Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

The 3003 aluminum strip is a widely used aluminum-manganese alloy known for its excellent corrosion resistance, good formability, and moderate strength. With an aluminum content of over 98%, it is non-heat-treatable but can be strengthened through cold working.

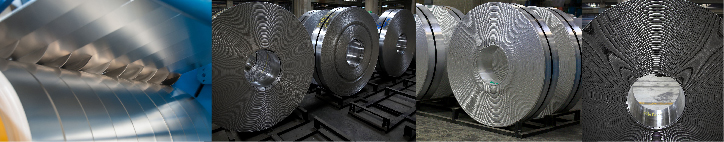

The 3003 aluminum strip is a non-heat-treatable aluminum-manganese alloy strip that combines excellent corrosion resistance with good formability and moderate strength. Containing over 98% aluminum with added manganese, it offers better strength than pure aluminum while maintaining lightweight properties. This alloy is commonly produced in tempers such as O, H14, H18, and H24, with thicknesses ranging from 0.2 mm to 6 mm and widths up to 2650 mm.

3003 aluminum strip can be supplied in various surface finishes including mill finish, polished, brushed, embossed, or color-coated, making it suitable for both functional and decorative purposes. It is widely used in applications such as roofing, cladding, insulation, heat exchangers, automotive parts, and architectural trim. Manufactured under standards like ASTM B209 and ISO 6361, the 3003 aluminum strip ensures durability, versatility, and reliable performance across construction, manufacturing, and industrial projects.

| Alloy | 3003 |

| Temper | O, H22, H24, H14, H16, H26, H18, H28, H112 |

| Thickness | 0.2 mm – 6 mm (0.01″ – 0.24″) |

| Width | 900 mm – 2650 mm (35.4″ – 104″) |

| Length | Up to 6000 mm (customized sizes available) |

| Surface Finish | Mill finish, Polished, Brushed, Hair line, Embossed, Sand blast, Color-coated, Mirror, Checkered, Protective film available |

| Shape | Coil / Roll |

| Standard | ASTM B209 / B210 / B211 / B221 / B483 / B547, AMS 4006 / 4008, ISO 6361, GB/T |

| Packaging | Standard export seaworthy packaging: wooden pallets, eye-to-sky or eye-to-wall coils, with protective film or paper interlayer |

| Applications | Roofing and cladding, Heat exchangers, Automotive parts, Insulation, Decorative trim, Building materials, Industrial manufacturing |

| Thickness (in) | Width / Size (in) | Length (in) / Form | Temper |

|---|---|---|---|

| 0.020″ | 36″ or 48″ | 96″ / 120″ | H14 |

| 0.025″ | 48″ | 120″ | H14 |

| 0.032″ | 36″ / 48″ | 120″ / 144″ / cut-to-order | H14 |

| 0.040″ | 48″ | 120″ / 144″ | H14 |

| 0.032″ | Custom options (1 ft × 1 ft up to 4 ft × 12 ft) | Custom-cut sheet lengths | H14 |

| 0.025″ | 1′ × 1′ up to 4′ × 4′ (common) | Standard cut | H14 |

| 0.190″ | Width 1″ to 4″ available, multiple size options | Blank strip (lengths: 12″, 36″, 72″) | H14 |

| Temper | Tensile Strength (MPa / ksi) | Yield Strength (MPa / ksi) | Elongation (%) | Notes |

|---|---|---|---|---|

| O (Annealed) | ~110 MPa / 16 ksi | ~40 MPa / 6 ksi | 30% | Excellent ductility, easy forming |

| H14 | 130–160 MPa / 22 ksi | ~145 MPa / 21 ksi | 3–5% | Most common temper, moderate strength |

| H16 | ~150–170 MPa | ~160 MPa | 3–4% | Higher strength, reduced ductility |

| H18 | 185–200 MPa / 29 ksi | ~186 MPa / 27 ksi | 2–3% | Hard temper, strong but less formable |

| H22 | ~125 MPa | ~81 MPa | 8–10% | Balance of strength and elongation |

| H24 | ~150 MPa | ~120 MPa | 5–8% | Medium strength, better ductility than H18 |

| H26 | ~170 MPa | ~150 MPa | 3–5% | Higher strength, limited bending |

| H28 | ~200 MPa | ~180 MPa | 2–3% | Very high strength, minimal elongation |

The 3003 aluminum strip is an aluminum-manganese alloy known for its excellent corrosion resistance, especially in atmospheric and humid environments. It has moderate strength, higher than pure 1100 aluminum, while still maintaining lightweight properties. Being non-heat-treatable, it gains strength mainly through cold working and is available in tempers such as O, H14, H18, and H24.

Another key characteristic is its good formability and weldability, which makes it easy to bend, stamp, or fabricate into complex shapes. It also offers high thermal and electrical conductivity, making it suitable for heat exchangers and electrical applications. The alloy can be supplied with different surface finishes such as mill finish, polished, brushed, embossed, or color-coated, enhancing both functional and decorative uses.

Overall, 3003 aluminum strip combines durability, versatility, and cost-effectiveness, making it widely used in construction, automotive, packaging, and industrial manufacturing.

The 3003 aluminum strip is valued for its excellent corrosion resistance, good formability, and lightweight strength, making it suitable for a wide range of applications. It is commonly used in roofing and cladding panels, building insulation, and decorative trims in construction. In the automotive and transportation industries, it is applied to heat exchangers, fuel tanks, and body panels due to its ability to withstand moisture and chemical exposure.

Additionally, 3003 aluminum strip is often chosen for air conditioning and refrigeration tubing, solar collectors, and kitchen utensils, where durability and thermal conductivity are important. Its availability in various tempers and surface finishes also makes it a popular choice for sign boards, nameplates, packaging, and electrical housings. With compliance to standards such as ASTM and ISO, the 3003 aluminum strip ensures reliable performance across industrial, architectural, and decorative applications.