Introduction: Why Aluminum is Crucial for Electrical Applications

Aluminum stands out as a key material in the electrical industry, known for its lightweight, high electrical conductivity, and corrosion resistance. Unlike traditional copper, electrical grade aluminum offers a weight advantage, reducing the overall system mass while maintaining efficient power transfer. This makes it ideal for renewable energy, electric vehicles (EVs), and smart grids, where energy efficiency and sustainability are paramount. In this guide, we’ll explore the main aluminum products used in electrical applications, their benefits, and essential selection tips, helping you make smarter purchasing decisions.

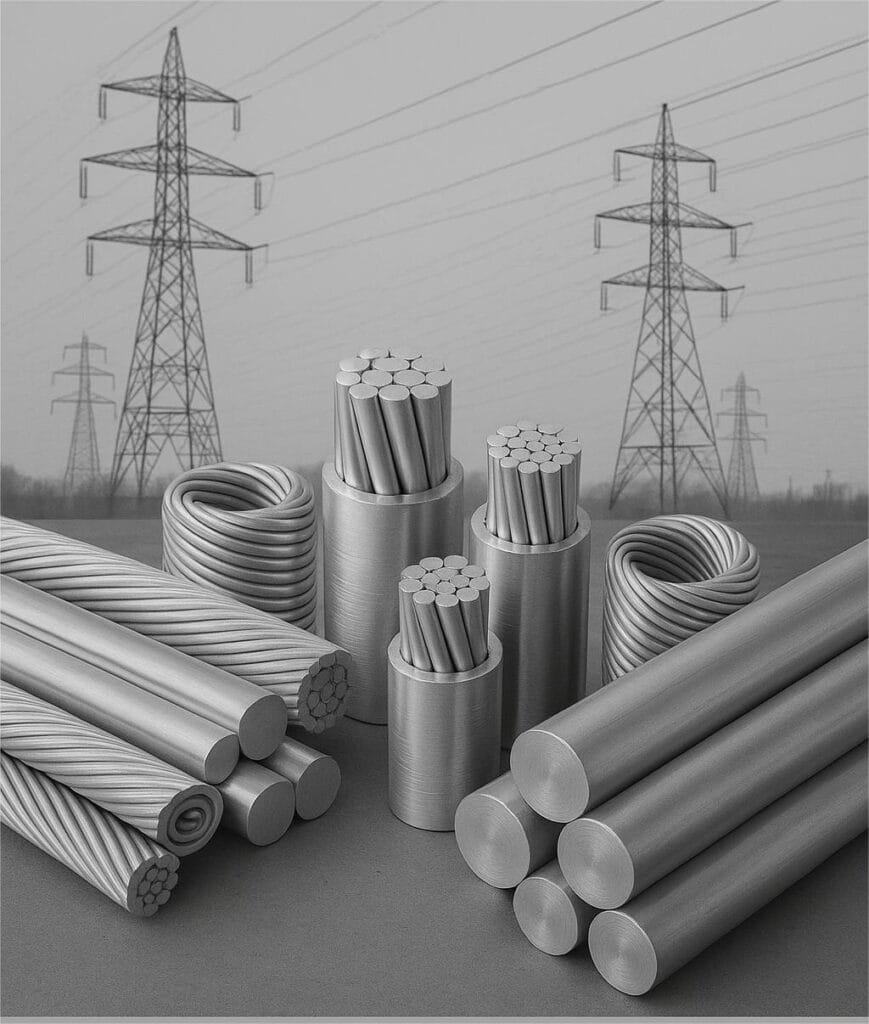

1.Major Electrical Applications of Aluminum

- Power Transmission and DistributionAluminum busbars and high conductivity aluminum wires are widely used in power transmission and distribution systems. Compared to copper, aluminum weighs roughly 30% as much while delivering about 61% of its conductivity, making it a cost-effective choice for overhead power lines and substation equipment. This lightweight advantage reduces the mechanical stress on power structures and lowers overall system costs.

- Electric Vehicles and Renewable EnergyIn electric vehicles (EVs) and renewable energy systems, lightweight aluminum plays a critical role. It not only reduces the overall vehicle weight but also enhances battery and motor efficiency. Aluminum battery enclosures and motor housings are widely used for their superior strength and thermal management properties, helping increase EV range and energy efficiency.

- Electronics and ComponentsAluminum heat sinks, capacitor cases, and electrical enclosures are essential in electronics, where efficient heat dissipation and durability are crucial. Aluminum’s high thermal conductivity and flexibility make it a preferred material for cooling systems in LED lighting, power modules, and amplifiers.

2.Common Aluminum Product Types and Technical Specifications

- Aluminum sheets and coils are fundamental in electrical applications, commonly used for cable armor, busbar wrapping, and heat sinks. Key grades include 1060, 1100, 3003, and 5052, each offering distinct conductivity, strength, and corrosion resistance for specific applications.

- Aluminum profiles are widely used in power systems for busbars, battery cases, and junction boxes. Their excellent strength and versatility in complex extrusions make them suitable for various electrical structures.

- Aluminum Foil&Electrical aluminum foil is essential for capacitors, battery tabs, and cable shielding. Its high conductivity and flexibility make it a critical component in modern electronics.

Key Advantages of Aluminum in Electrical Applications

- High Conductivity: Aluminum offers excellent electrical conductivity, critical for power systems.

- Lightweight Structure: About one-third the weight of copper, reducing overall system mass.

- Corrosion Resistance: Provides durability in harsh environments.

- Cost Efficiency: Lower raw material costs and easier processing reduce production expenses.

- Recyclability: 100% recyclable, supporting sustainable manufacturing practices.

- Keyword Optimization: electrical conductivity of aluminum, corrosion-resistant aluminum, lightweight conductive metal

- Data Points: “Aluminum offers 61% the conductivity of copper at just 30% of its weight”.

Conclusion and Purchasing Tips

To fully leverage the benefits of aluminum in your electrical projects, consider the specific application requirements and choose reliable suppliers. For high-quality aluminum busbars, battery enclosures, and electrical components, ensure consistent quality and technical support.