ZGGDMETAL 6063 Aluminum Tube Procurement Guide

ZGGDMETAL provides 6063 aluminum tube products with sufficient stock and fast delivery, supporting multiple specifications customization and bulk ordering. All products comply with international standards such as AMS, ASTM, EN, and strict quality inspection to ensure stable and reliable performance.

- Standard export orders are usually shipped within 7 working days after confirmation, including customs clearance and transportation processes.

- As an aluminum tube manufacturer with large-scale extrusion and finishing capabilities, ZGGDMETAL can help you reduce procurement costs by up to 15% without compromising product quality.

- Standard sizes are all equipped with ready-made molds, without additional mold fees, greatly saving customization costs.

- Whether it is conventional size, special wall thickness, or surface treatment requirements, we can provide personalized solutions according to project needs.

ZGGDMETAL has a large inventory of 6063 aluminum tubes, which can be supplied immediately and delivered quickly. For more product information, please refer to the 6063 aluminum tube stock list.

ZGDDMETAL 6063 Aluminum Tube Specifications

| Alloy |

6063 |

| Temper |

T4, T5, T6,T52 |

| Equivalent Name |

EN AW‑6063(AlMg0.7Si),UNS A96063,A6063,J454 |

| Outer Diameter |

0.08″ – 17.72″(2.00 mm – 450 mm) |

| Wall Thickness |

0.008″ – 0.984″(0.20 mm – 25.00 mm) |

| Length |

3.94″ – 590.55″(100 mm – 15,000 mm ) |

| Shape |

Round,Square,Reactangular,oval(👉Click for details) |

| Production process |

Extrusion,cold drawing |

| Surface Finish |

Anodized, Powder Coated, Electrophoresis, Mechanical Polishing, Brushed |

| Standard |

ASTM B221,ASTM B241,EN 755‑2/9,ISO 6362‑2,DIN 1748,AMS 4156,AA 6063(👉Click for details) |

| Delivery Condition |

Seven working days after order confirmation |

| Packaging |

Plastic film, anti-rust paper, wooden cases, steel racks |

| Applications |

Door and window frames, curtain wall support structures, balcony guardrails, explosion-proof pipes and connectors on tank trucks, etc. |

ZGDDMETAL 6063 T52 Round Tube Stock List

Stock information is updated in real time, please contact us for the latest information and quotation.

Quick Quote.

| Description |

OD(in) |

Wall Thickness(in) |

| 6063‑T52‑RT‑1.000‑0.125 |

1.000″ |

0.125″ |

| 6063‑T52‑RT‑1.250‑0.065 |

1.250″ |

0.065″ |

| 6063‑T52‑RT‑1.250‑0.090 |

1.250″ |

0.090″ |

| 6063‑T52‑RT‑1.250‑0.125 |

1.250″ |

0.125″ |

| 6063‑T52‑RT‑1.500‑0.065 |

1.500″ |

0.065″ |

| 6063‑T52‑RT‑1.500‑0.090 |

1.500″ |

0.090″ |

| 6063‑T52‑RT‑1.500‑0.125 |

1.500″ |

0.125″ |

| 6063‑T52‑RT‑2.000‑0.083 |

2.000″ |

0.083″ |

| 6063‑T52‑RT‑2.000‑0.125 |

2.000″ |

0.125″ |

| 6063‑T52‑RT‑3.000‑0.083 |

3.000″ |

0.083″ |

| 6063‑T52‑RT‑3.000‑0.125 |

3.000″ |

0.125″ |

| 6063‑T52‑RT‑4.000‑0.083 |

4.000″ |

0.083″ |

| 6063‑T52‑RT‑4.000‑0.188 |

4.000″ |

0.188″ |

| 6063‑T52‑RT‑6.000‑0.125 |

6.000″ |

0.125″ |

| 6063‑T52‑RT‑6.000‑0.188 |

6.000″ |

0.188″ |

ZGDDMETAL 6063 T52 Square/Rectangular Tube Stock Specification Sheet

| Description |

Size |

Wall Thickness(in) |

| 6063‑T52‑ST‑1.000×1.000‑0.062 |

1.00″ × 1.00″ |

0.062″ |

| 6063‑T52‑ST‑1.000×1.000‑0.125 |

1.00″ × 1.00″ |

0.125″ |

| 6063‑T52‑ST‑1.250×1.250‑0.125 |

1.25″ × 1.25″ |

0.125″ |

| 6063‑T52‑ST‑1.500×1.500‑0.125 |

1.50″ × 1.50″ |

0.125″ |

| 6063‑T52‑RT‑1.000×1.500‑0.125 |

1.00″ × 1.50″ |

0.125″ |

| 6063‑T52‑ST‑2.000×2.000‑0.125 |

2.00″ × 2.00″ |

0.125″ |

| 6063‑T52‑ST‑2.000×2.000‑0.188 |

2.00″ × 2.00″ |

0.188″ |

| 6063‑T52‑ST‑3.000×3.000‑0.125 |

3.00″ × 3.00″ |

0.125″ |

| 6063‑T52‑ST‑3.000×3.000‑0.188 |

3.00″ × 3.00″ |

0.188″ |

| 6063‑T52‑RT‑2.500×1.250‑0.125 |

2.50″ × 1.25″ |

0.125″ |

👉If the standard specifications listed above do not meet your requirements, you can contact us directly to obtain customized product information.

