Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

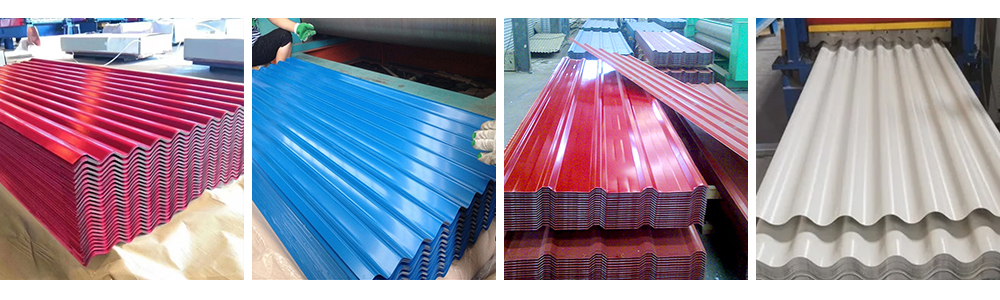

Color Coated Aluminum Roofing Sheet is a lightweight, durable, and corrosion-resistant roofing solution widely used in industrial, commercial, and residential construction. Manufactured from high-quality aluminum alloys such as 1100, 3003, 3105, and 5052, the sheets are coated with advanced paint systems including PE, PVDF, and SMP, ensuring excellent weather resistance and long-lasting color performance.

A Color Coated Aluminum Roofing Sheet is a roofing material made from high-quality aluminum alloy that has been coated with protective paint systems such as PE (Polyester), PVDF (Polyvinylidene Fluoride), or SMP (Silicone Modified Polyester). This surface treatment provides excellent corrosion resistance, weather durability, and long-lasting color performance.

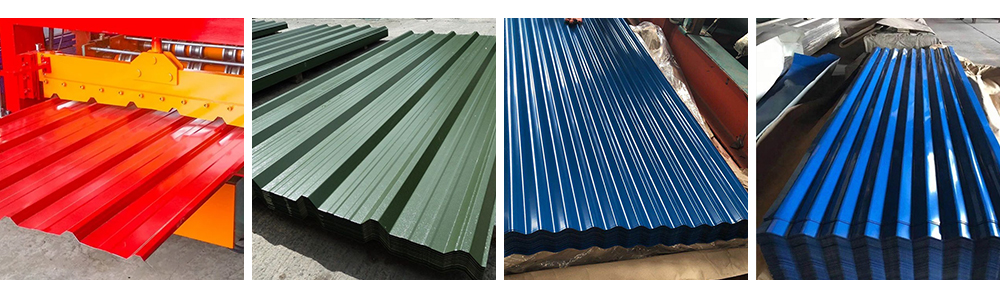

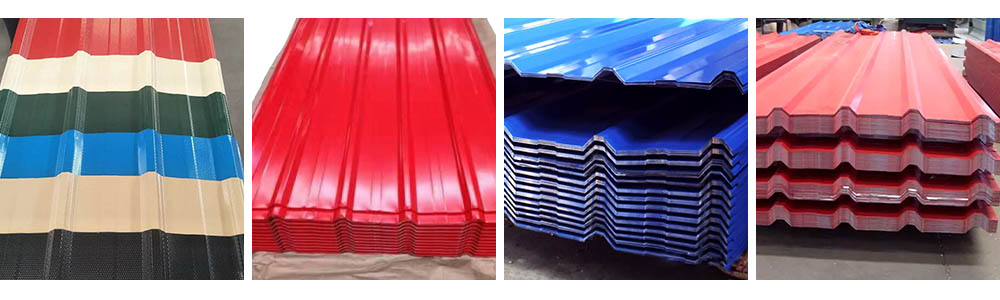

Compared with traditional roofing materials, color coated aluminum sheets are lightweight, easy to install, and highly resistant to rust, UV rays, and extreme weather conditions. They are available in various thicknesses (0.25–1.2 mm), widths (600–1250 mm), and colors, with options for glossy, matte, embossed, or patterned finishes to suit different architectural styles.

Because of their durability and energy efficiency, color coated aluminum roofing sheets are widely used in industrial workshops, warehouses, residential houses, commercial complexes, airports, and decorative facades. With PVDF coatings, they can achieve a service life of 20–25 years, making them a reliable and cost-effective choice for modern roofing solutions.

