Introduction

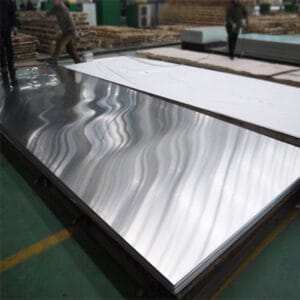

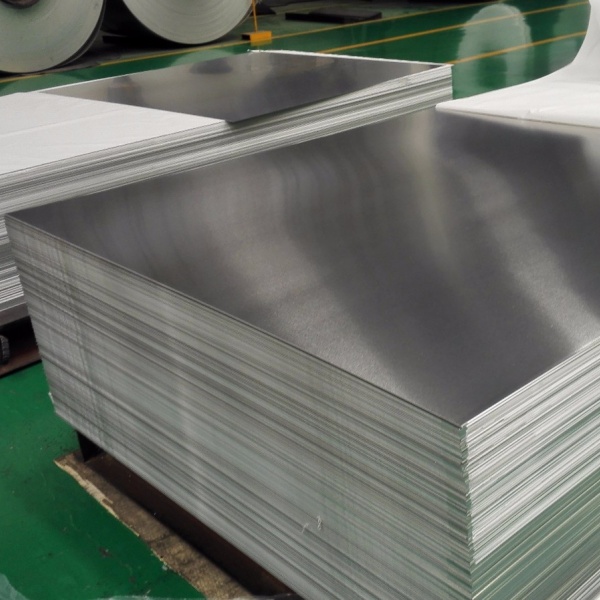

3003 aluminum is one of the most commonly used aluminum alloys in the 3000 series. It is a non-heat-treatable alloy that offers good corrosion resistance, moderate strength, and excellent workability. Thanks to these properties, manufacturers often choose 3003 aluminum for cookware, roofing panels, HVAC systems, storage tanks, and building materials.

This article gives you a full overview of 3003 aluminum—what it is, what it’s made of, how it performs, where it’s used, and how it compares to other alloys.

What Is 3003 Aluminum Made Of?

3003 aluminum is primarily made of pure aluminum mixed with manganese and small amounts of copper. These added elements give it improved strength and corrosion resistance compared to unalloyed aluminum.

Typical chemical composition:

- Aluminum (Al): 97.0%–98.0%

- Manganese (Mn): 1.0%–1.5%

- Copper (Cu): 0.05%–0.2%

- Iron (Fe): ≤ 0.7%

- Silicon (Si): ≤ 0.6%

- Zinc (Zn): ≤ 0.10%

- Other elements: ≤ 0.05%

The small amounts of manganese and copper increase strength without sacrificing formability or corrosion resistance. That’s why 3003 is considered a balanced alloy for both strength and flexibility.

Key Physical Properties

3003 aluminum performs well under a wide range of conditions. It is light, conducts heat and electricity, and is easy to form.

Main physical properties:

- Density: 2.73 g/cm³ (2730 kg/m³)

- Melting point: 650°C

- Thermal conductivity: 193 W/m·K

- Electrical conductivity: About 50% of pure copper

- Poisson’s ratio: 0.33

- Modulus of elasticity (tensile): 68.9 GPa

- Thermal expansion coefficient: 21.5 × 10⁻⁶ /°C

These features make 3003 a smart choice for heat exchangers, radiators, and general-purpose fabrication.

Mechanical Properties and Temper Conditions

3003 aluminum is not heat-treatable. However, it can be hardened through cold working. This means rolling or drawing the material at room temperature to increase strength. Different cold-worked tempers (or conditions) offer different strength levels.

Common temper options and their performance:

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Brinell Hardness |

|---|---|---|---|---|

| O (Annealed) | 95–130 | 40 | 28–30 | 28–40 |

| H12 (1/4 hard) | 115–160 | 65–110 | 10 | 35 |

| H14 (1/2 hard) | 135–180 | 90–145 | 8 | 40 |

| H16 (3/4 hard) | 165–205 | 120–165 | 5 | 47 |

| H18 (Full hard) | 185 | ≥165 | 4 | 55 |

You can choose the right temper depending on your project’s strength and flexibility needs.

How Is 3003 Aluminum Processed?

3003 aluminum is extremely easy to process. It works well in rolling, extrusion, stamping, spinning, and CNC machining. You can cut, drill, mill, or shape it into almost any form without cracking or weakening it.

Welding

3003 aluminum can be welded using TIG, MIG, or arc welding methods. It forms strong joints and resists cracking. This makes it great for pressure vessels, HVAC tubing, and more.

Surface Finishing

To enhance appearance or corrosion resistance, 3003 aluminum can receive a variety of surface treatments:

- Anodizing

- Alodine coating

- Painting

- Electroplating

- Polishing

These finishes make it suitable for both industrial and decorative uses.

Applications of 3003 Aluminum

Thanks to its balanced strength, formability, and rust resistance, 3003 aluminum fits a wide range of everyday and industrial applications.