Quick Quote.

ZGGDMETAL 6063 aluminum tube Chemical Composition

| Si |

0.20–0.60% |

| Mg |

0.45–0.90% |

| Fe |

≤ 0.1% |

| Mn |

≤ 0.1% |

| Cr |

≤ 0.1% |

| Cu |

≤ 0.1% |

| Ti |

≤ 0.1% |

| Zn |

≤ 0.1% |

| AL |

Balance |

ZGGDMETAL 6063 Aluminum Tube Mechanical Properties

| Property |

Unit |

6063-T6 |

6063-T52 |

| Tensile Strength, Ultimate |

MPa (ksi) |

190–240 MPa (28–35 ksi) |

≥140 MPa (≥20 ksi) |

| Tensile Strength, Yield (0.2%) |

MPa (ksi) |

≥160 MPa (≥23 ksi) |

≥97 MPa (≥14 ksi) |

| Elongation at Break (in 50 mm) |

% |

8–10% |

10–12% |

| Modulus of Elasticity |

GPa (psi) |

68.9 GPa (10,000 ksi) |

68.9 GPa (10,000 ksi) |

| Hardness, Brinell (HB) |

– |

70–75 |

60–65 |

| Shear Strength |

MPa (ksi) |

~140 MPa (20 ksi) |

~100 MPa (14 ksi) |

| Fatigue Strength (Reverse Stress) |

MPa (ksi) |

69 MPa (10 ksi) |

Not typically listed |

| Density |

g/cm³ (lb/in³) |

2.70 (0.0975) |

2.70 (0.0975) |

Comparison of heat treatment states

| State |

Characteristics |

| T1 / T4 / T5 |

Medium strength, suitable for bending or complex shape processing |

| T6 / T52 |

High strength (tensile strength of about 280MPa), suitable for load-bearing and fatigue-resistant design |

6063 Aluminum Tube International Standards Comparison Table

| Region/Country |

Standard Name / Code |

Description |

| USA |

ASTM B221 / ASTM B241 |

Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes |

| SAE AMS-QQ-A-200/9 |

Aluminum Alloy, 6063, Extrusions |

| SAE AMS-4156 (T6 Tube) |

High Strength, Aerospace Grade Extruded Tube |

| Europe (EN) |

EN 573-3 / EN 755-8 |

Chemical composition / Mechanical properties for extruded tubes |

| Germany |

DIN 3.3206 / DIN EN 755-2 |

Standardized under European EN norms |

| UK |

BS EN 755-8 |

Specification for aluminum and aluminum alloys – extruded tubes |

| Japan |

JIS H 4100: A6063 |

Japanese standard for extruded aluminum products |

| China |

GB/T 3191 / GB/T 6892 |

National standards for extruded aluminum profiles and tubes |

| ISO |

ISO 6361-2 / ISO 6361-4 |

Wrought aluminum alloy extruded tubes – mechanical properties |

| Canada |

CSA B221 |

Aluminum alloy extrusions (based on ASTM B221) |

| Russia (GOST) |

GOST 22233-2001 |

Extruded aluminum alloys, structural applications |

ZGGDMETAL 6063 Aluminum Tube Advantages

- Good surface treatment performance

- Excellent corrosion resistance

- Good formability and extrudability

- Medium strength

- Strong weldability

- Lightweight

Applications of ZGGDMETAL 6063 Aluminum Pipe

- Window frames, door frames, curtain wall profiles, handrails, sunshade structures, decorative components;

- bus frames, bicycle racks, trailer structures, shelves, roof racks;

- piping systems, structural supports, heat exchanger housings, equipment frames, slide rails;

- furniture frames, lamp supports, exhibition stands, shelves, lighting housings;

- instrument housings, supporting structures, ventilation ducts, aircraft non-load-bearing structures;

- yacht handrails, boat railings, outdoor camping stands, solar stands

Application Recommendations

| T6 state |

suitable for scenarios requiring higher strength and certain structural rigidity, such as load-bearing support, mechanical components, etc. |

| T5 / T52 state |

has better formability and surface treatment performance, suitable for decorative profiles, heat dissipation structures, power busbars, building exterior accessories, etc. |