| Alloy | 1100, 3003, 3105, 5052 |

| Temper | H14, H16, H18, H24, H26 |

| Thickness | 0.25 – 1.20 mm |

| Width | 600 – 1250 mm (commonly 914 / 1000 / 1200 / 1220 mm) |

| Length | 2000 – 6000 mm (custom cut-to-length) or coil form |

| Coating Thickness | PE ≥18 μm; PVDF ≥25 μm |

| Coating Hardness | ≥ 2H (pencil hardness) |

| Weather Resistance | PE coating: 10–15 years; PVDF coating: 20–25 years |

| Surface Finish | Gloss, Matte, Embossed, Wood Grain, Stone Pattern, Customized |

| Color | RAL Standard Colors (White, Grey, Blue, Red, Green, etc.) |

| Standard | ASTM B209, EN 485, JIS H4000, GB/T 3880 |

| Applications | Industrial workshops, warehouses, residential houses, airports, stadiums, commercial buildings, decorative facades |

| Thickness (mm) | Width (mm) | Length (mm) | Alloy | Temper | Surface Finish | Coating Type | Color Options |

|---|---|---|---|---|---|---|---|

| 0.30 | 914 | Coil/3000 | 3003 | H24 | Gloss / Matte | PE | White / Blue |

| 0.40 | 1000 | Coil/6000 | 1100 | H14 | Embossed / Smooth | PE | Grey / Red |

| 0.45 | 1220 | 2440 | 3105 | H16 | Gloss / Matte | PVDF | Green / Black |

| 0.50 | 1000 | Coil/Customized | 5052 | H18 | Matte / Wood Grain | PVDF | RAL Custom |

| 0.60 | 1200 | 3000–6000 | 3003 | H26 | Embossed / Stone | PVDF | White / Silver |

| 0.70 | 1250 | Coil | 3105 | H24 | Gloss / Matte | PE / PVDF | Blue / Red |

| 1.00 | 1220 | 6000 | 5052 | H24 | Gloss / Matte | PVDF | Custom RAL |

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| 1100 | H14 | 110 – 145 | ≥ 95 | ≥ 5 | 28 – 32 |

| 3003 | H16 | 140 – 180 | ≥ 120 | ≥ 4 | 35 – 40 |

| 3003 | H24 | 130 – 170 | ≥ 115 | ≥ 5 | 32 – 38 |

| 3105 | H18 | 150 – 185 | ≥ 125 | ≥ 3 | 38 – 42 |

| 5052 | H24 | 215 – 265 | ≥ 160 | ≥ 7 | 45 – 55 |

| 5052 | H26 | 230 – 280 | ≥ 180 | ≥ 6 | 50 – 60 |

Color Coated Aluminum Roofing Sheets are widely used in construction and architectural projects due to their lightweight, corrosion resistance, and long-lasting surface finish. They are primarily applied in:

Industrial Buildings – factory workshops, warehouses, and logistics centers.

Commercial Projects – shopping malls, office complexes, and exhibition centers.

Residential Housing – roofing, wall cladding, and decorative facades.

Public Infrastructure – airports, railway stations, stadiums, bus terminals.

Interior & Exterior Decoration – ceilings, partitions, and decorative wall panels.

Specialty Applications – cold storage facilities, energy-efficient roofing, and soundproof or fire-resistant building systems.

With customizable thickness, width, coating, and color options, these sheets are ideal for both roofing and wall cladding systems. Thanks to PE and PVDF coatings, they offer service life up to 25 years, making them a reliable choice for modern architecture and durable building solutions.

The main characteristics of Color Coated Aluminum Roofing Sheets include:

Lightweight yet Strong – Aluminum has a high strength-to-weight ratio, reducing structural load while ensuring durability.

Excellent Corrosion Resistance – PE and PVDF coatings provide long-lasting protection against rust, UV rays, moisture, and harsh weather conditions.

Wide Design Flexibility – Available in various thicknesses (0.25–1.2 mm), widths (600–1250 mm), and customizable lengths, with surface finishes such as gloss, matte, embossed, wood grain, and stone patterns.

Long Service Life – PE coatings last 10–15 years, while PVDF coatings can extend lifespan up to 20–25 years.

High Aesthetic Appeal – Offered in RAL standard and custom colors, making them suitable for modern architectural styles.

Good Mechanical Properties – Options in H14, H16, H18, H24, H26 tempers ensure excellent tensile strength, yield strength, and formability.

Energy Efficiency – Reflective surface helps reduce heat absorption, improving building energy performance.

Standards Compliance – Manufactured according to ASTM B209, EN 485, JIS H4000, and GB/T 3880.

ZGGDMETAL is a professional manufacturer specializing in high-quality aluminum roofing sheets with years of experience in the metal industry. We combine advanced production technology with strict quality control to ensure every sheet meets international standards such as ASTM B209, EN 485, and GB/T 3880.

Our roofing sheets are made from premium alloys (1100, 3003, 3105, 5052) and processed with PE or PVDF coatings, guaranteeing excellent corrosion resistance, weather durability, and long service life. With a wide range of thicknesses, sizes, and surface finishes, we provide flexible customization to meet diverse project requirements.

At ZGGDMETAL, we not only focus on product quality but also on service. We maintain sufficient stock for fast delivery, support OEM & ODM customization, and offer competitive pricing for bulk orders. Our technical team provides professional guidance from product selection to application, ensuring that clients receive the most cost-effective roofing solutions.

Choosing ZGGDMETAL means partnering with a reliable factory that delivers durable, energy-efficient, and aesthetically appealing aluminum roofing sheets for industrial, commercial, and residential projects worldwide.