Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

8011 aluminum foil is an 8xxx series aluminum alloy widely used in packaging, household, and industrial applications. It contains 0.50–0.90% Si and 0.60–1.00% Fe, giving it excellent corrosion resistance, high strength, and good formability.

| Alloy Grade | 8011 |

| Thickness Range | 0.0055 – 0.2 mm (5.5–200 μm), special orders up to 0.5 mm |

| Width Range | 100 – 1600 mm (common: 150–500 mm) |

| Temper | O (soft), H12, H14, H16, H18, H19, H22, H24, H26, H28, F |

| Surface Finish | Mill finish, embossed, lacquered, colored coating, hydrophilic, bright/matte combination, double bright |

| Standards | ASTM B479, AMS-QQ-A-1876, GB/T 3198-2010, ASME SB479 |

| Shape | Jumbo roll, small roll, sheet |

| Payment Terms | T/T, L/C |

| Applications | Food packaging (household foil, baking wrap, flexible pouches), pharmaceutical packaging (blister, cold-form), bottle caps & container lids, heat exchanger fins, insulation, decorative and labeling uses |

| Alloy – Temper | Thickness | Width |

|---|---|---|

| 8011 – O (Soft) | 0.0055 mm – 0.2 mm (5.5–200 μm) | 200 mm – 1600 mm |

| 8011 – H14 | 0.006 mm – 0.2 mm (6–200 μm) | 100 mm – 1500 mm |

| 8011 – H16 | 0.006 mm – 0.2 mm | 100 mm – 1500 mm |

| 8011 – H18 | 0.006 mm – 0.2 mm | 100 mm – 1600 mm |

| 8011 – H19 | 0.008 mm – 0.025 mm (8–25 μm) | 150 mm – 500 mm |

| 8011 – H22 / H24 / H26 / H28 | 0.01 mm – 0.2 mm | 100 mm – 1600 mm |

| 8011 – F (As fabricated) | 0.006 mm – 0.5 mm | 100 mm – 1600 mm |

| Element | Content (%) |

|---|---|

| Silicon (Si) | 0.50 – 0.90 |

| Iron (Fe) | 0.60 – 1.00 |

| Copper (Cu) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.20 |

| Magnesium (Mg) | ≤ 0.050 |

| Chromium (Cr) | ≤ 0.050 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.080 |

| Aluminum (Al) | Remainder |

| Temper | Tensile Strength (MPa) | Elongation (%) | Yield Strength (MPa) |

|---|---|---|---|

| O (Soft) | 45 – 110 | ≥ 12 | ≤ 60 |

| H14 | 120 – 150 | 2 – 5 | 110 – 130 |

| H16 | 140 – 165 | 1 – 3 | 130 – 150 |

| H18 | 150 – 185 | ≤ 2 | 140 – 170 |

| H22 / H24 | 120 – 160 | 2 – 5 | 110 – 150 |

| H26 / H28 | 140 – 185 | 1 – 3 | 130 – 170 |

8011 aluminum foil is an 8xxx series alloy characterized by a balance of strength, corrosion resistance, and formability. Its main features include:

Excellent barrier properties – effectively blocks light, moisture, gases, and contaminants

Good corrosion resistance – stable against most food, chemical, and environmental conditions

High strength-to-weight ratio – lightweight yet strong, especially in H-series tempers

Good formability – suitable for deep drawing, stamping, and sealing processes

Wide temper range – from soft (O) for maximum ductility to hard (H18/H26) for higher strength

Surface versatility – available in mill finish, embossed, lacquered, colored, hydrophilic, bright/matte finishes

