Samples available for most products

5% discount on bulk purchases

Global Sea Freight Services

Inquiries answered within 24 hours

6061 aluminum tube is a heat-treated Al-Mg-Si aluminum alloy tube. After heat treatment, the MgSi alloy has high strength and hardness, good formability, weldability, machinability, and light weight. It has excellent comprehensive performance and is widely used in bicycle frames, ski poles, golf clubs, auto parts, aviation structural parts and medium and high strength use requirements. It is one of the very important aluminum alloy materials in the manufacturing field and aerospace.

| Description | Temper | OD (in) | Wall Thickness (in) |

|---|---|---|---|

| 6061 T4 Aluminum Round Tube 0.39(OD)x0.04(WA) | T4 | 0.39 | 0.04 |

| 6061 T4 Aluminum Round Tube 0.47(OD)x0.08(WA) | T4 | 0.47 | 0.08 |

| 6061 T4 Aluminum Round Tube 0.63(OD)x0.06(WA) | T4 | 0.63 | 0.06 |

| 6061 T4 Aluminum Round Tube 0.79(OD)x0.2(WA) | T4 | 0.79 | 0.2 |

| 6061 T4 Aluminum Round Tube 1.1(OD)x0.24(WA) | T4 | 1.1 | 0.24 |

| 6061 T4 Aluminum Round Tube 1.5(OD)x0.35(WA) | T4 | 1.5 | 0.35 |

| 6061 T4 Aluminum Round Tube 1.97(OD)x0.51(WA) | T4 | 1.97 | 0.51 |

| 6061 T4 Aluminum Round Tube 2.76(OD)x0.59(WA) | T4 | 2.76 | 0.59 |

| 6061 T4 Aluminum Round Tube 3.15(OD)x0.59(WA) | T4 | 3.15 | 0.59 |

| 6061 T4 Aluminum Round Tube 3.94(OD)x1.18(WA) | T4 | 3.94 | 1.18 |

| 6061 T4 Aluminum Round Tube 5.12(OD)x1.18(WA) | T4 | 5.12 | 1.18 |

| 6061 T4 Aluminum Round Tube 6.3(OD)x2.36(WA) | T4 | 6.3 | 2.36 |

| 6061 T4 Aluminum Round Tube 7.87(OD)x2.36(WA) | T4 | 7.87 | 2.36 |

| 6061 T4 Aluminum Round Tube 9.06(OD)x2.76(WA) | T4 | 9.06 | 2.76 |

| 6061 T4 Aluminum Round Tube 10.24(OD)x3.15(WA) | T4 | 10.24 | 3.15 |

| 6061 T4 Aluminum Round Tube 12.2(OD)x1.38(WA) | T4 | 12.2 | 1.38 |

| 6061 T4 Aluminum Round Tube 14.96(OD)x2.17(WA) | T4 | 14.96 | 2.17 |

| 6061 T6 Aluminum Round Tube 0.39(OD)x0.04(WA) | T6 | 0.39 | 0.04 |

| 6061 T6 Aluminum Round Tube 0.47(OD)x0.08(WA) | T6 | 0.47 | 0.08 |

| 6061 T6 Aluminum Round Tube 0.63(OD)x0.06(WA) | T6 | 0.63 | 0.06 |

| Alloy | 6061 |

| Temper | T4,T6 |

| Standard | ASTM B221,ASTM B210,ASTM B483 ,ASTM B429,ASTM B241,ASTM B308/B308M,ASTM B547(👉Click for details) |

| OD | 0.98″–1.10″(25mm-28mm) |

| WT | 0.02″–2″(0.5mm–50mm) |

| Length | Standard length 400-700mm, up to 30 meters, support custom length or cutting |

