non-heat-treatable aluminum sheet made from 1050 alloy, which contains about 99.5% pure aluminum. One side of the plate is rolled with raised patterns such as diamond, five-bar, or lentil shapes, giving it excellent anti-slip properties. This product combines lightweight, high corrosion resistance, good formability, and easy weldability.It is commonly supplied in thicknesses from 0.2 mm to 50 mm, with widths up to 2600 mm and lengths up to 16,000 mm. Typical tempers include O, H12, H14, H24, and H112. The surface can be mill finished, polished, anodized, or coated, depending on the application.

Because of its durability and slip-resistant surface, 1050 aluminum checkered plate is widely used for flooring, stair treads, vehicle interiors, decorative panels, and industrial platforms, meeting both functional and aesthetic requirements.

| Alloy | 1050 (Al ≥ 99.5%) |

| Temper | O, H12, H14, H16, H18, H24, H26, H112 |

| Thickness | 0.2 mm – 50 mm (special orders up to 200 mm) |

| Width | 100 mm – 2600 mm |

| Length | 500 mm – 16,000 mm |

| Surface Finish | Mill Finish, Bright/Polished, Anodized, Coated (Powder/Color) |

| Pattern (Tread) | Diamond, Five-bar, Lentil, Small bar |

| Standards | ASTM B209 / ASME SB209, GB/T 20250-2006, GB/T 5584-2009, ISO, RoHS, SGS |

| Applications | Flooring, stair treads, vehicle interiors, decorative panels, industrial platforms, construction, shipbuilding |

| Alloy | Temper | Thickness | Width | Pattern |

|---|---|---|---|---|

| 1050 | O | 0.1 mm | 1000 mm | Checkered |

| 1050 | H14 | 0.2 mm | 1000 mm | Diamond |

| 1050 | H24 | 0.3 mm | 1000 mm | 5-bar |

| 1050 | H18 | 0.4 mm | 1000 mm | Lentil |

| 1050 | O | 0.5 mm | 1000 mm | Small-bar |

| 1050 | H112 | 0.6 mm | 1000 mm | Diamond |

| 1050 | H12 | 0.8 mm | 1000 mm | 2-bar |

| 1050 | H14 | 1.0 mm | 1000 mm | Diamond |

| 1050 | H24 | 1.2 mm | 1000 mm | 5-bar |

| 1050 | O | 1.5 mm | 1000 mm | Lentil |

| Property | Value Range |

|---|---|

| Tensile Strength (σb) | 60 – 100 MPa |

| Yield Strength (σ0.2) | ≥ 20 MPa (O), up to 80 MPa (H18) |

| Elongation (%) | 20 – 35% |

| Hardness (HBW) | 20 – 35 |

| Elastic Modulus (E) | ~70 GPa |

| Density | 2.71 g/cm³ |

| Thermal Conductivity | ~222 W/m·K |

| Electrical Conductivity | ~61% IACS |

| Melting Point | 650 – 660 °C |

1050 aluminum checkered plates are widely used in industries that require lightweight, anti-slip, and corrosion-resistant materials. Thanks to their excellent formability, high ductility, and bright surface finish, they are ideal for:

Flooring and stair treads in factories, workshops, vehicles, and ships for anti-slip safety.

Decorative applications such as wall panels, ceilings, and interior design due to their attractive pattern.

Packaging and storage equipment, where lightweight and easy fabrication are important.

Transportation industry, including truck beds, trailers, and bus flooring.

Industrial equipment and machinery covers, offering both protection and durability.

Architectural applications, such as ramps, platforms, and walkways.

In short, 1050 aluminum checkered plates combine strength with low weight and corrosion resistance, making them a reliable choice for both structural and decorative purposes.

What are the characteristics of 1050 Aluminum Checkered Plate?

What are the characteristics of 1050 Aluminum Checkered Plate?1050 aluminum checkered plate is known for its high aluminum content (≥99.5%) and excellent corrosion resistance. It offers good formability, ductility, and weldability, making it easy to process into different shapes. The patterned surface provides strong anti-slip properties, which is why it is widely used for flooring and stair treads.

Other key characteristics include:

Lightweight & durable – only one-third the weight of steel, yet strong enough for daily wear.

Excellent corrosion resistance – suitable for indoor and outdoor applications.

High reflectivity – bright surface finish makes it attractive for decorative use.

Good conductivity – provides both thermal and electrical conductivity.

Multiple surface patterns – diamond, five-bar, or custom designs for anti-slip and decorative purposes.

Compliance with standards – meets international norms like ASTM, EN, and GB.

In summary, 1050 aluminum checkered plate combines beauty, practicality, and versatility, making it ideal for flooring, decoration, and industrial applications.

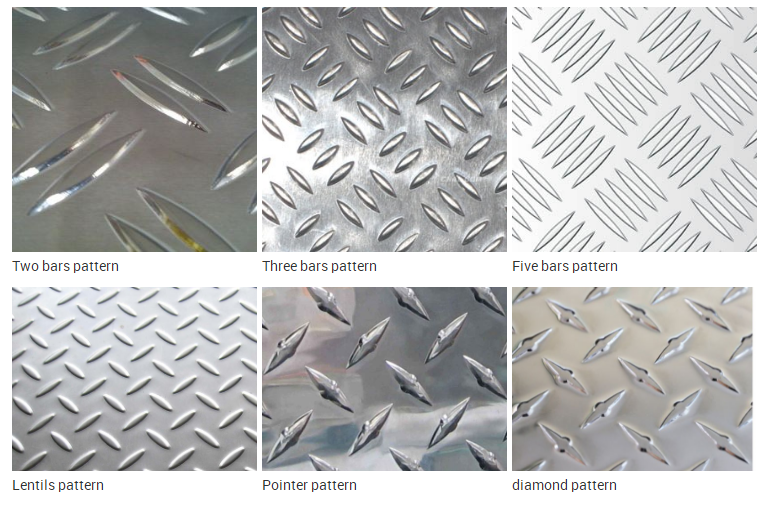

ZGGDMetal offers a variety of patterns for 1050 aluminum checkered plates to meet both functional and decorative needs. Common patterns include:

Diamond Pattern – classic raised diamond shapes for excellent anti-slip performance.

Five-Bar Pattern – long bars providing strong traction for flooring and stair treads.

Lentil Pattern – rounded, small raised shapes for decorative and functional surfaces.

Small-Bar Pattern – compact raised bars ideal for industrial applications and lightweight structures.

These patterns combine safety, durability, and aesthetic appeal, making them suitable for flooring, stair treads, vehicle decks, industrial platforms, and decorative applications.

ZGGDMetal can also provide customized patterns based on your project requirements.