Compliance with standards – meets ASTM B479, AMS-QQ-A-1876, GB/T 3198-2010

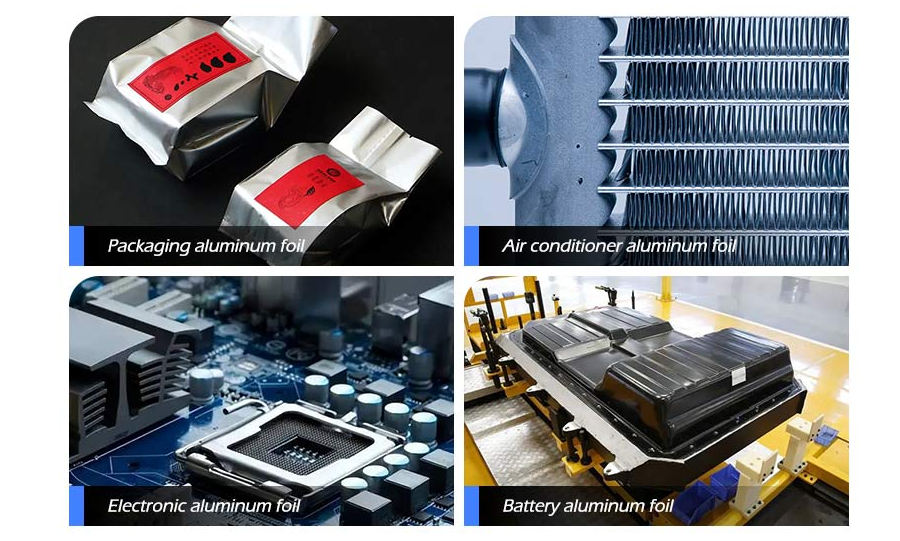

8011 aluminum foils are widely used in packaging, sealing, and heat exchange applications due to their corrosion resistance, barrier properties, and formability.

Typical uses include:

Food packaging – flexible pouches, household foil, baking and cooking wraps

Pharmaceutical packaging – blister packs, cold-formed foils, and strip packs

Bottle caps & container lids – especially for beverages, dairy, and cosmetics

Heat exchangers – fin stock for air conditioners and radiators, often with hydrophilic coating

Industrial insulation – moisture and thermal barriers in construction and cable wrapping

Decorative and labeling materials – colored or lacquered foils for branding and product protection

Its combination of lightweight, strength, and surface treatment options makes 8011 aluminum foil suitable for both consumer and industrial markets.

Choosing ZGGDMETAL as your aluminum foil partner offers several strategic advantages when compared with general market suppliers:

Comprehensive Product Range

While many suppliers specialize in a single category (e.g., only household foil or industrial fin stock), ZGGDMETAL manufactures and supplies a full aluminum product portfolio — from aluminum foil (8011, 1235, 3003, etc.) to plates, coils, tubes, profiles, and color-coated products. This breadth allows buyers to consolidate sourcing, reducing supplier management complexity.

Manufacturing Capability & Quality Control

Unlike trading companies that rely on subcontracted production, ZGGDMETAL operates its own advanced manufacturing facilities in Foshan, Guangdong, ensuring control over production schedules, process stability, and quality inspection. Their operations follow ISO 9001 and relevant ASTM / GB standards, matching or exceeding the quality assurance systems found in leading exporters such as Chalco and HTMM.

Customization Flexibility

Many commodity foil suppliers offer only standard thicknesses and widths. ZGGDMETAL supports custom temper, thickness, width, and surface treatment (e.g., mill finish, lacquered, embossed, hydrophilic coating) — comparable to high-end specialty foil makers like SAM or Lichen Aluminum, but with shorter lead times for custom orders.

International Compliance & Application Expertise

ZGGDMETAL’s aluminum foils meet food-contact safety certifications and are compliant with ASTM B479, GB/T 3198-2010, making them suitable for food, pharmaceutical, and industrial applications. This is critical for buyers in regulated markets, where some low-cost suppliers cannot provide full traceability or documentation.

Supply Chain Reliability

The company’s 15+ years of industry experience, global logistics network, and steady raw material sourcing help maintain price stability and timely delivery — advantages over smaller or newer suppliers whose supply chains are less robust.

Technical Support & Partnership Approach

ZGGDMETAL offers technical consultation, packaging design input, and after-sales service, enabling a true partnership rather than a transactional relationship — a level of support often absent with purely price-driven suppliers.