| Tube Type | Extruded / Cold Drawn / Seamless |

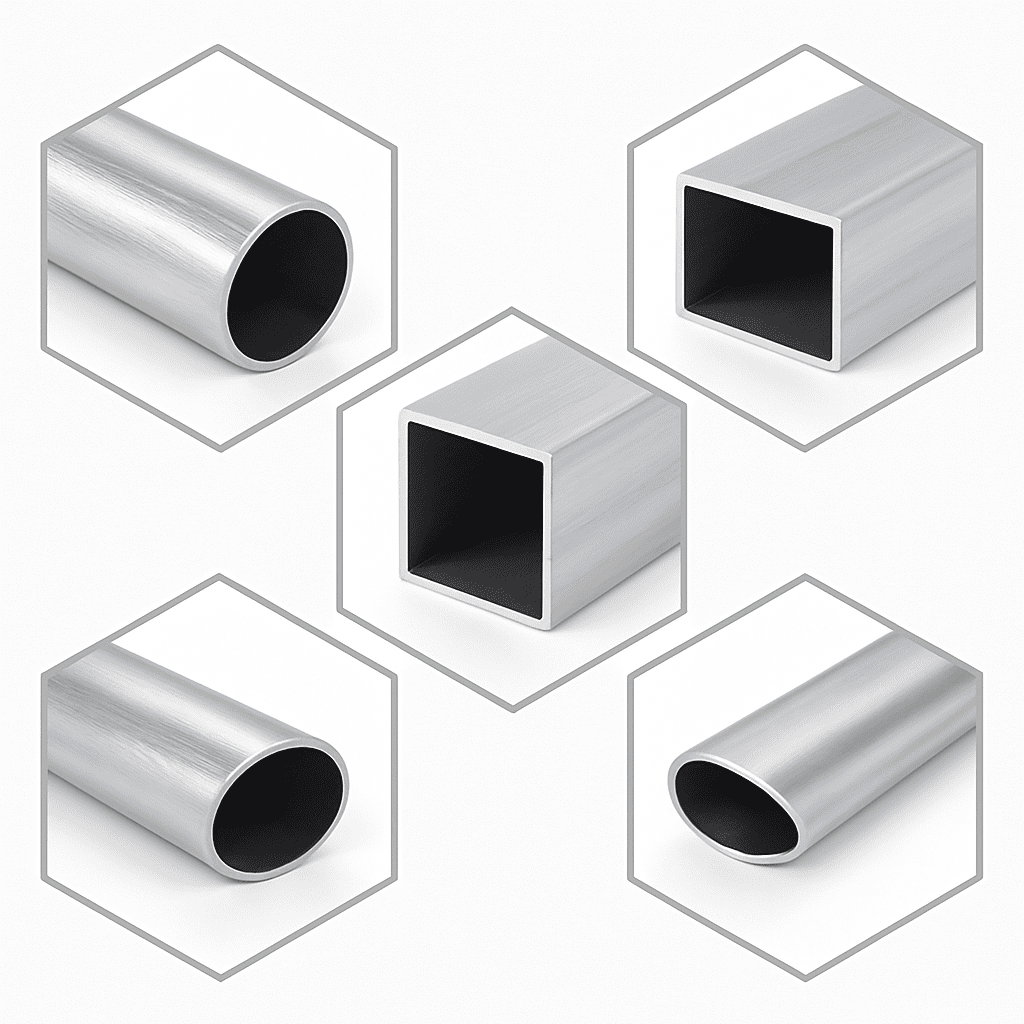

| Shape | Round,Square,rectangular,oval,hexagonal (👉Click for details) |

| Surface Treatment | Anodizing, Powder Coating, Polishing, Brushed Finish, Sandblasting etc. |

| Color | Silver, Black, Bronze, Champagne, Red, Gold, Grey, or Customized |

| Processing Services | CNC Cutting, Drilling, Welding, Bending, Tapping, Etching, Custom Machining(👉Click for details) |

| Packaging | Plastic Film, Bundling, Wooden Box, Pallet, or Customized |

| Application Fields | bicycle frame, ski poles, golf clubs, auto parts, aviation structural parts |

| Certification | ISO 9001, SGS, RoHS, Mill Test Report |

| Cu | 0.15–0.40 |

| Mn | 0.15 |

| Mg | 0.8–1.2 |

| Zn | 0.25 |

| Cr | 0.04–0.35 |

| Ti | 0.15 |

| Si | 0.4–0.8 |

| Fe | ≤0.7 |

| Al | Balance |

| Temper | Wall Thickness (mm) | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A (%) | Elongation A50mm (%) | Hardness (HBW) |

|---|---|---|---|---|---|---|

| T6 | ≤5 | ≥260 | ≥240 | ≥9 | ≥7 | ≥95 |

| T6 | 5–25 | ≥260 | ≥240 | ≥10 | ≥8 | ≥95 |

| Application Type | Standard Code | Applicable Form & Temper |

|---|---|---|

| Extruded structural tubing | ASTM B221 | 6061‑T6 / T6511 extruded round tubes for structures |

| Structural extruded tube | ASTM B429 | Hollow extruded structural tubes (non-pressure) |

| Seamless extruded tubing | ASTM B241 | Seamless pipes for pressure systems or hydraulic use |

| Cold drawn seamless tube | ASTM B210 | Drawn tubes for general or pressure applications |

| Drawn tubing (general use) | ASTM B483 | General-purpose cold drawn aluminum tubes |

| Aerospace drawn tubing | AMS WW-T-700/6 | High-precision 6061-T6 cold drawn tubes |

| Aerospace extruded tubing | AMS QQ-A-200/8 | 6061-T6511 extruded structural tubes |

| European material standards | EN 573‑3 / EN 754‑2 | European alloy composition and dimensional tolerance |

| Japanese industrial standard | JIS H4080 | Aluminum alloy extruded / drawn tube standards |

Bicycle Frames

Due to its high strength-to-weight ratio and corrosion resistance, 6061 aluminum tubing is widely used in manufacturing lightweight and durable bicycle frames.

Automotive and Motorcycle Parts

Used in drive shafts, chassis components, roll cages, and exhaust systems for reduced weight and enhanced performance.

Aerospace Structures

Suitable for structural tubing in aircraft and UAVs, especially in non-critical applications that demand strength with light weight.

Marine Equipment

Ideal for masts, railings, ladders, and structural supports thanks to its excellent corrosion resistance in saltwater environments.

Industrial Machinery

Commonly used in pneumatic and hydraulic systems, conveyor rollers, and mechanical support structures.

Construction and Architecture

Applied in lightweight frames, railings, scaffolding, window/door frames, and structural components.

Furniture and Interior Design

Utilized in modern furniture frames, display racks, and decorative structures requiring strength with a clean finish.

Sports and Outdoor Equipment

Used in trekking poles, tent frames, camera tripods, and other high-strength portable gear.

Heat Exchangers and Cooling Systems

Excellent thermal conductivity makes it useful for tubing in heat sinks, radiators, and HVAC systems.