Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

Color Coated Aluminum Sheet is a versatile aluminum material with a pre-applied colored coating on its surface, combining excellent aesthetics with corrosion resistance and durability. It is widely used in construction, signage, home appliances, and transportation industries. The base material is typically high-quality aluminum alloys such as 1000, 3000, or 5000 series, offering good strength, corrosion resistance, and formability.

Color Coated Aluminum Sheet is an aluminum product that features a pre-applied colored coating on its surface. It combines the lightweight strength, corrosion resistance, and formability of aluminum with the aesthetic appeal and durability of a protective coating. Common base alloys include 1000, 3000, and 5000 series, and the sheets come in various thicknesses (0.2–6mm), widths (1000–1500mm), and customizable lengths.

The surface coating types include PE (polyester) for general use, PVDF (fluorocarbon) for superior weather resistance, and HDP (high-durability polyester) for moderate outdoor applications. Coating thickness varies from 4–38μm depending on single, double, or triple layers. These sheets are available in different tempers (O, H12, H14, etc.) and meet international quality standards for adhesion, hardness, impact resistance, and gloss.

Color Coated Aluminum Sheets are widely used in building facades, roofing, ceilings, signage, appliance housings, and vehicle interiors, providing a combination of strength, corrosion protection, and visual appeal.

| Alloy | 1050, 1060, 3003, 3105,5052, 5083 |

| Temper | O, H12, H14, H16, H18, H22, H24 |

| Thickness | 0.2 – 6 mm (common: 0.3, 0.4, 0.5, 0.8, 1.0 mm) |

| Width | 30 – 1600 mm (common: 1000, 1220, 1250, 1500 mm) |

| Length | Customized up to 6500 mm |

| Coating Thickness | Single: 4–20 μm, Double: 25–28 μm, Triple: 30–38 μm |

| Coating Hardness | ≥ 2H |

| Weather Resistance | PE: moderate, PVDF: excellent, HDP: good |

| Surface Treatment | PE (Polyester), PVDF (Fluorocarbon), HDP (High-durability polyester) |

| Color | Customized; available in various RAL or standard colors |

| Standard | ISO 18768-1:2022, GB/T 3880-2006, ASTM B209 (depending on region) |

| Applications | Building facades, roofing, ceiling panels, signage, appliance housings, vehicle interiors |

| Coating Type | Thickness | Width | Length | Alloy (Grade) | Temper (Status) |

|---|---|---|---|---|---|

| PE | 0.2 mm | 30 mm | 1000 mm | 1050 | O |

| PE | 0.25 mm | 50 mm | 1000 mm | 1050 | H14 |

| PE | 0.3 mm | 100 mm | 1000 mm | 1060 | O |

| PE | 0.5 mm | 200 mm | 1000 mm | 3003 | H16 |

| PE | 0.8 mm | 300 mm | 1000 mm | 3105 | H18 |

| PE | 1.0 mm | 500 mm | 1000 mm | 5052 | H24 |

| PVDF | 0.2 mm | 30 mm | 1000 mm | 1050 | O |

| PVDF | 0.5 mm | 100 mm | 1000 mm | 3003 | H14 |

| PVDF | 0.8 mm | 150 mm | 1000 mm | 3105 | H16 |

| PVDF | 1.2 mm | 200 mm | 1000 mm | 5052 | H18 |

| Property | Typical Value / Requirement |

|---|---|

| Tensile Strength (σb) | 130 – 180 MPa (depending on alloy & temper) |

| Yield Strength (σ0.2) | ≥ 85 MPa (for 1000 series) ≥ 120 MPa (for 3000/5000 series) |

| Elongation (A50) | 1% – 15% (varies with temper, O state has higher elongation) |

| Coating Hardness | ≥ 2H |

| Coating Adhesion | No peeling, Grade 1 (ISO/ASTM standard) |

| Impact Resistance | 50 kg·cm, no cracking or peeling |

| T-bend Test | ≤ 2T without coating damage |

| Gloss (60° angle) | Adjustable 10% – 90% |

| Weather Resistance | PE: 8–10 years (indoor/outdoor) PVDF: 20–25 years (outdoor, UV-resistant) |

Lightweight and High Strength: Combines the low density of aluminum with good mechanical strength, making it easy to process and install.

Excellent Corrosion Resistance: The aluminum base and protective coating provide strong resistance to moisture, chemicals, and UV exposure.

Durable Coating Performance: Available in PE, PVDF, and HDP coatings, with coating hardness ≥ 2H, strong adhesion, and long-lasting weather resistance (up to 25 years for PVDF).

Wide Range of Colors and Finishes: Can be supplied in solid colors, metallic, glossy, matte, brushed, or embossed surfaces, meeting different aesthetic needs.

Good Formability: Supports bending, cutting, punching, and deep drawing without cracking or peeling of the coating.

Environmental and Maintenance-Friendly: Non-toxic, recyclable, and easy to clean, reducing long-term maintenance costs.

Compliance with International Standards: Meets ISO, ASTM, and GB standards for mechanical and surface properties.

👉 In summary, Color Coated Aluminum Sheets feature a balance of aesthetics, durability, corrosion resistance, and workability, making them ideal for both indoor and outdoor applications.

Color Coated Aluminum Sheets are widely used across construction, decoration, and industrial applications due to their lightweight, corrosion resistance, and decorative surface. They are mainly used for:

Building and Architecture: exterior facades, curtain walls, roofing, ceiling panels, wall cladding, and insulation systems.

Advertising and Signage: billboards, signboards, display panels, and exhibition stands.

Home Appliances: refrigerator panels, washing machine covers, air-conditioner casings, and kitchen cabinets.

Transportation: vehicle interior panels, decorative trims, and caravan body panels.

Furniture and Interior Design: wall panels, ceilings, and decorative laminates.

Industrial Applications: protective cladding, packaging, and electrical enclosures.

In short, Color Coated Aluminum Sheet is chosen when both strength and appearance are required, making it ideal for durable and aesthetic applications in indoor and outdoor environments.

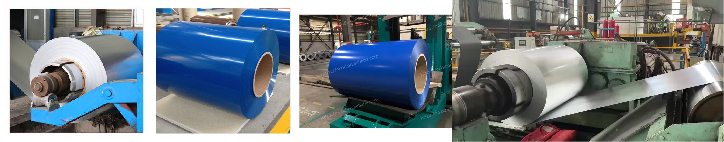

ZGGDMETAL stands out as a reliable manufacturer and supplier of Color Coated Aluminum Sheets with advanced production capabilities and strict quality assurance. We operate modern rolling mills, precision coating lines, and automated slitting machines, ensuring stable performance and consistent surface quality.

Our products cover a wide range of alloys (1000, 3000, 5000 series), tempers, and coatings (PE, PVDF, HDP), with thicknesses from 0.2mm to 6mm and customizable widths up to 1600mm. Whether you need standard sizes or tailor-made solutions, we provide flexible customization in colors, finishes, and coating thicknesses to meet different architectural, decorative, or industrial applications.

We guarantee international standard compliance (ISO, ASTM, GB/T) with coatings that feature hardness ≥2H, strong adhesion, and excellent weather resistance. ZGGDMETAL also provides CNC processing, fast delivery, and professional export packaging to ensure products arrive safely and on time.

By choosing ZGGDMETAL, you benefit from factory-direct pricing, stable long-term supply, global export experience, and dedicated technical support, making us your trusted partner for high-quality Color Coated Aluminum Sheets.