Cookware and Food Containers

Its excellent resistance to heat and corrosion makes 3003 a safe and long-lasting choice for pots, pans, and storage containers.

Building Materials

Lightweight yet strong, 3003 aluminum is widely used in siding, roofing, garage doors, and wall panels. It is also ideal for decorative trim and cladding.

HVAC Systems

3003 performs well in heating and cooling systems. You’ll find it in radiators, evaporators, and heat exchangers. Due to its great thermal conductivity and corrosion resistance.

Roofing

3003 aluminum panels are used for both flat and sloped roofs. They handle snow, rain, and harsh sunlight without rusting or weakening.

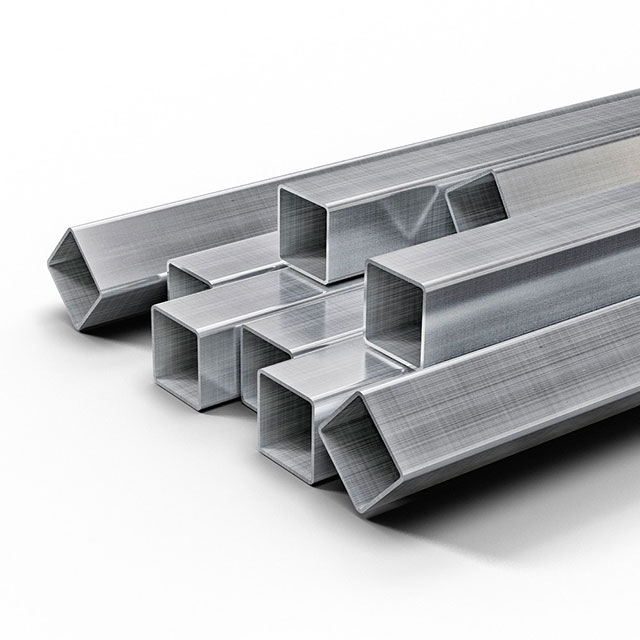

Gas and Water Piping

It offers a good strength-to-weight ratio and doesn’t corrode easily, making it useful for piping systems.

Automotive and Marine

Because its light weight and durability, 3003 is used in body panels, under-hood parts, and marine hardware.

Advantages of 3003 Aluminum

3003 aluminum offers many practical benefits:

- Corrosion resistant: Works well in humid or salty environments

- Lightweight: Easy to handle, ship, and install

- Easy to form: Bends, cuts, and shapes without cracking

- Good weldability: Can be welded by common methods

- Nice surface finish: Looks good after anodizing or painting

- Affordable: Lower cost than many high-strength alloys

These traits make 3003 a go-to material for many budget-sensitive projects.

Limitations to Keep in Mind

While 3003 aluminum has many strengths, it also has a few limits:

- It can’t be heat-treated to increase strength

- Lower fracture toughness than steel or 6000/7000 series alloys

- Not ideal for high-temperature or high-stress environments

If your project needs extremely high strength or structural load-bearing, consider 5052, 6061, or 7075 alloys instead.

How 3003 Compares to Other Aluminum Alloys

Understanding how 3003 stacks up against other popular alloys helps you choose the right one for your needs.

3003 vs. 5052

5052 is stronger and more resistant to marine corrosion, making it better for boats or marine tanks. But 3003 is easier to form and cheaper.

3003 vs. 3004

Both are from the 3000 series, but 3004 has added magnesium. This gives it slightly better strength and formability.

3003 vs. 3105

3105 offers better paint adhesion and surface finishing properties, so it’s often used for siding and pre-painted panels.

Industry Standards and Certifications

3003 aluminum meets several international standards for quality and performance:

- ASTM B209 – Aluminum sheet and plate

- ASTM B210 – Seamless drawn aluminum tube

- ASTM B483 – Aluminum and aluminum-alloy drawn tube for general purposes

These standards ensure consistent quality across different suppliers.

When Should You Use 3003 Aluminum?

Use 3003 aluminum if your project needs:

- Moderate strength

- Good corrosion resistance

- Easy forming and welding

- Lightweight material

- A cost-effective solution

It is ideal for food containers, roofing, ductwork, decorative parts, and HVAC equipment. If you’re unsure whether 3003 is the right fit, compare it with similar alloys based on your project’s key performance needs.

Cost Efficiency

3003 is more affordable than stronger aluminum alloys like 6061 or 7075. It delivers great value for general-use parts, especially where extreme strength is not required. This makes it a smart choice for mass production and industrial use.

Conclusion

3003 aluminum is a strong all-around material. It offers excellent formability, rust resistance, and weldability at a low cost. Whether you need it for cookware, panels, piping, or roofing, it gets the job done without overcomplicating things.

If you’re looking for 3003 aluminum tube, consider working with a reliable aluminum tube supplier like ZGGDMETAL. They offer precision CNC aluminum machining services and provide fast, affordable material pricing information.