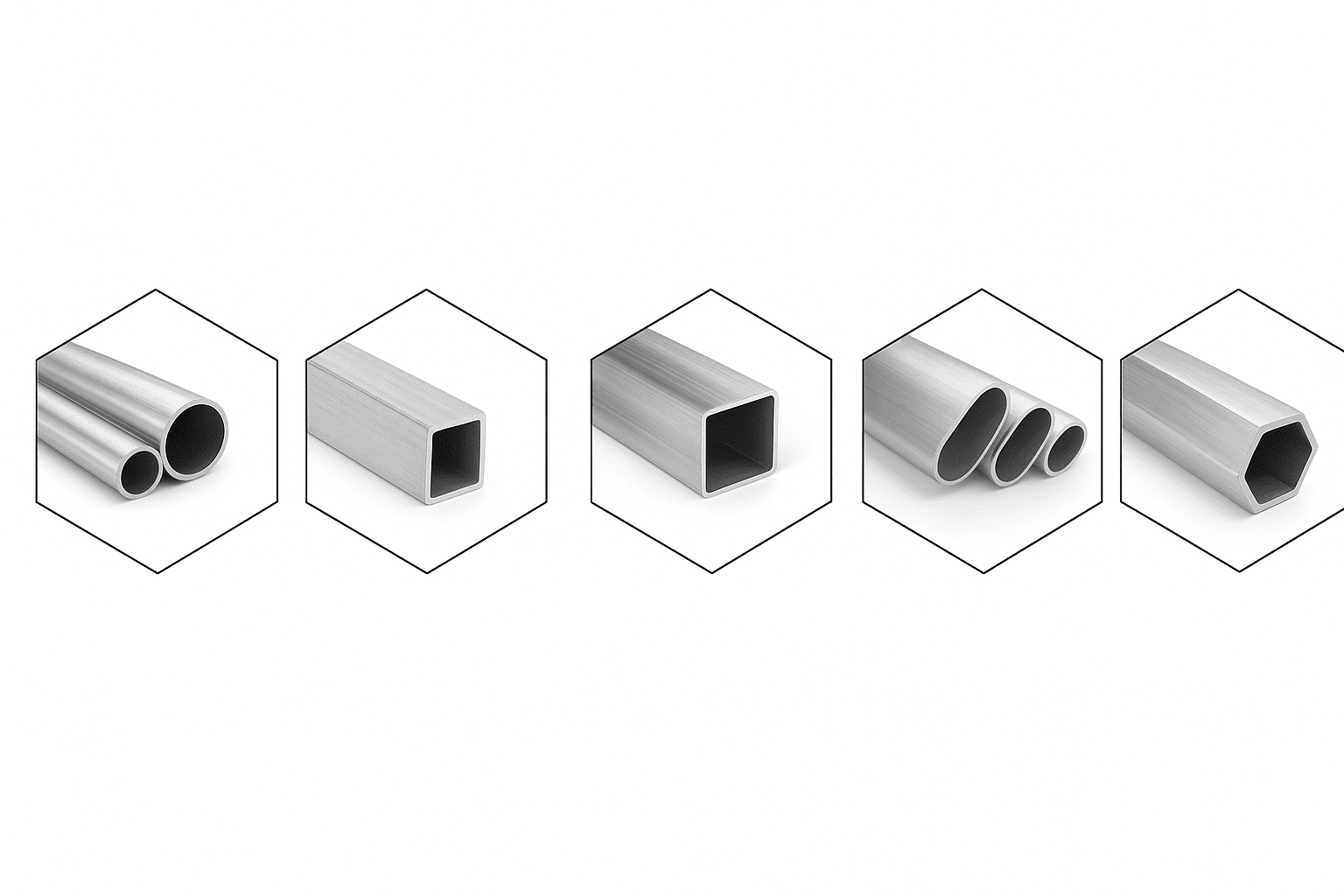

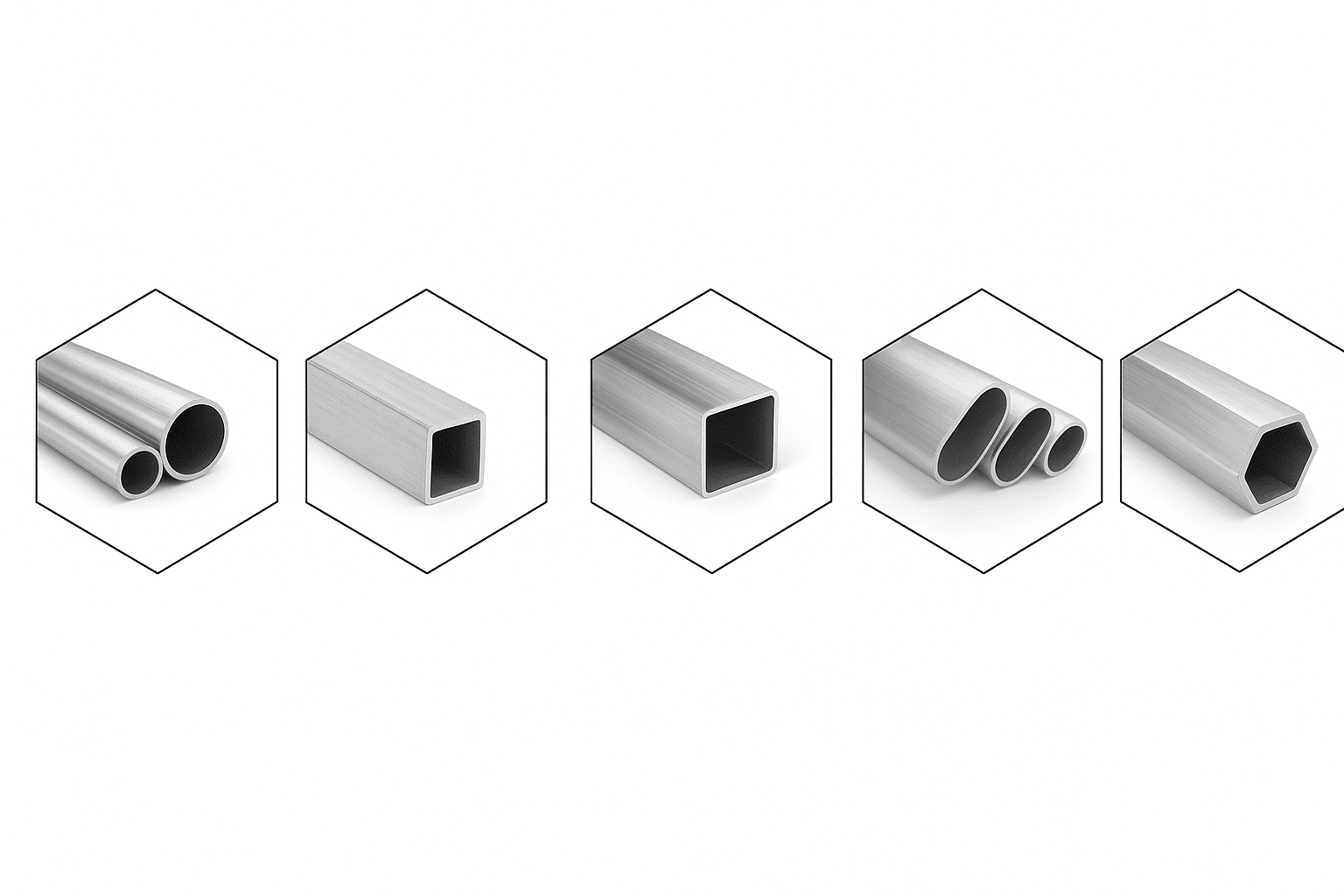

What shapes of 6063 aluminum tubes can ZGGDMETAL produce?

ZGGDMETAL can produce 6063 aluminum tubes in various shapes, including 6063 aluminum round tube, 6063 aluminum square tube, 6063 aluminum rectangular tube, and 6063 aluminum oval tube. Quick Quote.

Does ZGGDMETAL provide CNC machining services for 6063 aluminum tubes?

Yes, ZGGDMETAL provides a full range of precision CNC machining and secondary machining services to meet various manufacturing needs of 6063 aluminum tubes. Our machining capabilities include:

- Precision cutting and drilling

- CNC milling and turning

- Controlled wall thickness reduction

- Laser cutting and surface etching

- TIG/MIG welding and heat treatment

- Complex machining and custom forming

- Tube bending, forming and slotting

We are equipped with advanced CNC equipment, all controlled by an experienced operation team, to ensure the dimensional accuracy, high surface finish and short lead time of 6063 aluminum tubes, which can meet the high quality requirements of standard and custom parts. 👉 Quick Quote!

Why choose ZGGDMETAL as your 6063 aluminum tube supplier?

As a professional 6063 aluminum alloy tube manufacturer, ZGGDMETAL has leading production facilities and automated manufacturing systems to ensure efficient production and stable quality. Our core equipment includes:

- Double-action reverse extruder

- Gas jet rapid heating furnace

- Hot demoulding device

- Infrared continuous temperature monitoring system

- Precision control water vapor quenching equipment

- Horizontal fourteen-roll straightening system

- High-precision cutting and rebound detection platform

In addition, ZGGDMETAL has fully introduced intelligent and automated production systems, which greatly improves the processing efficiency of batch and customized orders. The system has the following advantages:

- Shorten production cycle

- Achieve real-time quality control

- Reduce unit cost

- Increase delivery response speed

Whether you need standard-sized 6063 aluminum tubes or Custom aluminum pipe, ZGGDMETAL can provide you with fast response, professional support and flexible delivery to help your project go smoothly.